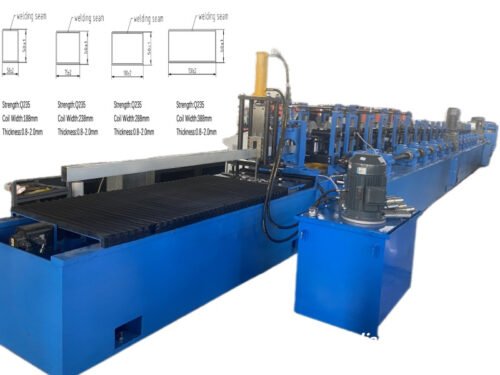

Tube Roll Forming Machine Locked Tube Roll Forming Machine

The Tube Roll Forming Machine is designed for producing precision metal tubes and pipes from aluminum or painted steel coils. It adopts a continuous roll forming process to ensure stable production, high accuracy, and smooth surface finish. Widely used in construction, guttering, HVAC, and industrial manufacturing, this machine combines durability with advanced automation for efficient tube production.

Technical Specifications of Tube Mill & Pipe Mill Roll Forming Machine

| Item | Specification |

|---|---|

| Production Capacity | 60 ft/min |

| Condition | New |

| Pipe Thickness | 0.5 mm – 0.8 mm (0.27″ – 0.32″) |

| Pipe Diameter | 203 mm × 51 mm (8″ × 2″) |

| Applicable Materials | Aluminum, Painted Steel |

| Applicable Industries | Manufacturing, Guttering, HVAC |

| Machine Dimensions (L×W×H) | 30′ × 5′ × 5′ |

| Machine Weight | 7 Tons |

| Warranty | 1 Year (Parts & Labor) |

| Factory Location | Orlando, Florida, USA |

Key Features & Advantages of HF welding pipe mill

- High Efficiency – The machine ensures continuous and stable production, maintaining consistent tube quality even during long operation hours. This makes it ideal for large-scale manufacturing lines requiring both speed and reliability.

- Precision Forming – Equipped with CNC-machined rollers, each forming step is precisely controlled, ensuring accurate dimensions and perfectly smooth surfaces throughout the entire production process. As a result, every tube meets strict quality standards.

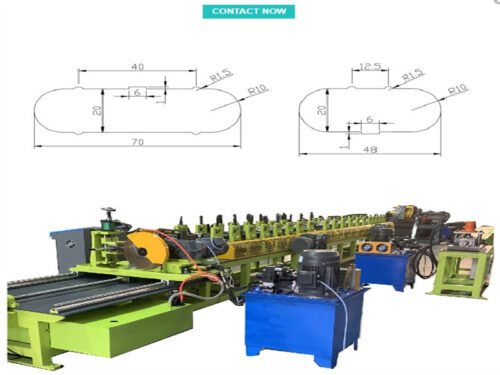

- Customizable Profiles – In addition to standard round tubes, the equipment can be easily adjusted to produce square, rectangular, oval, or custom-shaped profiles, providing greater flexibility for different industrial applications.

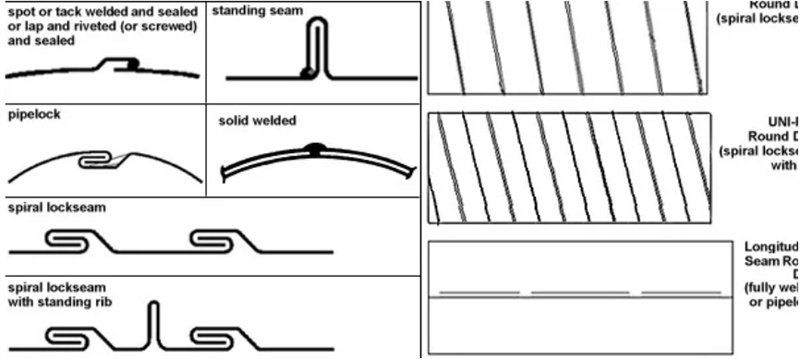

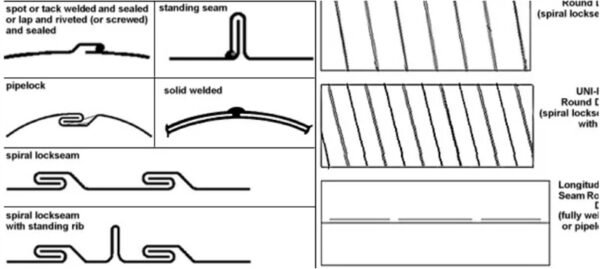

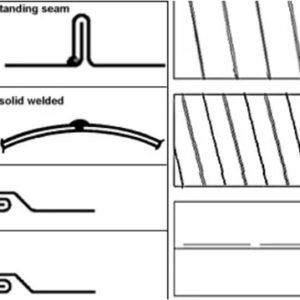

- Optional Welding Integration – Depending on production requirements, the line can be equipped with high-frequency (HF) or TIG welding systems, which seamlessly join the edges of the metal strip, ensuring a clean and strong weld seam.

- Heavy-Duty Structure – Built with a robust steel frame and reinforced base, the machine offers exceptional durability and stability, reducing vibration and extending the lifespan of all mechanical components.

- Low Waste Production – Thanks to its optimized forming design and precise feeding control, material utilization is significantly improved, resulting in minimal scrap and lower production costs.

Working Process

- Material Loading – A Coil of steel or aluminum is placed on the decoiler.

- Uncoiling – The Metal strip is unrolled and fed continuously.

- Pre-Cutting (Optional) – Material can be cut before entering the forming section.

- Roll Forming – The strip passes through forming stations to achieve the target tube shape.

- Welding (Optional) – Tube edges can be welded using HF or TIG welding systems.

- Sizing & Straightening – The tube passes through sizing rollers to ensure correct dimensions.

- Cutting – A hydraulic or flying saw cuts tubes to precise lengths.

- Output – Finished tubes are conveyed, stacked, and ready for packaging.

Applications

- Rainwater Gutter and Downspout Systems

- Construction and Structural Tubes

- HVAC Ducting and Ventilation

- Furniture and Interior Design Profiles

- Automotive Components

- Industrial and Manufacturing Tubes

Customization Options of locked tube Roll Forming machine

We offer fully customizable designs according to your production requirements:

- Tube shape and size

- Welding configuration

- Material type and thickness

- Cutting system options

- Automation level and electrical brand (Siemens, Schneider, Delta, etc.)

Request a Quote

For more information or to receive a personalized quotation, please fill out the contact form below.

Our sales engineers will respond within 24 hours with a detailed proposal and layout drawing.

Reviews

There are no reviews yet.