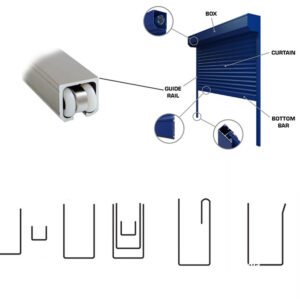

Professional Garage Door Track Roll Forming Machine

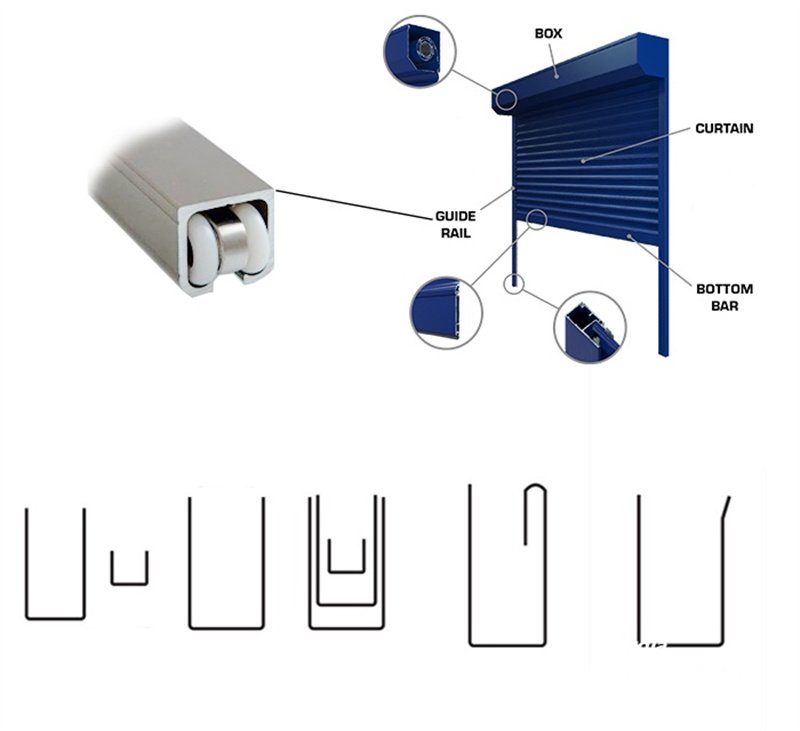

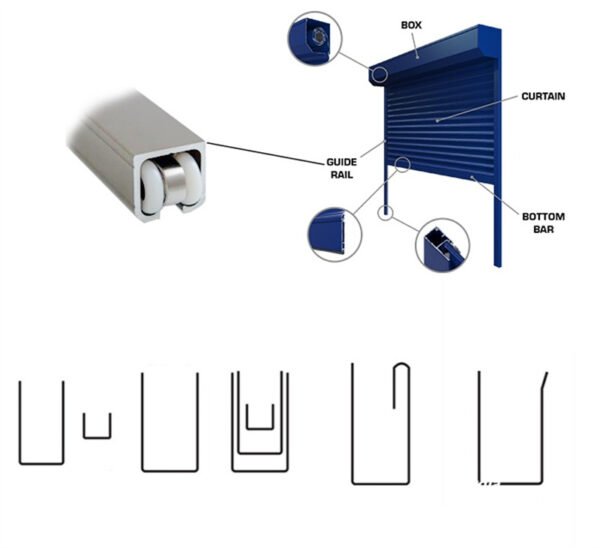

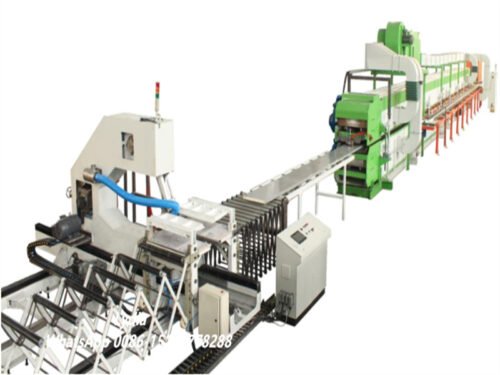

Our high-performance roll forming system specializes in manufacturing precision U-channel guide rails for garage doors. With CE certification and fully customizable configurations, this complete production line delivers exceptional efficiency with operating speeds reaching 18 meters per minute.

