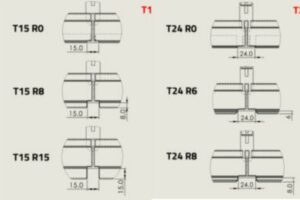

The T-bar is a specialized profile designed to support suspended ceiling tiles, commonly used in T-grid ceiling systems. Standard panel sizes include 60 cm x 60 cm and 60 cm x 120 cm. This system typically consists of three types of profiles: 600 mm and 1200 mm cross tees, and a 3600 mm main runner. However, other dimensions—such as those used in Imperial systems—are also available on the market.

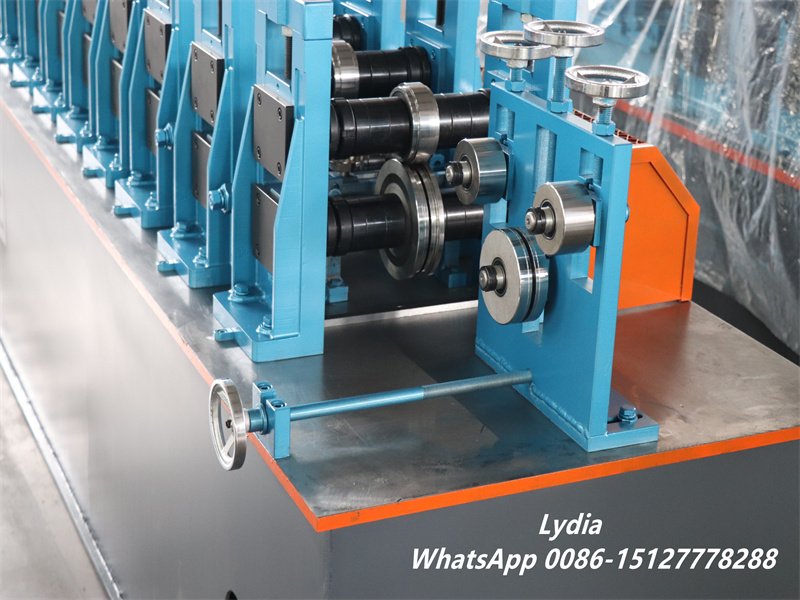

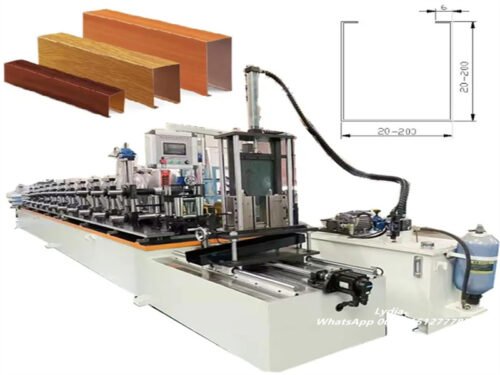

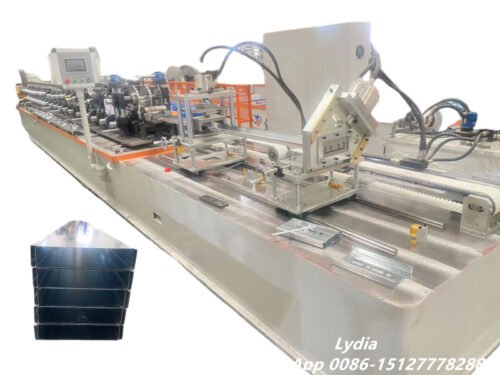

The fully automatic ceiling T-bar roll forming machine is specifically engineered for producing standard 24 mm main T-bars used in suspended ceiling grids. It is a highly popular machine in the Cangzhou region. T-bars are typically made from material with a thickness ranging from 0.3 mm to 1.2 mm and are available in lengths between 3000 mm and 6000 mm.

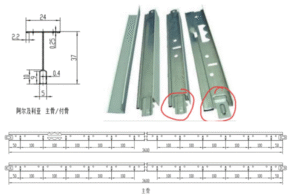

Structurally, T-bars feature a characteristic “T”-shaped cross-section, with the upper flange typically measuring 24 mm in width and the lower flange around 38 mm. Widely used in architectural ceiling systems, T-bars are known for their excellent structural stability. The unique “T” profile ensures reliable support and secure installation within the suspended ceiling framework.

The Profile Drawing:

Parameters of Full automatic ceiling t bar roll former suspended ceiling grid machine, Main T bar(24mm standard) making machine.

| ZTRFM Ceiling T grid Machine | ||

| 1.Formed Material | GI | Thickness:0.15-0.4mm |

| 2.Decoiler | Hydraulic automatic decoiler | Manual decoiler(will give you as free) |

| 3.Main body | Roller station | 18 rows for the main T

16 roller station for the cross T bar |

| Diameter of shaft | 50 mm solid shaft | |

| Material of rollers | 45# steel, hard chrome plated on the surface | |

| Machine body frame | Metal steel welded | |

| Drive | Gearbox transmission | |

| Dimension(L*W*H) | 5500*800*1200(customize) | |

| Weight | About 6T | |

| 4.Cutter | Automatic | cr12mov material, no scratches, no deformation |

| 5.Power | Motor Power | 7.5KW*2 sets |

| Hydraulic system power | 7.5KW | |

| 6.Voltage | 380V 50Hz 3Phase | As your requirement |

| 7.Control system | Electric Box | Customized(famous brand) |

| Language | English(Support multiple languages) | |

| PLC | Automatic production of the whole machine. Can set batch, length, quantity, etc. | |

| 18.Forming Speed | Max 35m/min(customized) | Speed is adjustable according to customer’s request |

With extensive experience in metal suspended ceilings—including expanded metal, honeycomb, baffle, vector, linear panel systems, and T-carrier systems (T24, T15)—Zhongtuo offers innovative solutions tailored to meet the needs of modern architecture.

Zhongtuo suspended ceiling systems are designed not only to conceal ceiling infrastructure but also to facilitate the seamless integration of lighting, ventilation, and fire protection components. At the same time, they deliver excellent acoustic performance, aligning with the demands of contemporary interior design.

Metal suspended ceiling panels, made from aluminum or steel, are installed on T-24 or T-15 carrier systems using a tool-free snap-in method. These panels may feature a variety of perforation patterns and are produced with an 8 mm recess to enhance visual depth. With multiple sizes, perforation options, panel types, and edge styles available, the system offers both functionality and aesthetic appeal—making it ideal for environments where easy installation, access, and visual harmony are essential.

More Pictures of Machines

Reviews

There are no reviews yet.