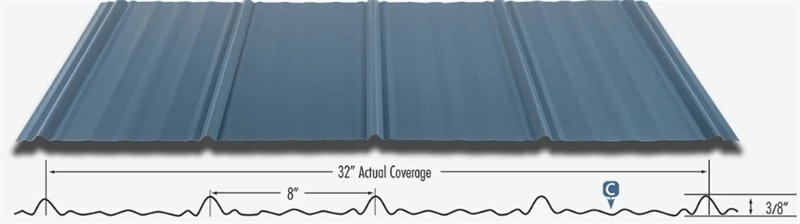

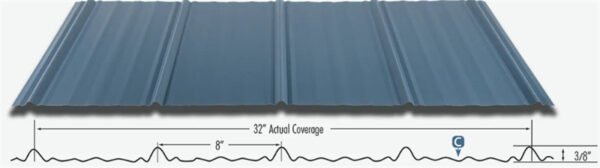

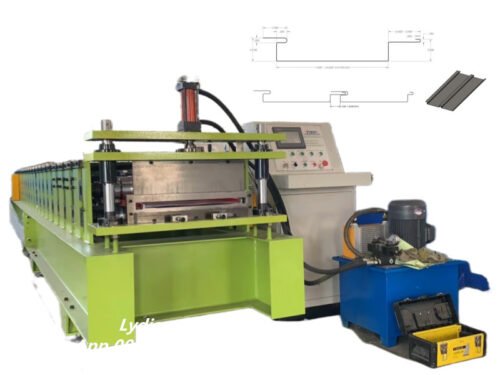

Zhongtuo Fully Automatic Low Rib/Weathershield Roof Panel Roll Forming Machine

As the construction industry rapidly advances toward industrialized and intelligent building methods, roofing systems have become a decisive factor affecting project timelines, cost control, and long-term performance. The manual production of trapezoidal roof sheets often results in unstable quality, slow output, and difficulty in meeting the strict tolerances required for large-scale steel structure projects.

To address these challenges, the fully automatic trapezoidal roof panel roll forming machine introduces a modern, intelligent production solution. Through automated feeding, precision forming, and accurate cutting, it significantly enhances productivity while ensuring the consistent production of high-quality roofing panels. As technology continues to evolve, this equipment will remain essential to the development of greener and smarter construction environments.

Technical Specifications of Low Rib/Weathershield Roof Panel Machine

| Category | Details |

|---|---|

| Forming Material | PPGI / GI / Aluminum |

| Material Thickness | 0.4–0.7mm |

| Material Width | Customized |

| Decoiler Options | Hydraulic automatic decoiler / Standard manual decoiler (free) |

| Roller Stations | 10–20 rows (as required) |

| Shaft Diameter | 70mm solid shaft |

| Roller Material | 45# steel with hard chrome plating |

| Machine Frame | 350H steel |

| Drive Chain Size | 1.2 inch |

| Machine Dimensions | 10000 × 1600 × 1600mm (customizable) |

| Machine Weight | 4–6T |

| Cutting System | Automatic cutting, Cr12MoV blade, no deformation |

| Motor Power | 5.5KW |

| Hydraulic Power | 7.5KW |

| Voltage | 380V, 50Hz, 3-phase (optional customization) |

| Control System | Industrial PLC with touch-screen, multi-language |

| Forming Speed | Up to 20m/min (depends on profile & thickness) |

Zhongtuo Machine Core System Structure of Low Rib/Weathershield Roof Panel Machine

The machine functions as a complete automated production line designed around continuous feeding, precise forming, and accurate cutting.

1. Automatic Material Feeding

A hydraulic tensioning mechanism stabilizes coil release and prevents wrinkling or deviation, ensuring smooth entry into the forming section.

2. Leveling System

Multiple precision rollers correct coil flatness with intelligent pressure adjustment, maintaining tolerance within ±0.5mm.

3. Roll Forming Host

Using 20–30 progressive forming stages, high-strength alloy rollers (HRC55+) guarantee:

- consistent wave height & pitch ≤ 0.3mm

- longer roller lifespan

- reduced maintenance frequency

4. Servo / Hydraulic Cutting

Fixed-length cutting is achieved with ±1mm accuracy. Operators simply input the required length and quantity through the PLC interface.

5. Smart Control Platform

The industrial-grade system enables:

- real-time monitoring

- automated fault alarms

- parameter memory & batch production settings

No programming knowledge is required, reducing training time and human error.

One-Click Workflow

- Load coil and set parameters

- Automatic feeding and leveling

- Progressive roll forming

- Precision cutting and discharge

- Optional automatic stacking and data export

Production data can be stored or exported for cost tracking and maintenance planning.

Key Advantages of ZTRFM Low Rib/Weathershield Roof Panel Machine

1. Higher Output

- Manual production: 500–800 m²/day

- Automatic line: 2000–5000 m²/day

→ 3–5× efficiency increase

2. Stable and Accurate Quality

- Qualification rate ≥ 99%

- Eliminates edge warping, uneven rib formation, and length deviation

3. Reduced Labor and Material Costs

- Only 1–2 operators required

- Material utilization increases from 90% → 98%+

- Annual savings: RMB 500,000–1,000,000 (based on 3000 m²/day)

4. Fast Specification Change

Roller replacement takes just 1–2 hours, supporting:

- different wave heights and widths

- PPGI, GI, aluminum, and more

This flexibility improves delivery capability and market competitiveness.

Application Areas of Zhongtuo Machine

The machine is widely used in:

Industrial facilities & warehouses

Large-area roofing with high sealing performance

Public steel-structure buildings

Airport terminals, stadiums, exhibition centers

Residential & commercial roofing

Villas, modular homes, shopping complexes with enhanced insulation performance

Reviews

There are no reviews yet.