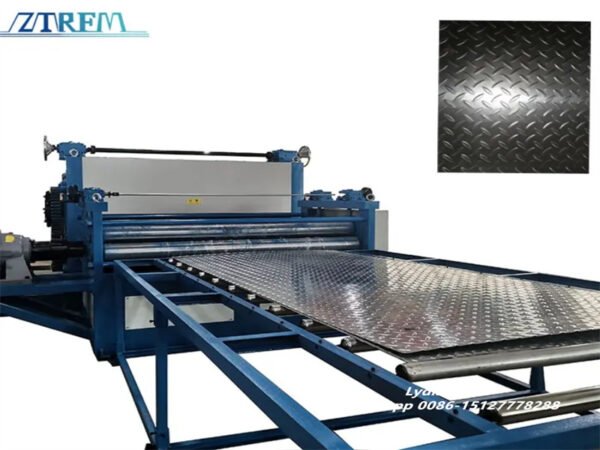

Advanced Metal Embossing Technology, Beyond visual enhancement, embossing fundamentally transforms material properties by permanently reshaping metal substrates. This cold-forming process:

Reinforces structural integrity, enabling thinner gauges (0.2-5.0mm) to achieve equivalent strength to heavier materials

Upcycles rejected stock: Converts flawed coils into premium-grade product

Dual-functional output: Combines decorative textures with measurable mechanical improvements

Process Methodology

Unlike superficial coating-based texturing, our deep-material deformation:

Increases stiffness by 30-50%

Enhances fatigue resistance

Maintains full metal ductility

| System Type | Capabilities |

| Standalone Embosser | Retrofit for existing lines |

| Integrated Line | Uncoiler → Embossing → Recoiler |

| Roll Forming Combo | Pattern + profile forming in one pass |

Technical Specifications

Material Range: Aluminum • Pre-painted steel • Stainless steel • Copper • Galvanized

Thickness Capacity: 0.2-3.0mm (standard) • Up to 5.0mm (custom)

Pattern Types: Anti-slip • Architectural • Branding • Structural reinforcement

Production Speed: 20-45m/min (rolling method) vs 8-12m/min (stamping)

Industrial Applications

- Building Systems – Elevator interiors • Security doors • Facade cladding

- Transportation – Vehicle flooring • Container walls

- Consumer Durables- Appliance panels • Commercial refrigeration

- Infrastructure- Platform decking • Safety stair treads

Why Choose Our Systems?

Material Efficiency: 18% lighter gauges meet the same load ratings

Pattern Precision: ≤0.1mm depth consistency

Smart Manufacturing: IoT-enabled predictive maintenanc

Replaced 1.2mm plain steel with 0.8mm embossed equivalent in garage door production, reducing weight by 33% while increasing panel rigidity.

Reviews

There are no reviews yet.