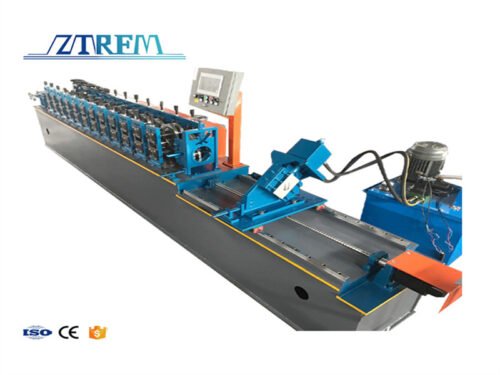

Advanced Automatic Aluminum Door & Window Frame Production Line

Overview

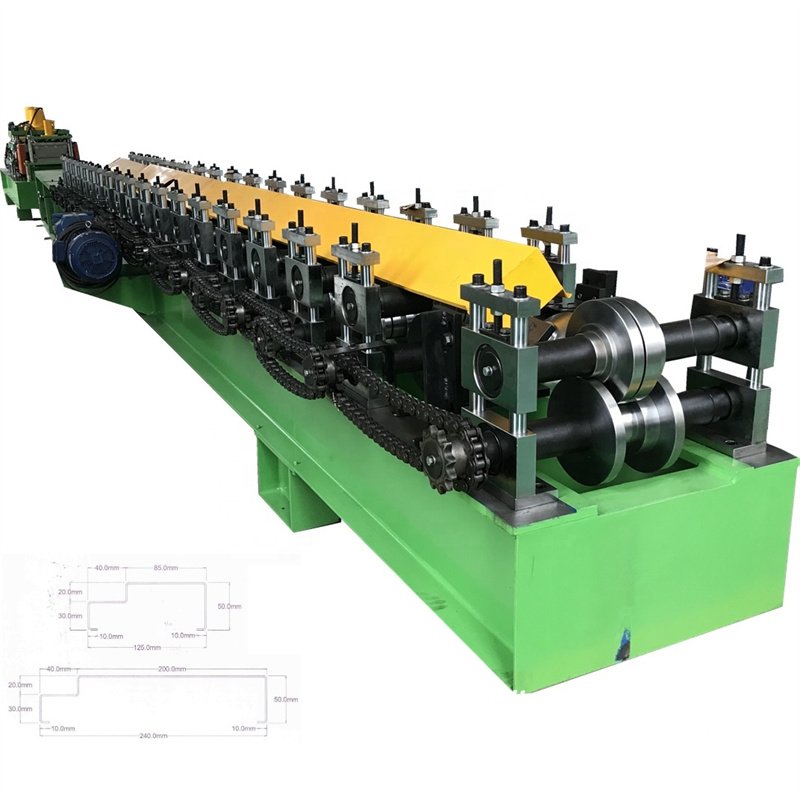

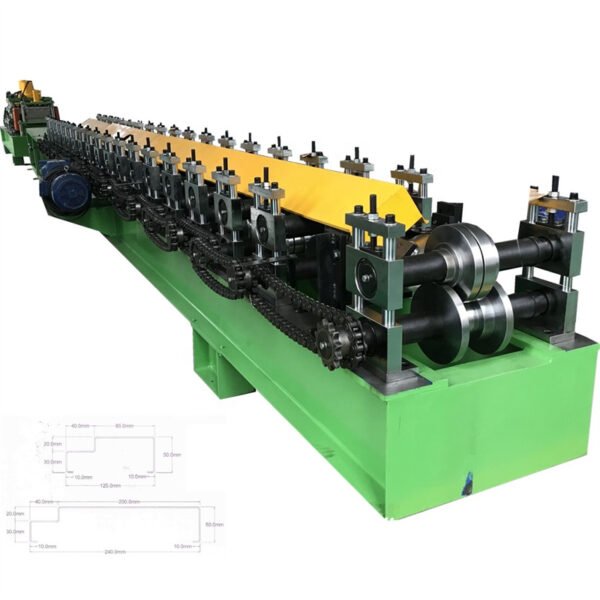

Our fully automated roll forming system specializes in manufacturing precision door and window frames with adjustable width capabilities. Designed for industrial-scale production, this versatile machine handles various metal materials while maintaining exceptional dimensional accuracy.

