High-Precision Eave Strut Roll Former

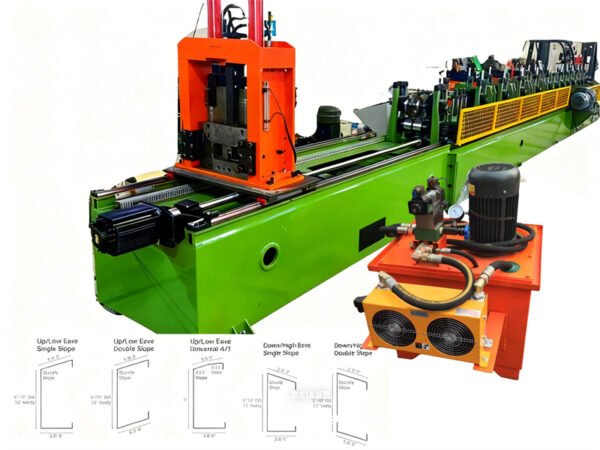

The Automatic Eave Strut Roll Forming Machine produces high-quality 8-inch and 10-inch eave struts for metal buildings, warehouses, and industrial roofing systems. The line runs with full automation, fast forming, and precise punching to deliver consistent accuracy and strong performance.

8-Inch & 10-Inch Eave Strut Forming

To match different profile widths, the roller carriages adjust automatically through motorized movement. No manual positioning is required.

Our demo videos clearly show the equipment forming both sizes—the 10-inch profile first, followed by the 8-inch model.

The entire system produces 2.5-meter eave struts automatically, greatly increasing output and reducing labor intensity.

What Are Eave Struts?

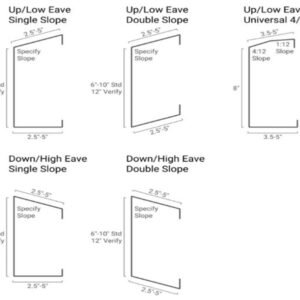

Eave struts are structural members installed at the point where the roof and wall panels meet—the building’s eave line.

Like purlins and girts, they strengthen this connection and support both roof and wall cladding.

