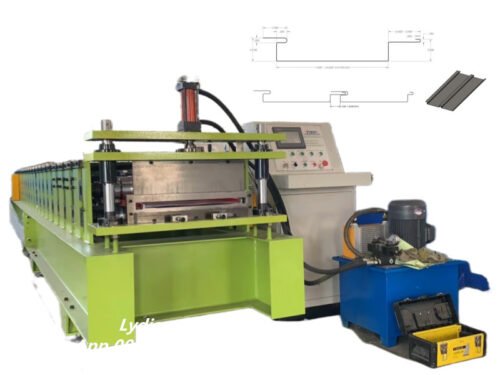

Wall Cladding Metal Roll Forming Machine

The Zhongtuo Wall Cladding Metal Roll Forming Machine is specially developed to manufacture modern decorative and protective metal wall panels with high precision and stability.

Metal wall cladding is becoming increasingly popular for architectural applications around the world — from stylish restaurant facades in Itaewon, South Korea, to large commercial buildings in China, Saudi Arabia, and across Europe.

Compared with traditional cement walls, Zhongtuo machine wall cladding panels offer better durability, visual appeal, and faster installation.

Main Advantages of Zhongtuo Wall Cladding Roll Forming Machine

1. High Efficiency and Stability

The ztfrm wall panel machine adopts 28 forming stations with a split-forming system that forms each rib gradually.

This method ensures precise shaping, correct rib angles, and a perfectly smooth surface without waves or scratches. It’s an ideal solution for producing high-end wall cladding panels with a premium appearance.

2. Dual Cutting Configuration

To improve flexibility and production efficiency, Zhongtuo machine designs the equipment with both front and rear hydraulic shearing systems.

- Front Shear: Prepares coil length accurately before forming.

- Rear Shear: Ensures precise cutting after forming with no deformation.

Operators can easily switch between the two shearing modes according to their needs, making production more intelligent and user-friendly.

3. Advanced PLC Control System

The system uses an imported Delta PLC controller, enabling easy parameter configuration for forming speed, cutting length, and profile precision.

All electrical parts use aviation-grade connectors, providing a secure and efficient control environment.

This design ensures stable performance and makes later maintenance or debugging easier for global users of Zhongtuo and ztfrm machines.

Technical Specifications of Zhongtuo Wall Cladding Machine

| Item | Specification |

|---|---|

| Material | HR, CR, Galvanized, Pre-painted Coil |

| Thickness | 0.5–0.7 mm |

| Input Coil Width | 607 mm (approx.) |

| Roller Stations | 28 stations |

| Working Speed | 20 m/min |

| Roller Shaft Diameter | 70 mm |

| Base Plate Thickness | 20 mm |

| Roller Material | 45# Steel with Hard Chrome |

| Transmission | 1-inch Chain Drive |

| Motor Power | 7.5 kW |

| Shearing Method | Hydraulic Cutting |

| Cutting Accuracy | ±1 mm |

| Blade Material | Cr12 |

Machine Components and Features

Manual Decoiler

Equipped with a handwheel and braking system, the manual decoiler allows operators to unwind material smoothly and safely, with reliable emergency control.

Feeding Section

- Multiple supporting rollers ensure smooth material feeding.

- Adjustable handwheels simplify width changes.

- Both upper and lower layers include manual cutters for easy trimming.

- Dual external gears deliver stable power transfer for faster feeding performance.

