AG Roof Panel Roll Forming Machine ZTFRM Roof Panel Production Line

High-Performance Metal Roof Making Machine for Agricultural & Industrial Projects

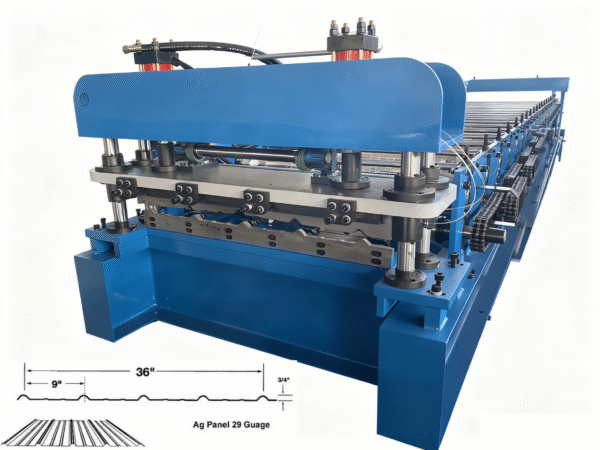

The Zhongtuo AG Roof Panel Roll Forming Machine is a fully automatic machine designed for high-speed production of AG metal roof panels. Engineered with precision rollers, a heavy-duty motor, and a computerized control system, this machine ensures reliable operation and consistent panel quality for roofing manufacturers worldwide.

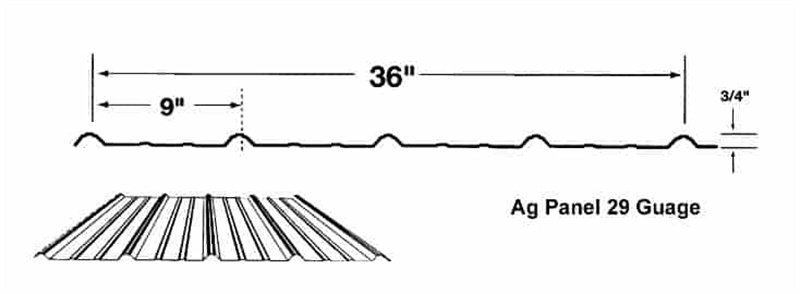

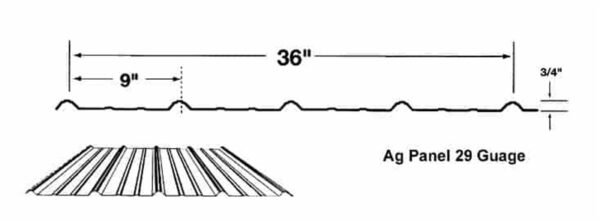

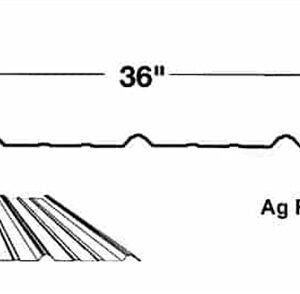

AG Panel Metal Roof Profile

The AG metal roof panel—short for Agricultural Panel—is one of the most versatile and durable roofing solutions on the market. Its corrugated rib design enhances strength and promotes excellent water drainage.

All Zhongtuo Machines are fully assembled and tested at our Cangzhou factory, backed by a 1-year warranty for parts and labor. Each unit can be customized according to customer profile requirements, ensuring seamless integration into any production environment.

AG Roof Panel Roll Forming Machine Specifications

| Item | Details |

|---|---|

| Brand | Zhongtuo / ZTFRM |

| Machine Dimensions | 40 ft (L) × 5 ft (W) |

| Material Thickness | 24 – 29 gauge steel or aluminum |

| Forming Stations | 18 heavy-duty roller stands |

| Motor Power | Industrial-grade heavy motor |

| Drive System | Chain drive system |

| Shearing Type | Pre-shear cutting |

| Control | Computerized batching, read-out in inches |

| Safety System | E-stops & full protective covers |

| Uncoiler | 10,000 lb hydraulic uncoiler with coil car |

ZTFRM AG Roof Panel Forming Line — Working Process

- Material Loading: The steel or aluminum coil is placed on the 10,000 lb uncoiler.

- Uncoiling: The coil car feeds material smoothly into the forming section.

- Roll Forming: The strip passes through 18 precision roller stands, forming the AG roof profile.

- Cutting: The pre-shear system cuts panels to exact length under computerized batching control.

- Output: Finished panels are discharged automatically, ready for stacking or packaging.

The Zhongtuo AG Roof Panel Machine combines strength, precision, and efficiency, making it ideal for metal roofing panel production lines in agricultural, commercial, and residential construction projects.

Key Features:

- Made from galvanized or coated steel for corrosion resistance.

- Standard width around 36 inches; custom lengths available.

- Easy installation with overlapping ribs for watertight sealing.

- Long lifespan with minimal maintenance.

- Available in various colors and finishes for architectural flexibility.

Applications: Agricultural buildings, factories, warehouses, barns, workshops, and commercial roofing systems.

Why Choose Zhongtuo & ZTFRM Machines

- Expert Engineering: Built by Zhongtuo, a trusted manufacturer specializing in roll forming technology.

- Heavy-Duty Design: Robust frame and rollers for 24/7 industrial operation.

- User-Friendly Control: Computerized batching and real-time data readout in inches.

- Full Service: Global installation, training, and after-sales support.

- Customization: Tailored profiles and optional add-ons available for every roofing project.

Whether you need a metal roof panel making machine, AG panel roll forming line, or custom roofing sheet forming equipment, Zhongtuo Machine and ZTFRM provide reliable, high-performance solutions trusted worldwide.

Reviews

There are no reviews yet.