This Machine is designed to produce two of the most widely used profiles in metal roofing and building construction: the Ag Panel and the R-Panel. Known for their structural strength, these panels are suitable for both roofing and wall applications.

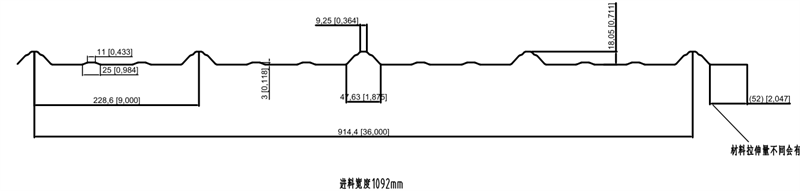

The system processes coil stock up to 42 inches in width (26–29 gauge steel), producing a finished panel width of 38 inches and offering 36 inches of effective coverage when overlapped.

-

The ¾” Ag Panel typically spans 9 inches on center, featuring 5 major ribs with minor ribs positioned between them.

-

The 1¼” R-Panel is generally spaced 12 inches on center and includes 4 major ribs, also with minor ribs in between.

Production Process

Coil Loading Vehicle (optional) → Decoiler (manual/automatic) → Pre-cut Shear (optional) → Feeding & Alignment Stage → Surface Protection Film Application (optional) → Roll Forming Assembly → Precision Length Cutting (Hydraulic/Motor-Driven) → Discharge Conveyor / Automated Stacking Unit (optional)

Constructed with 18–22 forming stations, the machine is equipped with Grade 416 stainless steel forming rolls and Grade 303 stainless steel shafts measuring 1½” to 2″ in diameter. It operates on 220V 3-phase electric-hydraulic power and includes a hydraulically powered rear profile shear.

A digital control system enables full automation, supporting production speeds of 80–100 feet per minute. The machine stand is included as standard. A non-powered 48″ x 5000 lb decoiler is available as a separate accessory.

| Series | Details | Parameter |

|---|---|---|

| Product Sheet | Raw material | PPGI |

| Thickness | 22–28 gauge | |

| Cutting length | Adjustable | |

| Decoiler | Type | Manual core expansion |

| Capacity | 5 tons | |

| Coil ID | 450–550 mm | |

| Max width | 1250 mm | |

| Main Roll Former | Shaft | Ø90 mm, 45# steel |

| Rollers | 45# steel, chromed | |

| Stations | 20 | |

| Speed | 0–30 m/min | |

| Power | 7.5 kW servo motor | |

| Transmission | Gear box + chains | |

| PLC Control | PLC/Screen | Delta, touch screen |

| Electrical parts | Schneider, Omron counter | |

| Hydraulic Sys. | Cutting type | Hydraulic stop cut |

| Motor power | 5.5 kW | |

| Oil | #46, 100–120 L | |

| Tolerance | ±2 mm/10 m | |

| Receiving Table | Size | 3m × 2 pcs |

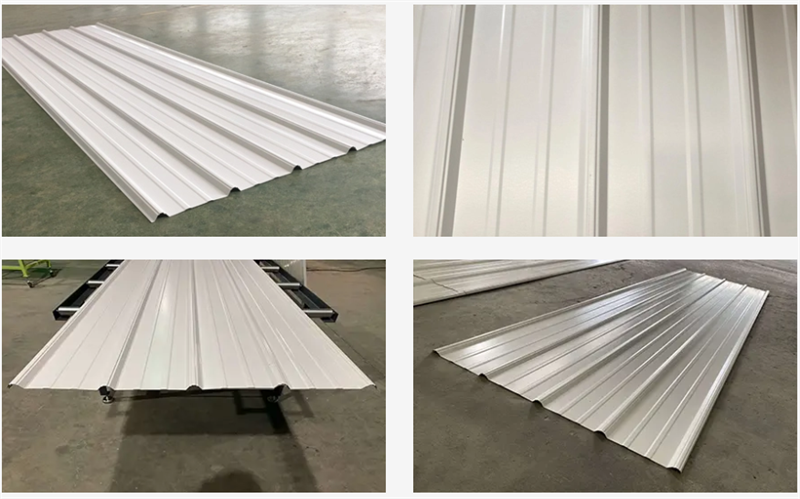

AG Panel Roofing Applications

AG Panels deliver a robust, weatherproof, and economical roofing option, perfect for both home and farm use.

-

Deliver reliable defense against extreme climate exposure.

-

Lower upkeep expenses and enhance roof durability.

-

Excellent for installation over current shingle roofs, minimizing effort, time, and waste removal fees.

-

Engineered with pronounced ribs for enhanced visual appeal and exceptional functionality in roofing and siding uses.

Reviews

There are no reviews yet.