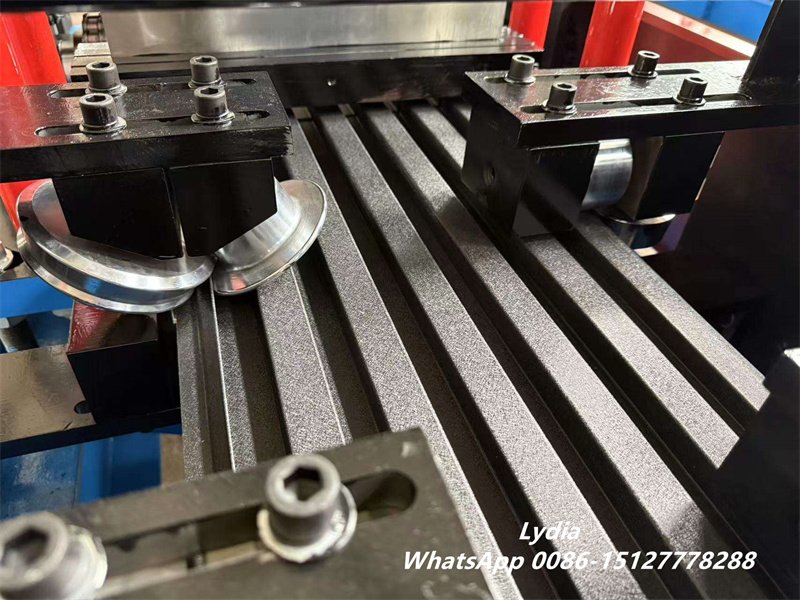

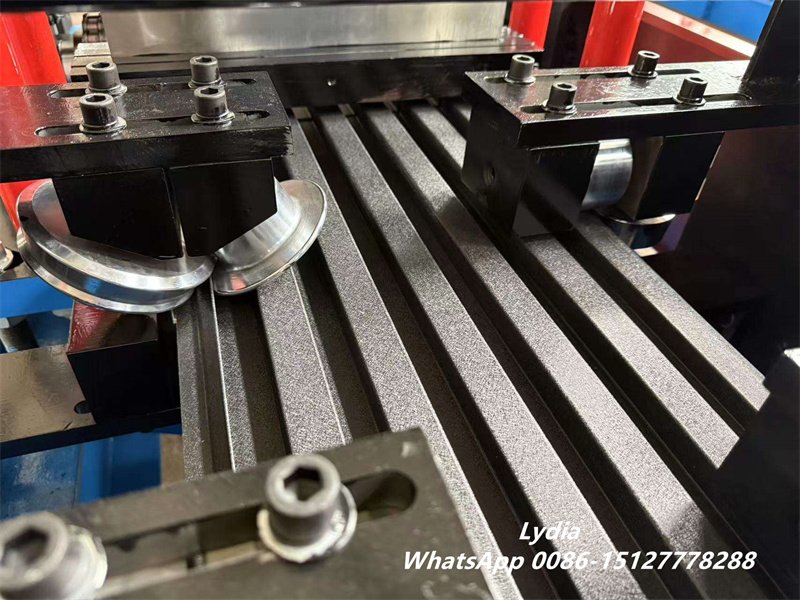

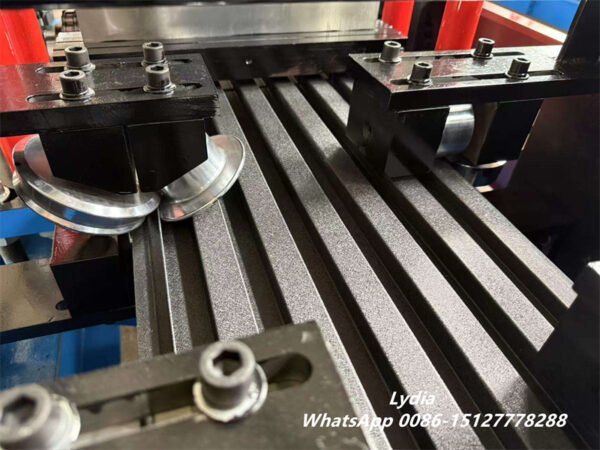

Forming Unit

Zhongtuo adopts integrated forming technology—first forming the profile, then rolling to final curvature—to protect the paint and zinc layers.

The roller shafts are locked by keys and keyways, ensuring consistent accuracy and high-strength resistance under continuous load.

Rollers and Shafts

- 28 rows of chrome-coated 45# steel rollers for precision shaping.

- Automatic lubrication system to protect coating layers.

- Heat-treated shafts (Ø80mm) provide excellent wear and corrosion resistance.

This configuration makes the ztfrm roll forming machine both durable and precise.

Chain Transmission System

Compact double-chain drive (1 inch) ensures reliable torque transmission and efficient use of space.

The 7.5 kW motor provides strong power, while a built-in chain tensioner extends service life and stability.

Cutting Device

The double-guide column cutting structure uses 8.8-grade bolts and automatic oiling, offering smooth, clean cutting with reduced maintenance needs.

PLC Control Cabinet

- Siemens electronic control system with remote operation support.

- Touchscreen interface for intuitive operation.

- Multi-language customization available.

- Aviation connectors for quick installation and secure wiring.

Hydraulic Station with Accumulator

The hydraulic system includes an accumulator that stabilizes pressure and increases shearing speed, ensuring steady operation and reducing vibration during production.

Why Choose Zhongtuo Machine

- Over 15 years of manufacturing experience.

- Certified by ISO9001, CE, and CAS standards.

- Exported to over 90 countries worldwide.

- Customizable profiles, fast delivery, and comprehensive after-sales support.

Zhongtuo continues to lead the roll forming industry with innovative ztfrm machines designed for precision, efficiency, and long-term reliability.

The Zhongtuo Wall Cladding Metal Roll Forming Machine combines intelligent automation, robust engineering, and user-friendly operation. Whether for modern commercial façades or architectural interiors, this ztfrm roll-forming machine delivers premium quality, aesthetic appeal, and efficient performance.

Reviews

There are no reviews yet.