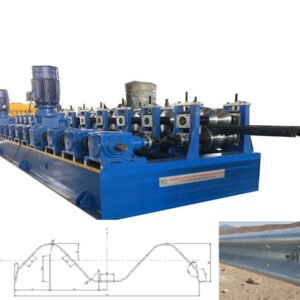

Highway Guardrail Roll Forming Machine

Our fully automated guardrail production line represents the pinnacle of road safety equipment manufacturing technology. Designed for continuous operation, this turnkey solution integrates uncoiling, precision forming, punching and cutting processes to produce W-beam, Thrie-beam, and C-profile guardrails meeting global safety standards.

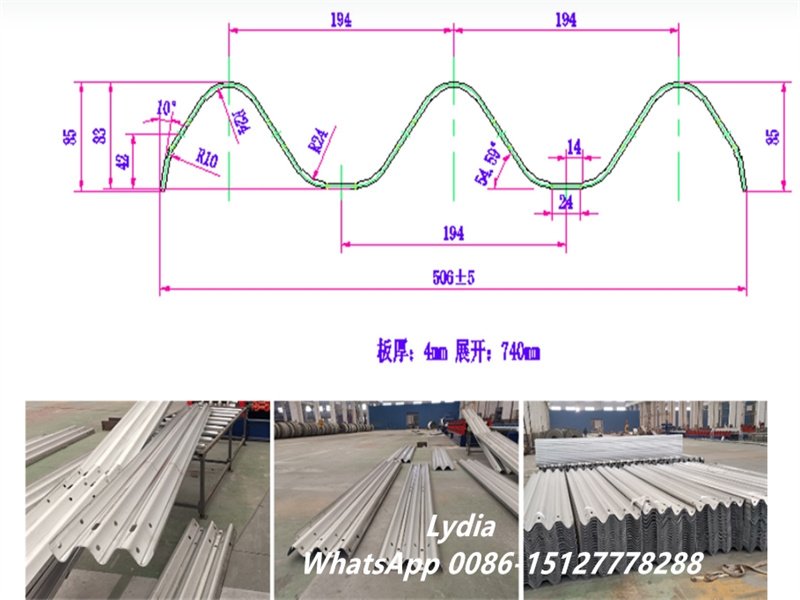

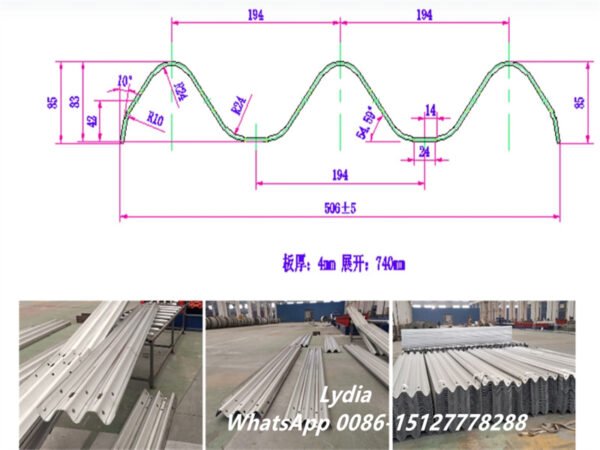

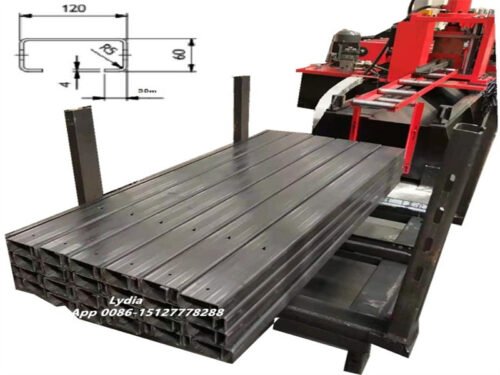

Key Technical Specifications of C Post Profile Forming Machine

| Production Capacity | 15 m/min maximum speed |

|---|---|

| Material Thickness Range | 1.0-5.0 mm |

| Profile Length Capacity | 360mm – 7m |

| Yield Strength | 350-550 MPa |

| Control System | Siemens PLC |

Technical Advantages of the Highway Guardrail Machine

Dual-Profile Production: Switch between W-beam and Thrie-beam with minimal downtime

Precision Engineering: German-standard components (Siemens PLC, SKF bearings)

Energy Efficient: 22kW×2 main drive motors with STANDARD gearboxes

Smart Control: 7″ Siemens HMI with production monitoring

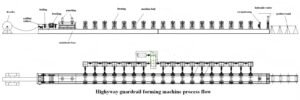

Production Workflow

-

Coil loading → 2. Head welding → 3. Precision leveling → 4. Programmable punching → 5. Multi-stage forming → 6. Length cutting → 7. Automated stacking

Core Components & Features

1. Intelligent Material Handling

-

15T capacity single-cone uncoiler with hydraulic expansion (φ510-760mm)

-

9-roller leveling system (40Cr rollers, HRC48-52°)

-

Servo-controlled feeding with ±0.5mm precision

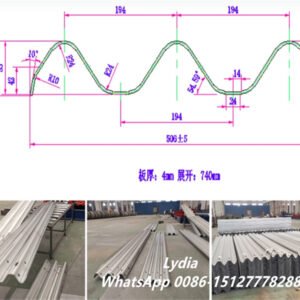

2. Precision Forming Section

-

Dual-profile capability (W-beam & Thrie-beam)

-

17-station forming for main beams

-

12-station forming for C-posts

-

Cr12 rollers (HRC58-62°) on 40Cr shafts

3. Automated Punching System

-

4-column hydraulic press (7kW servo)

-

5 sets of Cr12MoV dies

-

Programmable hole patterns

4. Cutting & Stacking

-

Non-stop hydraulic cutting (±1mm accuracy)

-

Electromagnetic stacking for 350-500mm bundles

-

Automated packing/lifting system

Quality Assurance

-

All critical components ISO-certified

-

100% dimensional inspection capability

-

YUKEN hydraulic system for reliable operation

-

Schneider electrical components for safet

Why Choose Our System?

-

30% higher output than conventional lines

-

20% energy savings through optimized drives

-

Remote diagnostics capability

-

5-year structural warranty

Available for immediate commissioning with full operator training package. Contact our engineering team for country-specific configuration requirements.

Reviews

There are no reviews yet.