Key Features & Technical Specifications

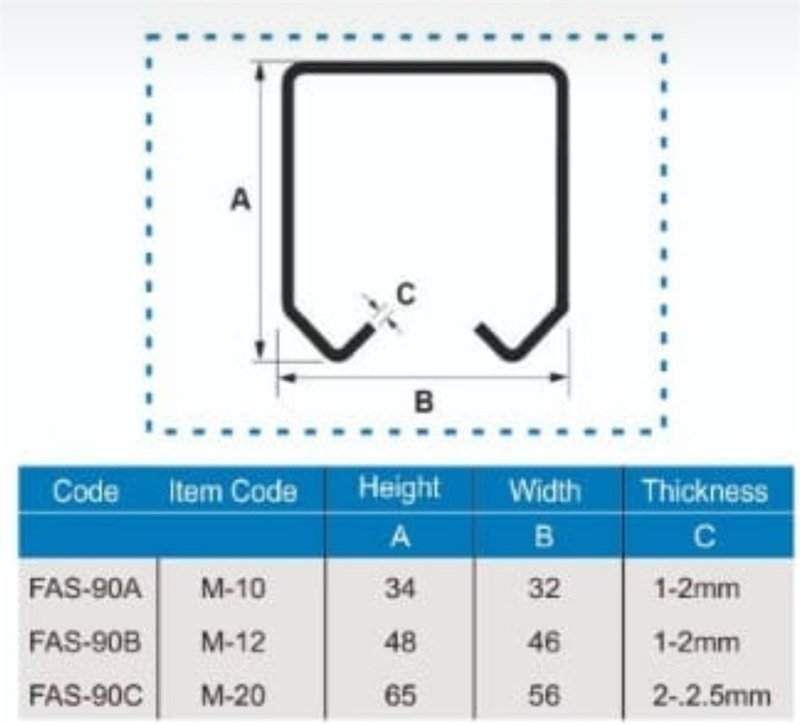

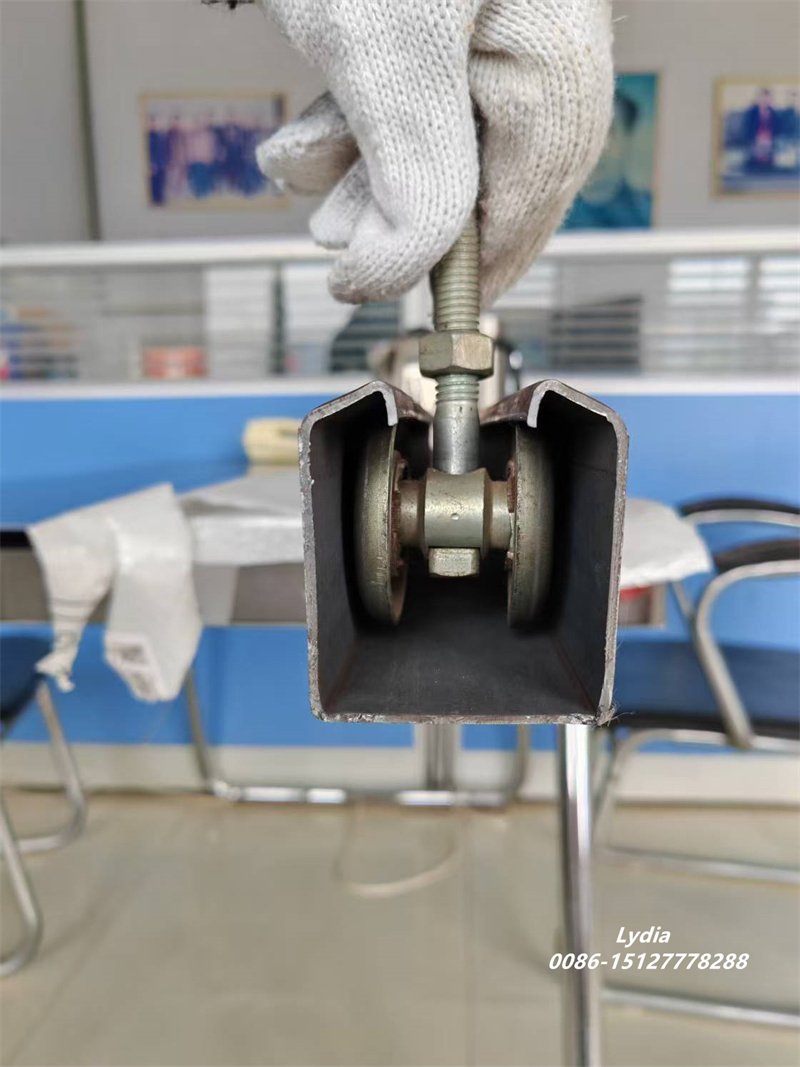

The machine processes a wide range of materials including 0.3-2mm cold-rolled steel, galvanized steel, and aluminum alloys. It features 12-16 forming stations that progressively shape metal into precise U-channel profiles, ensuring consistent quality. The system incorporates a heavy-duty hydraulic decoiler with 3-5 ton capacity and operates within a compact 9m×1.5m×1.5m footprint. Advanced PLC controls with user-friendly touchscreen interface allow for precise adjustments and monitoring.

Production Advantages the equipment offers multiple smart manufacturing benefits:

-

Continuous operation with flying cut technology maximizes output

-

Quick-change profile system reduces downtime between production runs

-

Hardened steel rollers with chrome plating ensure long-lasting performance

-

Robust 70mm solid steel shafts provide exceptional durability

-

Real-time monitoring maintains consistent product quality

Complete Automated Workflow

Coil loading → Progressive forming → Hydraulic pressing → Precision cutting → Automated stacking

Technical Parameters of L-shape Machine

| Item | Specification |

|---|---|

| Voltage | 380V, 50Hz (customizable as per customer request) |

| Material Thickness | 1.0 – 2.0 mm |

| Yield Strength | ≤ G345Mpa |

| Processing Material | Galvanized sheet Q195–Q235 |

