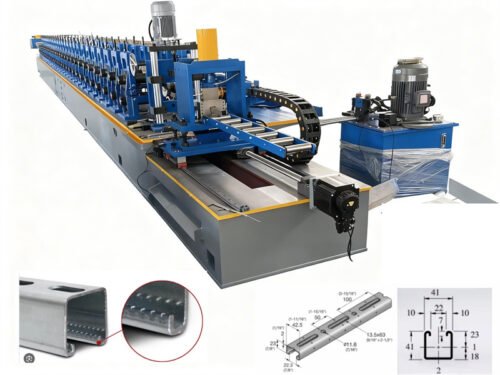

High Speed CU Solar Strut Roll Forming Machine

The High Speed CU Solar Strut Roll Forming Machine is a fully automated production line engineered for manufacturing CU structural profiles used in modern photovoltaic mounting systems. With growing demand for high-efficiency solar installations, manufacturers need equipment that delivers stable speed, tight tolerances, and long-term durability. This CU solar strut roll forming system offers a complete solution from coil handling to final stacking.

Designed for high-volume solar structure production, the line integrates hydraulic decoiling, servo-controlled leveling, isolated punching stations, precision roll forming, and high-speed flying cutting. Its intelligent automation and modular punching system allow fast transitions between different CU channel sizes while maintaining consistent accuracy.

Advanced Roll Forming Technology for Solar CU Profiles

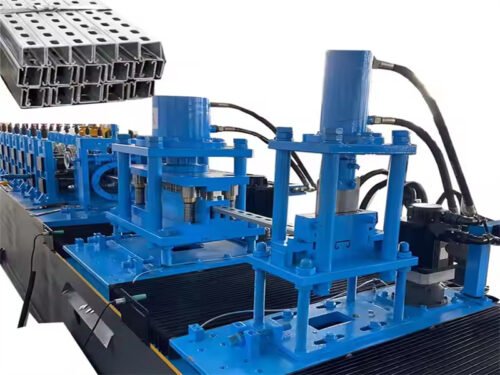

This high-speed solar strut-forming line is equipped with a servo-driven automatic adjustment system, enabling quick width and height changes without manual recalibration. The roll forming section includes multiple precision roller stations that ensure stable shaping of CU profiles, even at high production speeds.

The isolated punch frame features 8 independent punching seats, allowing flexible hole patterns for different solar project requirements. With easy Y-axis adjustments, manufacturers can produce customized CU solar channels, slotted struts, and mounting brackets with minimal downtime.

Technical Parameters of Solar CU Roll Forming Machine

| Item | Specification |

|---|---|

| Thickness | 2.0–4.0 mm |

| Web | 60–180 mm |

| Material | ST37 / ST52 |

| Line Speed with Punch | 30 m/min |

| Decoiler Type | Hydraulic |

| Loading Capacity | 8T |

| Punch Type | Modular stand-alone station |

| Punch Die | 8 units |

| Power Unit Punch | 55 kW + 37 kW |

| Roller Groups | 19 |

| Arbor Diameter | Φ100 mm |

| Motor | 75 kW |

| Roller Support Structure | Pillar type |

| Cutting Type | Cold saw |

| Thickness Adjustment | Magnetic rotation 180° |

| Electricity Consumption | About 230 kW |

High Speed, High Precision, High Reliability

The CU solar strut roll forming machine achieves production speeds of up to 30–60 meters per minute, depending on punching configuration. Its cold-saw flying cutting unit ensures clean cuts and smooth edges, improving installation efficiency in the field.

The entire system is built on a reinforced steel frame with pillar-type roller supports, ensuring vibration-free operation. Robust design, combined with advanced electrical systems and centralized control, guarantees long service life and reliable performance during long production cycles.

This high-efficiency workflow makes the machine ideal for manufacturers supplying large-scale solar farms, EPC contractors, and PV support system distributors.

Ideal Machine for Solar Structure and Strut Channel Manufacturing

Whether producing CU strut channels, solar brackets, mounting rails, or customized structural profiles, this solar mounting channel machine provides unmatched flexibility. Its modular design allows for upgrades such as servo punching groups, automatic stacking systems, and precision laser measurement.

Common applications include:

- Solar panel mounting structures

- Ground-supported PV frames

- Rooftop solar support systems

- Industrial strut channels and support beams

- Utility-scale solar farm assemblies

The combination of high-speed forming, accurate punching, and automated cutting makes it a complete production solution for solar support roll forming lines worldwide.

CU strut roll forming machine

Reviews

There are no reviews yet.