Application of High-Speed Glazed Tile Roof Sheet Roll Forming Machine

This advanced roll-forming system produces high-quality roof sheets essential for diverse architectural applications. Ideal for steel-framed structures, it serves:

- Industrial complexes & warehouses

- Commercial centers & retail spaces

- Sports arenas & hospitality venues

- Residential projects & greenhouses

Custom configurations ensure perfect alignment with your architectural specifications.

Pioneering Smart Manufacturing Technology

As industries embrace unmanned smart factories with IoT integration, Zhongtuo’s Glazed Tile Machine leads this transformation. Develop, our system recently completed successful commissioning for an Italian client.

Key Technological Advantages:

- Predictive Maintenance System

Our proprietary remote monitoring platform anticipates maintenance needs, minimizing downtime through real-time diagnostics.

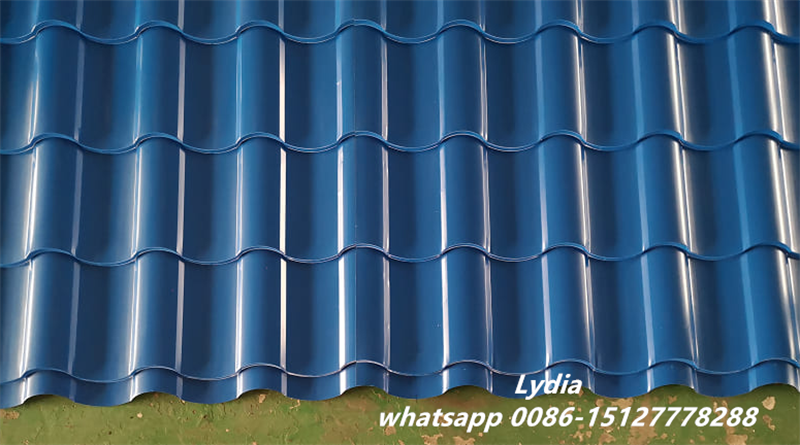

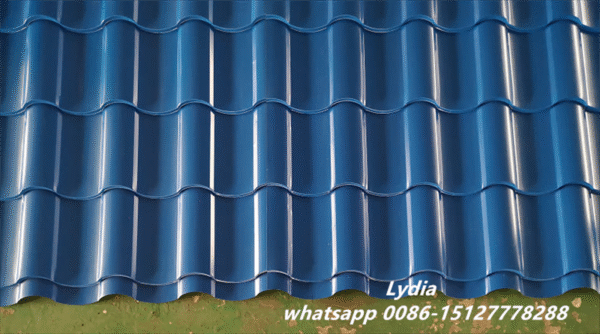

- Weather-Tight Performance

Interlocking panels eliminate water/light penetration with reversible overlapping for versatile installations.

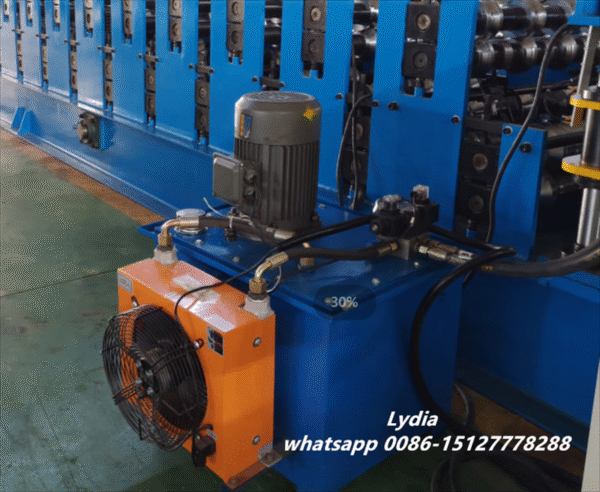

- Continuous Operation Capability

Industrial-grade components (plunger pumps, accumulators, oil coolers) ensure 24/7 production stability

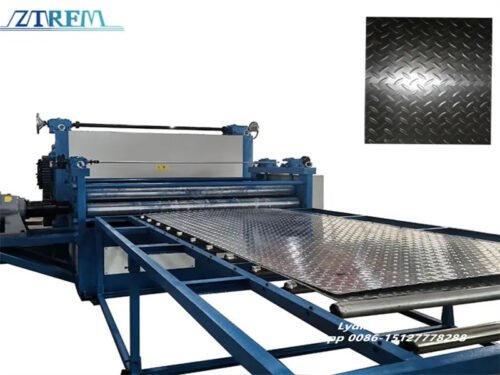

Production Workflow

Coil Unwinding → Guided Feeding → Material Leveling → Precision Roll Forming → PLC Control → Embossing Station → Hydraulic Cutting → Finished Product Output

Here is your Technical Specifications section in table format

| Category | Parameters |

| Material | Pre-painted steel, galvanized steel, aluminum-coated steel |

| Thickness Range | 0.2 – 0.8 mm |

| Roller System | 13-stage forming (customizable), 45# steel rollers with chromium plating |

| Output Speed | 15 – 20 m/min (excluding embossing process) |

| Drive System | Ø75 mm shafts made of 40Cr alloy steel, chain-driven, single-station operation |

| Control | Mitsubishi PLC and frequency converter |

| Cutting | Hydraulic shear equipped with Cr12Mov blades (quenched to HRC 58-62° hardness) |

| Power Supply | 415V / 3 Phase / 50 Hz (customizable) |

| Main Motor Power | 7.5 kW |

| Hydraulic Unit | 3 kW |

Competitive Advantages

Adjustable Manufacturing

Modify step length/height during production for design flexibility

Certified Performance

CE-compliant & patented technology meeting European standards

High-Yield Production

Achieve 10m/min output speeds with precision tolerances

Rapid Deployment

Popular profiles available from stock for immediate shipment

Why Professionals Choose Our System

The combination of IoT-driven maintenance and precision forming allows contractors to deliver complex roof systems with reduced labor costs and material waste. Reversible panel design accommodates unique architectural geometries while maintaining superior weather resistance.

This version maintains all technical specifications while:

- Using active voice & construction industry terminology

- Grouping information into logical segments

- Highlighting operational benefits over generic features

- Incorporating natural transitions between technical sections

- Enhancing readability through parallel structure and consistent formatting

- Emphasizing ROI-driven advantages for commercial decision-makers

Reviews

There are no reviews yet.