| Working Speed | 0–15 m/min |

| Main Motor Power | 7.5 kW |

| Table Frame | 300 H beam |

| Roller Stations | 10 stations |

| Roller Material | 45# steel, quenched, precision-machined, hard chrome-plated (HRC55–60) |

| Shaft Diameter | Φ80 mm |

| Shaft Material | 45# steel, heat-treated (HRC55–60) |

| Transmission Method | By chain |

| Roller Stand Structure | Middle wall plate, 18 mm thick |

| Cutting Type | Hydraulic cutting |

| Cutting Power | 5.5 kW |

| Length Measuring Method | Automatic encoder measuring |

| Cutting Tolerance | 3000 mm ± 1.0 mm |

| Feeding Rollers | 1 set |

| Guiding Rollers | 2 sets |

| Leveling Rollers | 3 up + 4 down |

| Roller Diameter | 50 mm |

| Leveling Power Supply | Pulled by main transmission motor |

| Decoiler Loading Capacity | 3 tons |

| Uncoiling Width | 500 mm |

| Inner Diameter Range | 450–550 mm |

| Receiving Table Size | 3.0 × 1.0 × 0.9 m |

| Roller Diameter (Receiving) | 55 mm |

| Control System | PLC + Touch Screen + Encoder (Omron) + Transducer (Delta) |

| Function of PLC System | Automatic length & quantity measurement, data input via touchscreen |

Versatile Industry Applications

This flexible system serves multiple sectors:

-

Residential and commercial garage door manufacturing

-

Industrial sliding gate production

-

Elevator guide rail fabrication

-

Custom metal channel applications

Reviews

There are no reviews yet.