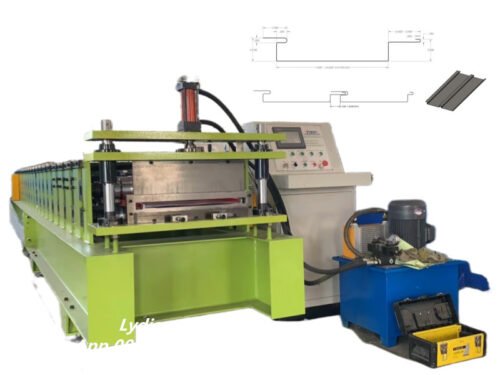

Overview of Double Layer Corrugated & Qtile Metal Roof Tile Sheet Roll Forming Machine

The Automatic 1025 Corrugated and Glazed Step Tile Double Layer Metal Roofing Roll Forming Machine is designed for producing two profiles on a single frame — corrugated roof panels and glazed step tiles.

This double-layer roll-forming machine ensures high efficiency, precision forming, and durability, making it perfect for roof and wall panel applications in industrial, commercial, and residential projects.

Technical Specifications of 1035 Glazed Q Tile Roofing Sheet Making Machine

| Model No. | Double Roll Forming Machine |

|---|---|

| Tile Type | Corrugated & Glazed Steel |

| Certification | CE / ISO |

| Condition | Brand New |

| Customized | Available |

| Usage | Roof / Wall |

| Transmission Method | Hydraulic Pressure |

| Production Speed | 12 m/min |

| Material Thickness | 0.3–0.8 mm / 0.8–1.5 mm |

| Shaft Diameter | 70 / 80 mm |

| Main Frame | 350H / 400H / 500H |

| Motor Power | 9 kW |

| Weight | 5–8 tons |

| Dimension | 10000 × 7500 × 1200 mm |

| Voltage | 380V / 3Phase / 50Hz |

| Roller Material | 45# High-Grade Forged Steel, Hard Chrome Plated |

| Cutting Blade | Cr12 Mould Steel with Heat Treatment |

| Operators Required | 1–2 Workers |

Key Features of RollForming Machine

- Two profiles in one machine (corrugated + glazed)

- Hydraulic cutting for smooth, precise results

- PLC control system (Schneider / Siemens)

- Stable operation with low maintenance

- Compact design and high efficiency

Production Flow of Metal Roof Tile Sheet Roll Forming Machine

Decoiler → Feeding → Roll Forming → Hydraulic Cutting → PLC Control → Receiving Table

Technical Data

- Drive Mode: Chain / Gear / Gearbox

- Roller Material: 45# Steel / Bearing Steel

- Forming Stations: 25+ (customized)

- Hydraulic Power: 3–5 kW

- Motor Power: 9.5 kW

- PLC: Touch Screen Intelligent Control

- Production Speed: 0–12 m/min

- Color: Customizable

Machine Components

| Part | Quantity | Type |

|---|---|---|

| Decoiler System | 1 | Manual / Hydraulic |

| Main Roll Forming Unit | 1 | Split / Integral |

| Hydraulic Shearing System | 1 | Electric / Hydraulic |

| Receiving Table | 1 | Simple / Automatic Stacker |

| Hydraulic Station | 1 | Latest Edition |

| PLC Control System | 1 | Automatic with Touch Screen |

Detailed Components of Roll Forming Machine

A. Decoiler System

- Coil Width: 1250 / 1450 mm

- Coil Inner Diameter: 450–550 mm

- Capacity: 5T / 10T

- Optional loading car available

B. Feeding & Guiding System

- Rubber rollers and guide chains for stable feeding

- Manual broach and pressure wheels to save material

C. Roll Forming Frame

- Heavy-duty welded H-beam structure

- Gearbox or chain-driven system

- 25+ forming steps for accurate shaping

D. Hydraulic Cutting System

- Cr12 steel blades with heat treatment

- Hydraulic drive for precision cutting

- Reliable performance in all climates

E. Receiving Table

- Simple or automatic stacking system optional

- Space-saving and efficient design

Certifications

✅ CE Certified

✅ ISO9001 Quality Management

✅ European Safety Standards

Reviews

There are no reviews yet.