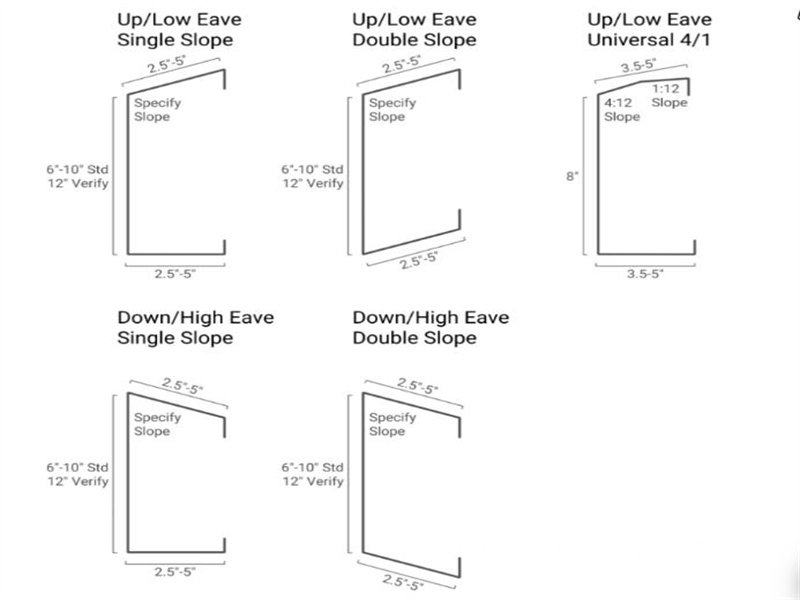

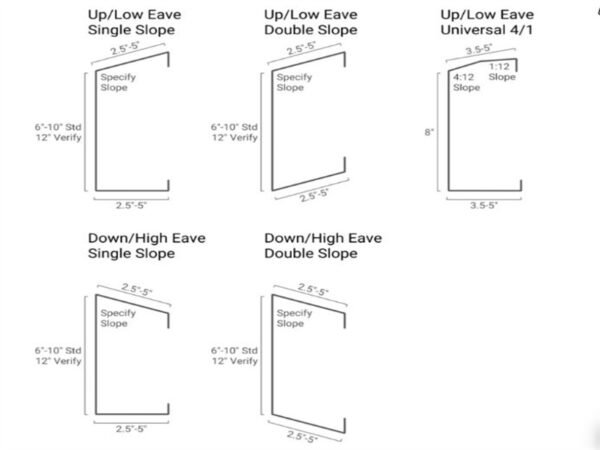

Most eave struts come in a C-shaped profile and appear widely in single-slope and double-slope metal buildings.

They are typically formed into a C-shape and are widely used in single-slope and double-slope metal buildings.

Advantages of Our Eave Strut Roll Forming Machine

Fully Automated Operation

Decoiling → Punching → Cutting → Forming → Stacking

All processes are controlled by PLC for continuous production.

Full Automatic Control System

The PLC system monitors every step of feeding, forming, punching, and cutting to keep the production stable and efficient.

Dual Size Production (8” & 10”)

You can switch between two sizes easily without long downtime, which improves flexibility in daily production.

High Structural Strength

The heavy-duty frame and high-grade rollers support long-term operation and reduce maintenance needs.

Accurate Punching & Cutting

The servo punching unit positions every hole precisely, and the hydraulic cutter delivers clean edges on every piece.

Fast Production Speed

The optimized roll design ensures smooth forming and keeps the production speed high for bulk orders.

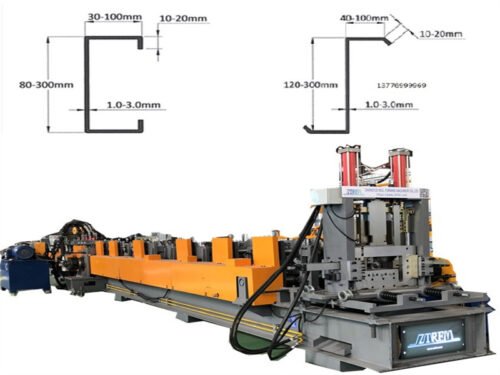

Machine Specifications of Eave Strut Roll Forming Machine

1. General Machine Data

| Parameter | Details |

|---|---|

| Weight | Approx. 15,000 kg |

| Overall Size | 22m × 2m × 1.8m (L×W×H) |

| Machine Color | Blue (main), Yellow (safety) |

2. Raw Material

| Item | Specification |

|---|---|

| Material Type | Galvanized Steel Coil |

| Thickness Range | 1.9–2.6 mm |

| Coil Width | Based on the profile design |

| Yield Strength | 235 MPa |

3. Technical Parameters

| Item | Specification |

|---|---|

| Roller Stations | 20 |

| Shaft Diameter | 75 mm |

| Forming Speed | 10–15 m/min |

| Production Speed | 4–6 m/min |

| Roller Material | GCr15 steel (quenched) |

| Cutter Material | CR12 (heat-treated) |

| Control System | PLC + Inverter |

| Main Motor Power | 18.5 kW |

| Hydraulic Unit Power | 5.5 kW |

| Voltage | Customized |

Eave Strut Product Specifications

Our eave strut line supports multiple building applications and can be customized to your structural requirements.

| Specification | Range |

|---|---|

| Web Size | 7″, 8″, 10″ |

| Flange Size | 4″ |

| Material Finish | Galvanized / Red Oxide |

| Length | 6’ – 50’ (up to 45’ in some facilities) |

Grade 55 steel with G-90 galvanized coating extends service life and ensures resistance to corrosion.

The Automatic Eave Strut Roll Forming Machine offers a high-precision, high-efficiency solution for manufacturing 8″ and 10″ eave struts used in modern steel buildings.

With automated roller adjustment, servo punching, and a strong mechanical structure, the machine boosts productivity, shortens setup time, and delivers long-term reliability.

It is an ideal choice for manufacturers producing steel structures, purlins, girts, and building accessories.

Reviews

There are no reviews yet.