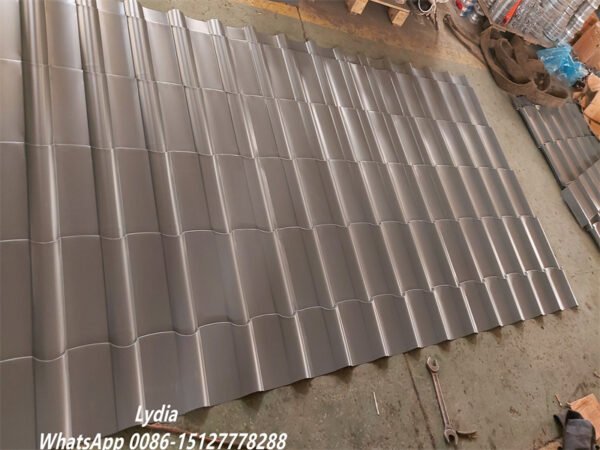

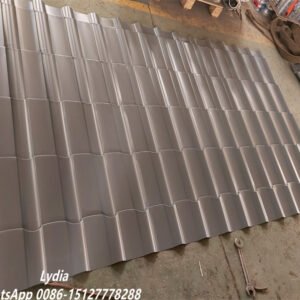

Glazed Roof Tile Double Layer Roof Sheet Roll Forming Machine

The Glazed Roof Tile Double Layer Roof Sheet Roll Forming Machine is designed for producing two types of metal roofing sheets, 2 pieces of glazed step tiles on one machine.

It features automatic control, high efficiency, and long service life, making it ideal for metal roofing sheet production in residential, commercial, and industrial buildings.

Our machine offers simple operation, stable performance, and lifetime online after-sales service.

A professional technical team ensures smooth installation, training, and maintenance support, making your purchase safe and worry-free.

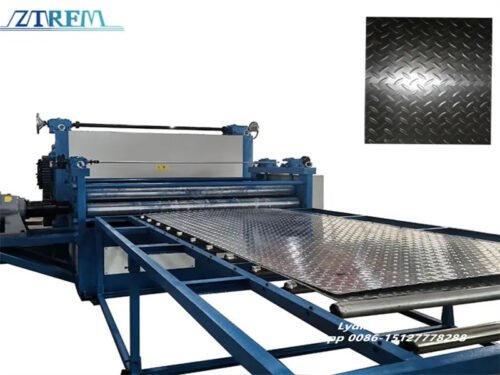

Technical Parameters of Double Layer Roof Sheet Roll Forming Machine

| Item | Specification |

|---|---|

| Product Name | Double Deck Roofing Sheet Roll Forming Machine |

| Base Material | GI, GL, PPGI, PPGL, Aluminum |

| Thickness | 0.3mm–0.8mm (customizable) |

| Effective Width | 762 + 686mm (customizable) |

| Machine Size | 6050 × 1500 × 1600mm |

| Machine Weight | 5.5 Tons |

| Frame Material | 350H Steel (customizable) |

| Side Panel Thickness | 16mm (customizable) |

| Color | Standard international color or customized |

| Rollers | Upper: 13 / Lower: 18 |

| Roller Material | 45# Steel, Cr12Mov, HRC 58–62 |

| Shaft Diameter | Φ70mm |

| Drive Mode | Chain wheel and cycle chain (1 inch) |

| Production Speed | 10–15 m/min |

| Voltage | 380V 50Hz 3-phase (customizable) |

| Motor Power | 5.5KW |

| Hydraulic Pump Station | 4KW (Brand: LI CHAO, customizable) |

| Cutting Type | Double guide pillar hydraulic cutting |

| Cutting Blade | Cr12Mov, HRC 58–62 |

| Control System | PLC electronic control cabinet |

| Screen / Operation | Button control with multiple languages |

| Features | Famous brand components, multi-purpose, fully automatic computer control, easy operation, long service life |

Main Components

1. Feeding Table

- Function: Guides sheet material into the machine.

- Benefits: Keeps the sheet smooth and flat.

- Extra: Hand knife design saves raw material.

2. Main Rollers

- Material: 45# high carbon steel.

- Process: Forged, polished, heat-treated, and chrome-plated.

- Feature: Smooth and hard surface — does not scratch color-coated steel sheets.

3. Computer Control Cabinet

- Brand options: LICHAO, DELTA, SIEMENS (based on customer requirement).

- Operation language: English, Russian, Spanish, or Chinese.

- Function: Ensures accurate cutting length and automatic production control.

4. Hydraulic Station

- Power: 4KW high-efficiency hydraulic system.

- Function: Provides stable pressure and precise cutting performance.

5. Cutting Head

- Blade Material: Cr12Mov, laser-cut, 16mm thickness

- Structure: Double guide post + hydraulic drive.

- Guide Post: 45# steel, quenched before heat treatment to ensure surface hardness and smooth operation.

Advantages of the Machine

Dual Function: Produces both corrugated and glazed step tiles on one machine.

Automatic Control: PLC system with multiple language options.

High Precision: Laser cutting and high-strength rollers ensure quality.

Durable Structure: 350H steel frame and chrome-plated rollers.

Easy Operation: Simple setup and user-friendly control system.

Lifetime After-Sales Support: Online guidance and parts supply available worldwide.

Reviews

There are no reviews yet.