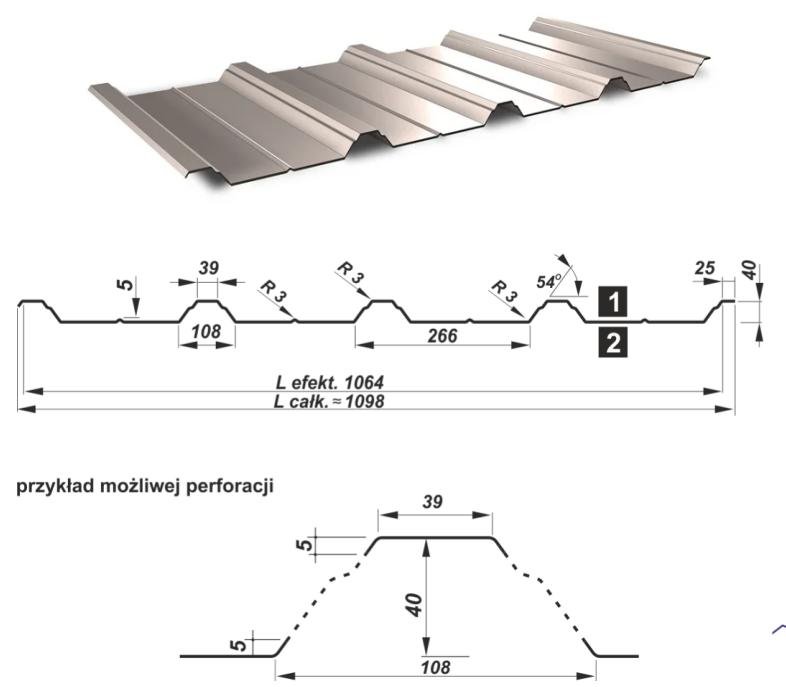

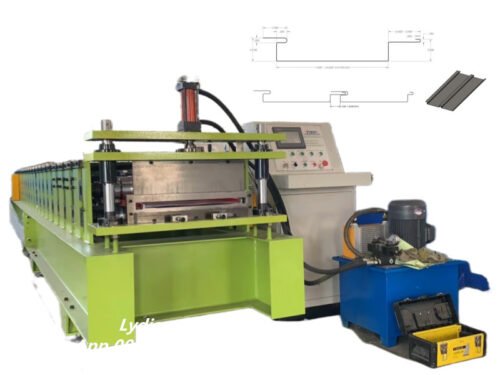

T35 T40 Trapezoidal Profile Roof Sheet Roll Forming Machine for High-Quality Roofing Panels

This roof sheet roll forming machine is designed for producing T35 trapezoidal roof panels and similar profiles. The T35 trapezoidal metal sheet, thanks to its wide range of applications, has become a popular product in investment construction and individual projects. In particular, it is often applied as roofing and wall cladding in gas stations, silos, heating boiler casings, facades, warehouses, and production halls.

The line processes PPGI/GI steel coils, thickness 0.4–1.2 mm, with feeding width 1000 mm or 1250 mm. It integrates a 15T hydraulic decoiler with loading car, 27-station roll former, non-stop fly shearing system, and 12 m automatic stacker, which together ensure high efficiency, precision, and durability

Applications of T35 Trapezoidal Sheet:

-

Gas station designs

-

Silo casing

-

Heating boiler casing

-

Facade and roofing

-

Warehouses and production halls

The T40 trapezoidal profile roof sheet is another popular choice. With a wave height of 40 mm, it is widely used for industrial facilities, logistics centers, and residential buildings. Thanks to its durability and excellent load-bearing capacity, T40 trapezoidal sheet roofing is highly appreciated by architects and contractors.

Applications of T40 Trapezoidal Sheet:

-

Large-span industrial buildings

-

Residential roofs

-

Facade cladding for modern architecture

-

Warehouses and logistic hubs

Line Components and Features

-

15T Hydraulic Decoiler with Loading Car – expandable mandrel, brake system, ground sensor.

-

Main Roll Former – 27 stations with 90 mm shafts, robust 400# H frame with diagonal bracing for stability.

-

PLC Control System – Siemens PLC, multilingual touch screen (EN/FR/CN/AR), Schneider low voltage.

-

Hydraulic Fly Shearing – pillar-type cylinder, GB-Cr12 blades, energy accumulator, oil cooler.

-

Automatic Stacker – pneumatic arms, cylinder push system, chain-driven conveyor, forklift-friendly.

-

Spare Parts – wheels, valves, seals, bearings, rollers, PLC, encoders.

Technical Advantages of T35 & T40 Roof Sheets

-

Produced according to EN 14782:2008 standards and CE marked for EU construction projects

-

UV-resistant paint coating (25 microns) with a 10-year warranty

-

State-of-the-art Finnish production technology ensures precision and consistency

-

Optional anti-condensation felt can be applied under the steel

-

Lightweight design (approx. 5 kg/m²), reducing roof structure load compared to traditional clay tiles

-

Technical Specification (Quick Table)

Parameter Specification Product type T35 trapezoidal roof sheet / roof panel Material PPGI / GI (pre-painted galvanized steel) Material thickness 0.4 – 1.2 mm Feeding width 1000 mm / 1250 mm Roll forming stations 27 stations (incl. rubber feeding shafts) Rolling shaft material / diameter 45# steel, Ø90 mm, hardened/chrome plated Rollers 45# steel, chrome plated (Cr thickness 0.05 mm) Transmission Gearbox transmission with bevel gears, interlinked chains Work speed 0 – 35 m/min (adjustable) Decoiler capacity 15 T (hydraulic), max coil width 1250 mm Main drive power 15 kW + 15 kW Cutting system Non-stop fly tracking shearing, GB-Cr12 blades Cutting accuracy ±2 mm Stacker 12 m auto stacker, stack height ≤300 mm Control system Siemens PLC & HMI, Schneider electricals, Omron counter Warranty 1 year; lifetime technical support

Reviews

There are no reviews yet.