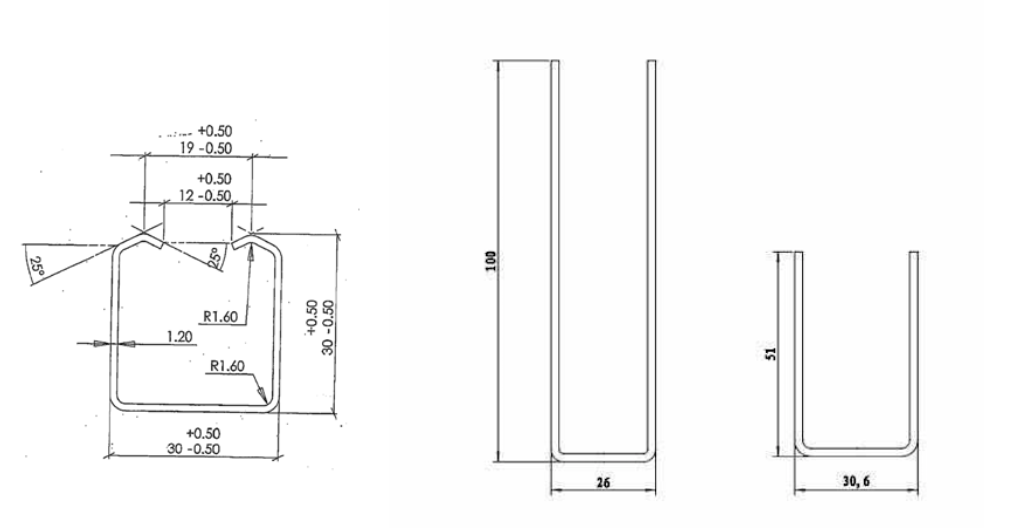

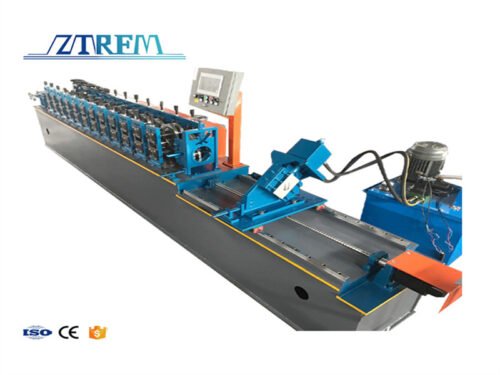

The U Channel Sliding Guide Rail Roll Forming Machine is a high-performance equipment designed for the continuous production of guide rails used in rolling shutter doors, sliding doors, window frames, and garage doors. With advanced roll forming technology, this machine ensures smooth and accurate shaping of U channel guide rails from galvanized steel or aluminum.

Our roll forming lines are widely recognized for high speed, durability, and precision, making them the preferred choice for manufacturers in Africa, the Middle East, Europe, and Asia.

Key Features & Advantages of U Channel Sliding Guide Rail Roll Forming Machine

-

Versatile Material Processing: Works with galvanized steel and aluminum coils with thickness from 1.5mm to 2.5mm.

-

High Speed Production: Maximum forming speed of 10–20m/min; with hydraulic punching, production speed is 2–3m/min.

-

Precision Forming: Equipped with 16 roller stations using GCr15 steel rollers and 60mm shafts, ensuring accuracy and long service life.

-

Strong Power System: Main motor 7.5 kW, hydraulic station 4 kW, driven by 1-inch single chain for stable performance.

-

Durable Cutting System: CR12 blades with hardness HRC58–62, cutting tolerance within ±1.5mm.

-

Intelligent Control: PLC electrical control system, compatible with 220V, 60Hz, 3-phase or customized on request.

-

Customizable Solutions: Curved U channel rails available based on customer drawings.

Applications of U & J Channels

U and J channels produced by this roll forming machine are widely used in:

-

Shutter door tracks & guide rails

-

Sliding door and window frames

-

Garage door side rails

-

Sign posts, shelf supports, control joints

-

Expansion joints, corner trims, and structural reinforcements

These profiles are essential in providing support, guiding movement, and reducing friction in industrial and architectural projects.

Technical Specifications

| Item | Specification |

|---|---|

| Coil Material | Galvanized steel sheet |

| Thickness | 1.5 – 2.0 mm |

| Punching System | 2 punching molds |

| Line Speed | 0–12 m/min (2–3 m/min with hydraulic punching) |

| Roller Stations | ~16 stations |

| Roller Material | GCr15 steel, heat-treated, 60mm shaft |

| Main Motor Power | 7.5 kW |

| Hydraulic Power | 4 kW |

| Cutting Blade | CR12 quenched |

| Hardness | HRC58–62 |

| Tolerance | ±1.5 mm |

| Control | PLC system |

| Drive Mode | 1-inch single chain |

| Weight | ~5 tons |

Reviews

There are no reviews yet.