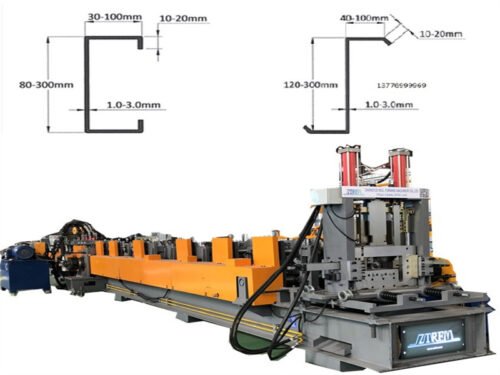

High-Strength Eave Strut Roll Forming MachineAutomatic Size-Change & Stacking System

Our High-Strength Eave Strut Roll Forming Machine is specially designed according to the customer-confirmed profile drawings and production requirements. This production line is suitable for manufacturing C-shaped eave struts made from high-strength galvanized steel, widely used in pre-engineered steel buildings, warehouses, and industrial structures.

The machine supports S350GD to S550GD high-strength steel, with tensile strengths ranging from 630 to 790 MPa and material thicknesses from 2 to 3 mm. The inner bending radius is precisely controlled at R3, ensuring excellent profile consistency and structural performance.

Production Process Flow

Decoiling → Feeding & Leveling → Punching → Pre-Cutting → Roll Forming → Automatic Stacking

The entire line is controlled by one central PLC system, enabling automatic operation, stable production, and repeatable accuracy.

Raw Material Specification

| Item | Specification |

|---|---|

| Material | High-strength galvanized steel |

| Grade | S350GD – S550GD |

| Tensile Strength | 630–790 MPa |

| Thickness | 2–3 mm |

| Inner Radius | R3 |

1. 5-Ton Double-Head Hydraulic Decoiler with Coil Car

The decoiling system is designed for heavy-duty coils and smooth feeding into the forming line.

| Parameter | Specification |

|---|---|

| Load Capacity | 5 tons |

| Coil Inner Diameter | 508–610 mm |

| Max Coil Outer Diameter | 1600 mm |

| Max Coil Width | 400 mm |

| Coil Car Type | Scissor-lift trolley |

| Motor Power | 5.5 kW |

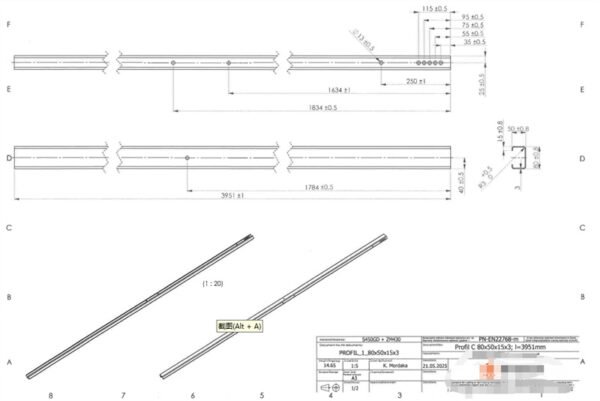

2. Feeding, Leveling, Punching & Cutting Unit

This integrated section ensures flat material, accurate hole positioning, and precise cutting before roll forming.

| Item | Specification |

|---|---|

| Leveling Structure | 3 upper + 4 lower rollers |

| Leveling Shaft Diameter | 110 mm |

| Punching Stations | 5 stations |

| Punching Dies | 3 complete die sets |

| Cutting Method | Hydraulic pre-cutting |

| Hydraulic Power | 15 kW |

Punching patterns strictly follow the customer-approved drawings, guaranteeing perfect compatibility with steel building connections.

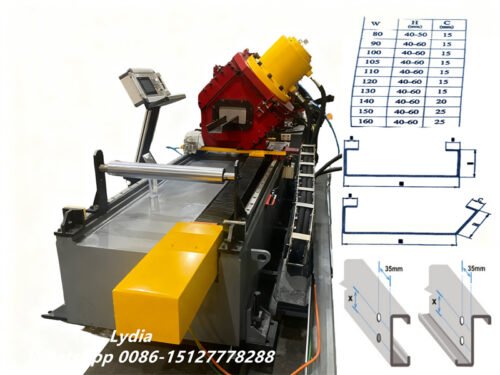

3. Roll Forming Section

The forming system is built for high-strength material and long-term stable operation.

| Item | Specification |

|---|---|

| Forming Stations | 16 stations + side rollers |

| Roller Material | D2 steel, hardness 58–60 HRC |

| Shaft Material | 40Cr steel, heat-treated |

| Main Motor | 30 kW servo motor |

| Drive System | Precision gear transmission |

| Size Change | PLC automatic adjustment |

| Size Range | 100 / 105 / 110 / 115 / 120 / 125 |

| Angle Adjustment | Manual |

| Power Supply | 380V / 60Hz / 3 Phase |

The servo-driven system ensures stable forming even when processing high-strength steel up to 3 mm thick.

4. Advanced Control System

A single main control cabinet manages the entire production line, enhancing operational efficiency and minimizing human error.

| Feature | Description |

|---|---|

| Control System | PLC + Inverter (Mitsubishi) |

| Upper Computer | Industrial PC with data storage |

| Data Management | Production data can be saved |

| Cabinet Branding | ZHONGTUO company information |

| Password Protection | Activated after 6 months (with warranty deposit) |

| Language Options | Chinese / English / Polish |

5. 12-Meter Automatic Stacking System

The automatic stacking unit improves productivity and ensures neat material handling after forming.

| Item | Specification |

|---|---|

| Stacking Length | 1.5 – 12 meters |

| Profile Compatibility | Supports two different shapes |

| Stacking Height | As per the confirmed layout drawing |

| Machine Color | Customizable (color code to be confirmed) |

Production Speed Requirement

- 15 seconds per piece

- 30 seconds per piece

Speed can be adjusted based on product length and punching requirements.

Why Choose This Eave Strut Roll Forming Machine

- Designed for high-strength steel S350GD–S550GD

- Fully automatic size change via PLC

- Stable performance for 2–3 mm thick material

- Accurate punching and cutting

- Servo motor + precision gear transmission

- Multi-language control system

- Integrated automatic stacking solution

Reviews

There are no reviews yet.