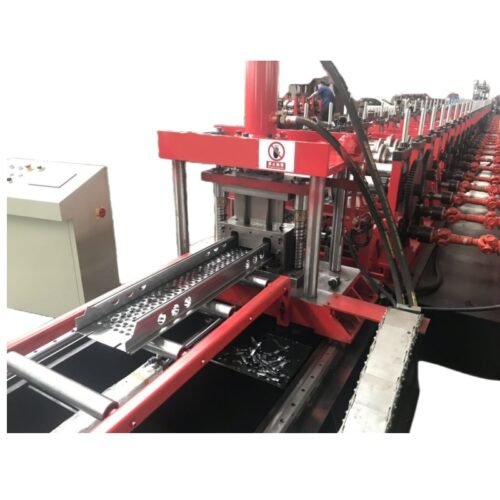

Shelf Panel Roll Forming Machine – High-Precision Storage & Supermarket Shelf Production Line by ZTRFM

ZTRFM offers a fully automated Shelf Panel Roll Forming Machine designed for manufacturing supermarket shelves, warehouse rack panels, and customized storage profiles. As a leading roll forming solution provider in China, ZTRFM integrates advanced engineering, high-quality components, and stable production performance into every piece of equipment.

With decades of manufacturing experience, ZTRFM ensures reliable machine operation, excellent durability, and strong support for large-volume industrial production.

Overview of ZTRFM Shelf Panel Roll Forming Machine

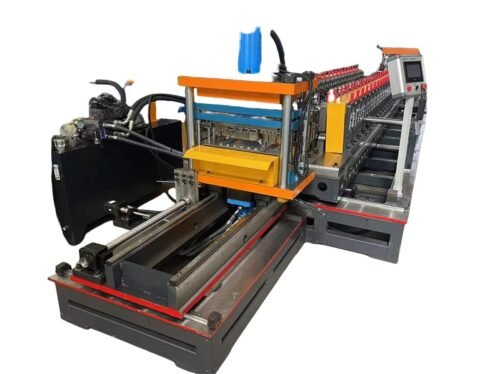

The ZTRFM shelf panel forming line is engineered to produce adjustable-width panels through a servo-controlled system. Operators can switch profile widths in approximately 10 minutes, greatly improving flexibility and reducing downtime during format changes.

Built with a robust machine frame, high-hardness CR12MOV rollers, premium-grade motors, and 30mm-thick archway stands, the equipment maintains long-term precision even under continuous operation.

Complete Shelf System Manufacturing Line

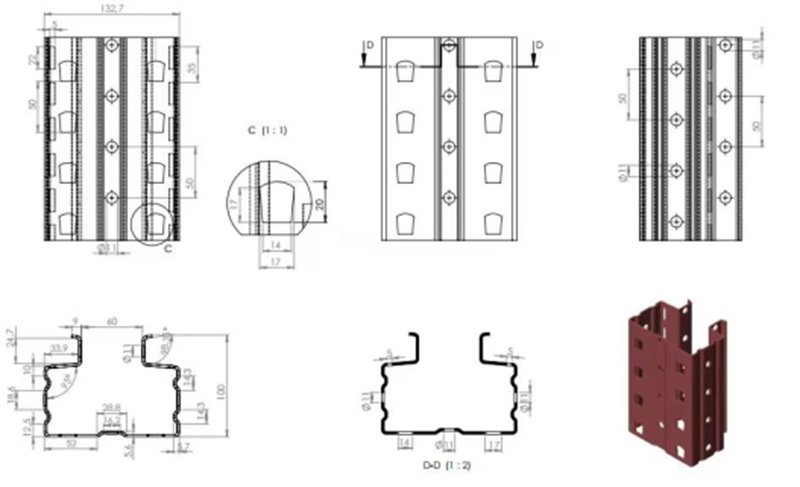

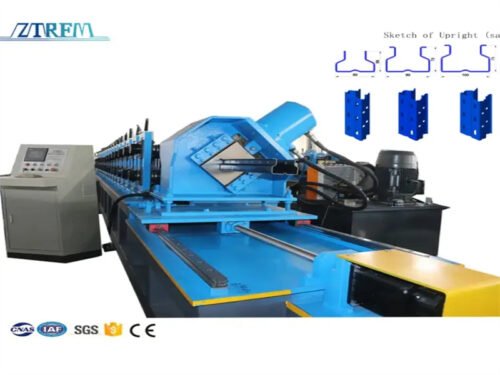

ZTRFM provides not only the shelf panel roll forming machine but also a full range of equipment for producing a complete racking and shelving system, including:

- Shelf upright/column forming machine

- Shelf laminate forming equipment

- Shelf beam and step-beam (P-beam) production lines

- Shelf reinforcement profile forming machine

- Shelf label channel roll forming line

- Universal angle steel forming equipment

- Shelf bullet beam forming line

This allows customers to build a full production system for warehouse racking and supermarket shelving.

