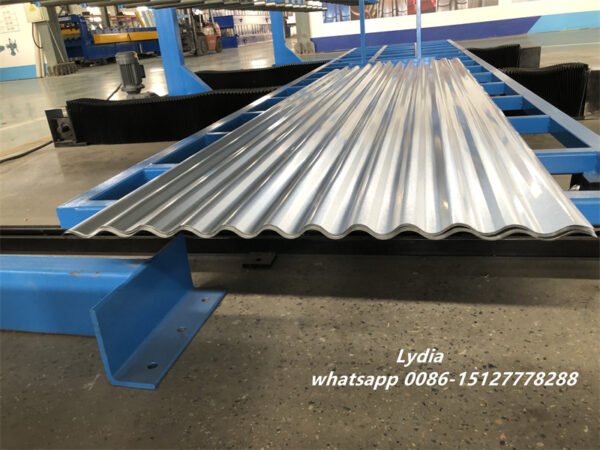

Revolutionizing Thin Plate Corrugated Roofing Production

In the roofing sheet manufacturing industry, producing high-quality corrugated roof panels from ultra-thin materials (0.18–0.28mm) has long been a technical challenge. Traditional segmented forming methods often result in triangular deformation, visible joint marks, and low productivity due to manual handling between stations.

Zhongtuo’s Dominican 70m/min Thin Plate Corrugated Roof Sheet Roll Forming Machine provides a complete automation solution that overcomes these limitations, integrating all processes into one continuous production line:

Decoiling → Precision Forming → Servo Tracking Cutoff → Automatic Stacking

This high-speed corrugated metal roofing sheet machine achieves a production throughput of 70m/min (equivalent to 23 panels per minute for 3m length panels), offering a smooth and efficient forming process with superior surface quality and dimensional accuracy.

Core Advantages & Technological Highlights

- True-Radius Curvature Technology

Delivers precision arc forming with 300% better curvature retention, eliminating triangular deformation and ensuring smooth, aesthetic panel profiles. - Ultra-Thin Material Processing

Specially engineered tension control system prevents wrinkling and distortion during forming, perfectly suited for thin gauge steel roofing from 0.18to 0.28mm. - Smart Automation & IoT Integration

Equipped with Siemens PLC and Data Neuron System for real-time spindle vibration monitoring, thermal anomaly detection, and predictive maintenance alerts—guaranteeing 92% uptime and long-term reliability.

Machine Composition of the corrugated metal roof panel machine

Our roofing sheets roll forming machine consists of:

- Decoiler

- Feeding and leveling device

- Pre-shear unit

- Roll forming system

- Hydraulic post cutting

- Run-out table

- Hydraulic station

- PLC control system

Technical Configuration & Benefits

| 0.18-0.8mm Thin Aluminum 50m/min High Speed Corrugated Roof Sheet Roll Forming Machine | |

| Raw Material | PPGI,PPGL |

| Material thickness: (0.18-0.28 mm) | |

| Machine Frame | 400 mm H beam structure, with casting iron brand structure |

| Material Of Rollers | High grade 45# forged steel,Chromed treatment |

| Forming Stations | Roller stations :21 rows |

| Diameter Of Shafts | Φ80mm Solid |

| Material Of Shafts | High Grade 45#,With Heat Treatment |

| Forming Speed | 70 M/Min |

| Voltage | 380v/50hz/3p (As Requested) |

| Transmission Way | By gear box |

| Main Motor | 15 KW |

| Cutting Blade Material | Gcr12 quenched treatment |

| Cutting Type | hydraulic tracking cutting |

| Driving Method | By pillar type Cylinder |

Applications & Market

This high-speed corrugated roofing roll-forming machine is widely applied in the Dominican Republic market, as well as in architectural facades, decorative wall panels, and industrial roofing projects.

Its advanced automation, precision forming, and seamless curvature make it the preferred solution for companies seeking higher productivity, reduced waste, and premium sheet quality.

Why Choose Zhongtuo

Zhongtuo integrates smart manufacturing with global remote monitoring, multi-network connectivity (China, USA, Canada, Russia, Dominican Republic), and cutting-edge data analytics to ensure stable performance and lifetime support.

Our corrugated roof sheet roll forming line not only meets but exceeds modern production demands—time-saving, labor-saving, and efficiency-driven—helping manufacturers stay ahead in an increasingly competitive market.

Keywords optimized: corrugated roof sheet roll forming machine, thin plate roofing sheet machine, automatic metal roofing forming line, high-speed roll forming machine, Dominican market, corrugated metal roof panel machine.

Reviews

There are no reviews yet.