Punching and pre-cutting device

- Punching device 4 sets

- Punching dies (8 sets)

Material of punching mold: Cr12MoV with quenched treatment

- 1 set of keyholes, 6 sets of folding holes, 1 set of hinge holes

- Pre-shearing device 1 set

Material of cutting blade: Cr12MoV with quenched treatment

Key Features of Aluminum Door & Window Frame Production Line

-

Multi-size adaptability for diverse architectural requirements

-

Integrated punching system for pre-formed holes and notches

-

Heavy-duty construction with 80mm diameter hardened steel shafts

-

Smart control system featuring Delta PLC automation

Material Compatibility

The production line processes:

• Galvanized steel (most popular choice)

• Stainless steel

• Carbon steel

• Copper alloys

• Zinc-coated materials

Technical Specifications of Automatic Aluminum Door & Window Frame Machine

Forming Capacity

| Parameter | Specification |

|---|---|

| Thickness Range | 0.9-1.6mm |

| Width Adjustment | 120-250mm |

| Production Speed | 0-15m/min |

| Length Tolerance | ±1mm/3m |

Mechanical Components

-

18 forming stations with chromium-plated rollers

-

Gear-driven transmission for consistent power delivery

-

Hydraulic cutting system with CR12MoV blades

-

11kW dual-motor configuration

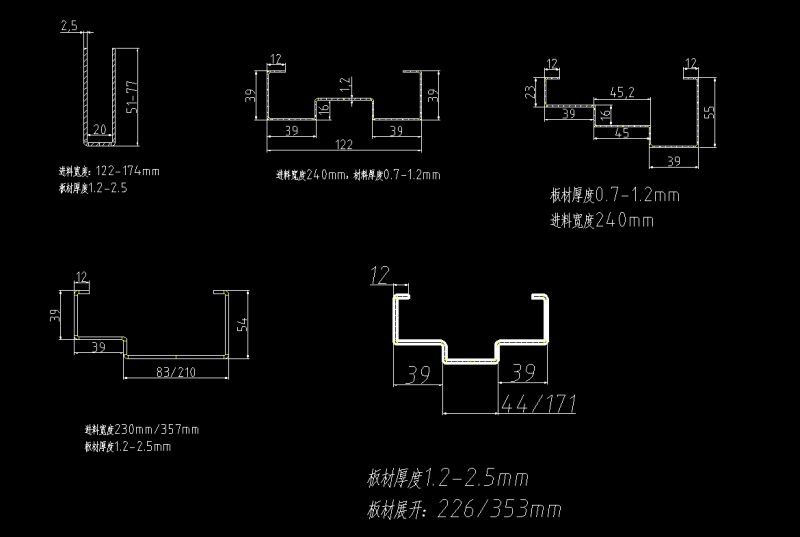

Available Profiles

The machine produces:

-

Security door frames (double rabbet)

-

Modular mullion/transom systems

-

Drywall integration frames

-

Architectural shadow-line profiles

-

Commercial sliding door assemblies

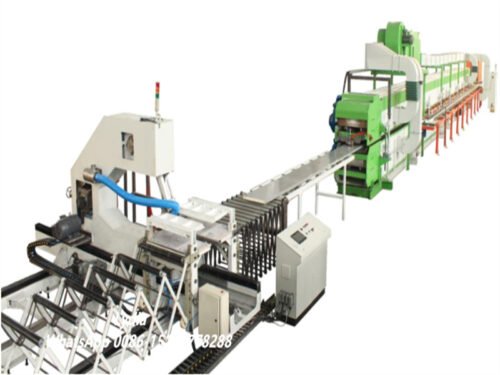

Production Process

-

Material Loading – 3-ton capacity decoiler

-

Precision Leveling – Ensures flat material feed

-

Hole Punching – Custom hole patterns as required

-

Continuous Forming – 18-stage progressive shaping

-

Hydraulic Cutting – Clean, burr-free edges

-

Output Stacking – Automated collection system

Quality Assurance

All components undergo:

-

Stress-relieving temper treatment

-

Anti-corrosion surface finishing

-

Dimensional verification testing

Reviews

There are no reviews yet.