Technical Specifications of Metal Shelf Panel Production Line

| Item | Specification |

|---|---|

| Raw Materials | GI steel strip / Stainless steel |

| Profile Size | Customized according to drawings |

| Max Speed | 30 m/min |

| Roll Forming Stations | 20–125 stations (depending on profile) |

| Total Power | Approx. 35 kW |

Main Components of the Production Line

The ZTRFM shelf panel line typically includes:

- Hydraulic decoiler

- Leveling & straightening section

- Servo feeder

- High-speed punching unit

- Precision roll forming machine

- Hydraulic cutting & bending system

- Output table

- PLC electric control cabinet

Production Process Flow:

Decoiling → Leveling → Servo Feeding → Punching → Dual-side Roll Forming → Hydraulic Cutting → Receiving Table → Optional Welding

This coordinated workflow ensures stable performance and high productivity.

Key Features of ZTRFM Shelf Panel Roll Forming Machine

- PLC Intelligent Control – Achieves fully automated operation, high safety, and efficient production management.

- High-Strength Frame Structure – The forming base is manufactured from thickened channel steel, ensuring long-term stability.

- Durable Shaft Material – Roll shafts are made from 40Cr steel and treated with quenching and tempering to reach HB280 hardness.

- High-Quality Rollers – GCr15 roller material, heat-treated to HRC 56–62, ensures excellent forming accuracy and extended service life.

- Reliable Transmission System – Gearbox or chain transmission designed to match factory production requirements.

More Details About the Shelf Panel Line

The ZTRFM machine integrates decoiling, straightening, punching, roll forming, and cutting into a synchronized system. Customers report smooth machine performance, stable forming quality, and easy daily operation. The equipment is also designed with maintenance convenience in mind, helping reduce long-term operating costs.

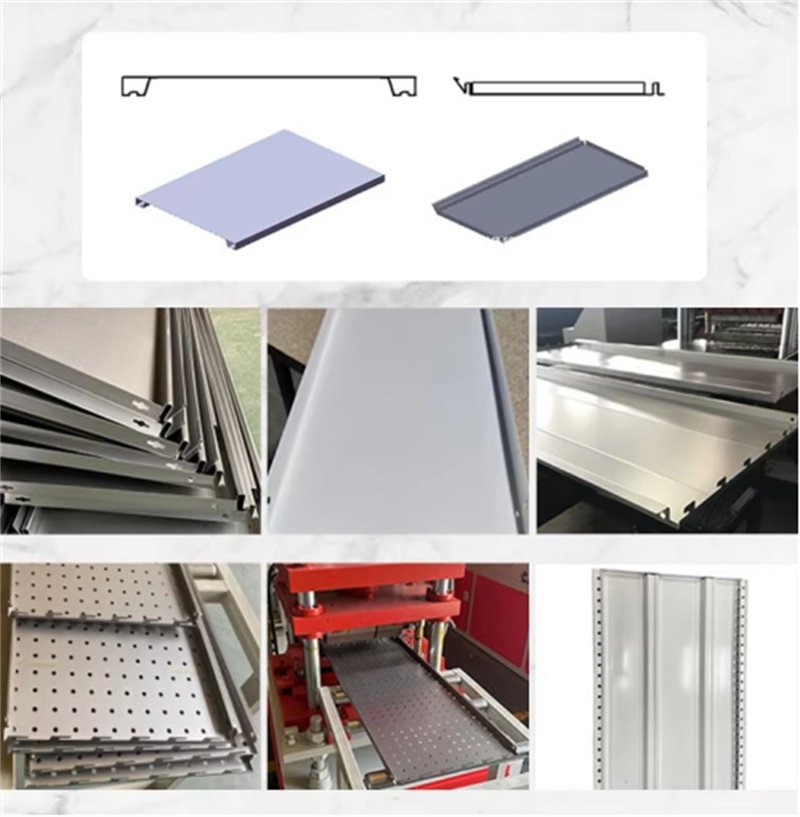

ZTRFM shelf panel machines can manufacture various supermarket and storage shelf panel types. With customized design services, ZTRFM engineers can develop machines based on customer drawings, ensuring that both standard and non-standard shelf designs are precisely produced.

Whether you need supermarket shelves, warehouse deck panels, heavy-duty storage shelves, or customized display panels, ZTRFM provides tailored roll forming machine solutions. Simply provide your technical drawings or profile samples—ZTRFM will deliver a machine designed precisely for your production requirements.

Reviews

There are no reviews yet.