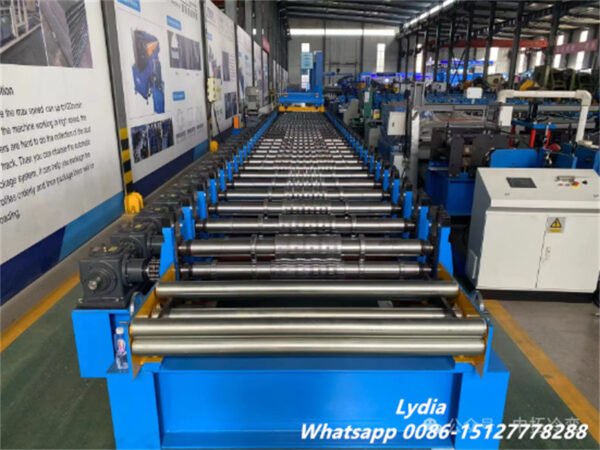

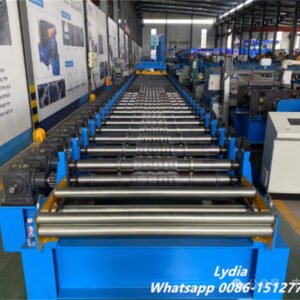

The corrugated metal roofing sheet machine, specifically designed for arch roof panel production, features a distinctive single-side single-guide-post cutting structure. This design provides multiple operational advantages:

High Accuracy: The guide post ensures that the cutting blade maintains a precise trajectory during movement. This minimizes dimensional error to within millimeters, guaranteeing that each panel’s curvature and edge are consistent with design standards.

Long Service Life: The guide post is highly durable and wear-resistant. With integrated lubrication, wear during extended operation is significantly reduced. Compared to conventional machines, core components offer a longer lifespan.

Efficiency: Though the guide post structure may increase initial equipment investment due to higher material and machining requirements, the return is realized in operation. Panels are positioned and cut within seconds, reducing setup time and material waste.

This combination of “high precision, long lifespan, and fast positioning” makes the single-guide-post structure ideal for processing complex roofing panel shapes in industrial applications.

Servo-Tracking Shearing for High-Speed Production

The arch roof panel machine employs servo-tracking cutting technology, which allows the main forming unit to run continuously while the cutter synchronizes its movement with the steel sheet. This dynamic tracking mechanism dramatically improves efficiency.

Cutting Speed: 25–40 meters per minute

Application: Perfect for large-scale operations with high-volume demands

Benefits: Shortened production cycles, increased output, lower unit costs

Its fast and consistent performance makes it the perfect choice for manufacturers looking to meet tight production deadlines without compromising on quality.

The machine adopts a modular segmented forming process, dividing the panel forming into multiple coordinated stages:

- Primary Forming: Applies basic curvature using segmented pressure rollers.

- Edge Shaping: Precision knives trim the panel edges to eliminate burrs and ensure clean finishes.

- Surface Flattening: Polished rollers “iron out” fine wrinkles and surface textures, delivering a mirror-smooth appearance

Each module is individually adjustable in terms of pressure, temperature, and trajectory. This modular “custom-forming” approach ensures that finished panels are uniform in curvature, accurate in dimension, and flawless in surface quality, suitable for both classical domes and modern villa rooftops.

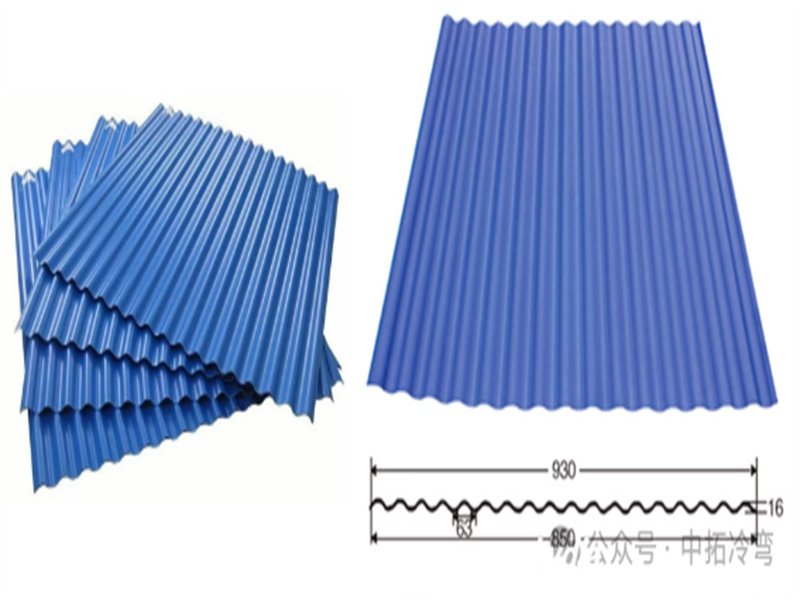

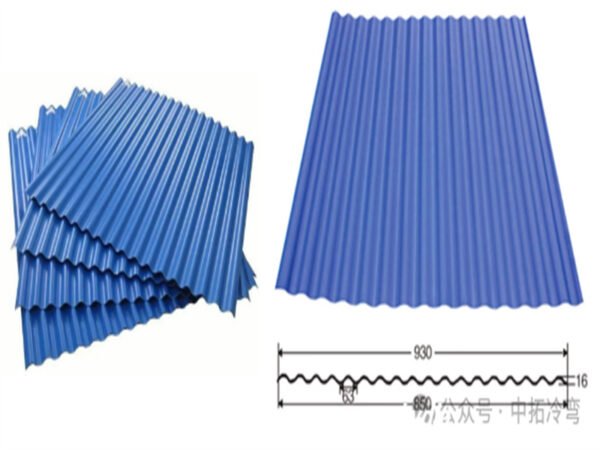

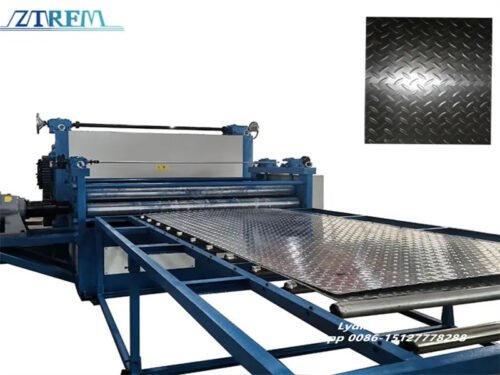

Standardized Panel Specifications for Broad Application

The arch roofing panels produced by this machine adhere to industry-standard dimensions:

Wave Width: \~63 mm

Suitable for various roof types, including sloped roofs and curved domes.

Panel Thickness: 0.3 mm to 0.8 mm

0.3–0.5 mm: Ideal for lightweight structures like gazebos and temporary shelters

0.8 mm: Perfect for high-strength applications such as coastal buildings or industrial plants requiring strong wind and rain resistance

The machine’s adjustable roller system allows precise control over thickness and wave width, accommodating different materials like galvanized steel and pre-painted sheets.

Reviews

There are no reviews yet.