The Barrel Corrugation Machine is designed to process ultra-thin coils with a thickness range of 0.17 to 0.30 mm. Unlike conventional longitudinal forming machines, this corrugator adopts transverse forming. This unique design can produce corrugated sheets with a width of 3 to 6 meters, which is very suitable for wide metal panels.

Technical Specifications Table of Barrel Corrugated Sheet Rolling Machine

| Specification | Details |

| 1.1 Feeding width | ≤1250mm |

| 1.2 Length of the sheet | 5000mm |

| 1.3 Coil material | Galvanized sheet |

| 1.4 Material thickness | 0.13mm – 0.50mm |

| 2.1 Roller station | 2 sets (4 pieces) |

| 2.2 Roller diameter | 450mm, Material: 45# steel |

| 2.3 Speed | 2-3 seconds per piece |

| 2.4 Size | 4000mm × 1800mm × 1400mm |

| 2.5 Weight | 12 T |

| 2.6 Voltage | 380v, 50Hz, 3 Phase |

| 2.7 Motor | 7.5 kW |

| 2.8 Feeding platform width | 1 meter |

| 2.9 Crest height | Adjustable in a limited range |

| 3.0 Feeding platform moving distance | 750-1200 mm |

| 3.1 Control type | Electric control with buttons for forward/backward and speed adjustment |

| 3.2 Roller distance adjustment | Manual via hand wheel, synchronized on both sides |

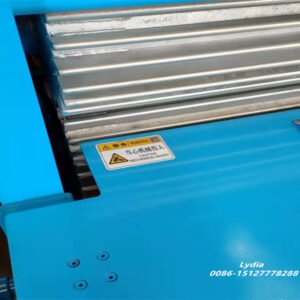

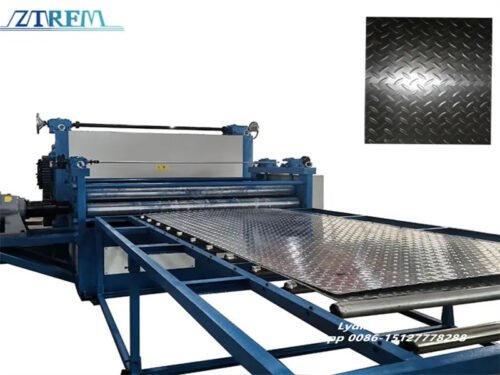

The pictures of the machine barrel corrugated roofing sheet rolling machine

Jasmine –

good machines