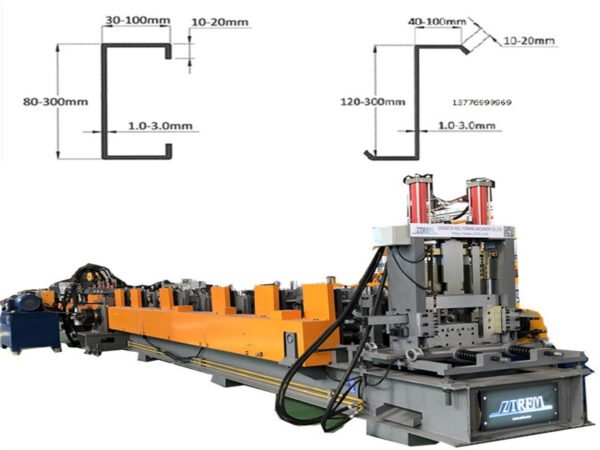

Fully Automatic C/Z Purlin Roll Forming Machine – Product Overview

Our fully automatic C/Z purlin roll forming machine is engineered for high-speed, precision production of structural purlins from a variety of coil materials, including cold-rolled, hot-rolled, and galvanized steel. With a maximum yield strength support of Q195/Q235B (1–3mm) and G550/S350D (up to 2.5mm), this system ensures reliability and performance for industrial construction applications.

CZ Purlin Roll Forming Machine – Simple Version vs. Standard Version

Our CZ purlin roll forming machines are available in two versions – a simple version (USD 44,000) and a standard version (USD 54,000). Both models are designed for reliable production of C and Z steel purlins, but they differ in configuration, operation, and efficiency.

1. Material & Capacity

| For Q195Mpas/Q235 material, max rolling thickness is 3.0mm. | For Q195Mpas/Q235/Q345B material, max rolling thickness is 3.0mm. |

| Machine weight: around 10 Ton | Machine weight: around 11 Ton |

| Feeding and leveling part | Feeding and leveling part |

2. Feeding & Leveling System

| Simple version, with chain drive to make the feeding rollers run actively to take the material into the machine, very smoothly, save labor strength. | 1) There is electric button here, can adjust the feeding automatically

2) With clutch device at the feeding part, when feeding, make the clutch down, it is very easy to feeding the material into the machine, after the material entry into the machine, this part no need run, so take the clutch on, to ensure it not affect the roll former working. |

3. Punching & Pre-Shearing System

| For simple one, pre-punching is swing arm punch, with less power than direct punching. And swing arm punching not as easy adjustment as direct punching when want to adjust hole position. | For simple version, the pre-shearing can just shearing material like a electric scissor.

For standard version, you can set length on the PLC with pre-shearing device work together, it is one part of the roll former. |

| Punching: Include 1 set single hole punching and 2 set double hole punching | Punching holes: Including 1 set single hole punching and 2 set double hole punching unit |

| Servo motor power: 22KW | Servo motor power: 30KW |

| Roller station: 17 rows , 11 rows for C and Z changing | Roller station: 18 rows , 13 rows for C and Z changing |

| Size adjustment by pressing buttons on the machine ( like Nokia phone ) | Size adjustment by input data on the screen directly. (like smart phone) or press button |

| Hydraulic pump station: 7.5kw | Hydraulic pump station: 11kw |

|

Other points are all same. |

|

Both machines share the same overall design concept, but the standard version offers higher automation, easier operation, and more powerful performance. The simple version is a more economical choice for customers who want reliable production with basic automation, while the standard version is ideal for users who need efficiency, precision, and modern control.

| No. | Details | Parameter |

|---|---|---|

| 1 | Decoiler | Loading: 5T Width: 600 mm Inner Diameter: 450–550 mm |

| 2 | Feeding & Leveling | Rollers: 3 up, 4 down Material: Cr15 Diameter: 75 mm Width adjustment: Automatic by button |

| 3 | Pre-Punching System | 3 punching stations (single hole, double hole, waist hole) Mold material: Cr12MoV |

| 4 | Main Roll Forming System | Base frame: U beam welded steel Roller stations: 18 rows Shaft diameter: Φ90/Φ75 Roller material: Cr12 heat-treated (HRC 58–60) Transmission: Chains Speed: Max. 32 m/min (without punching) Servo motor: 22 kW |

| 5 | PLC Control System | Touch screen control Language: Chinese/English (customizable) Auto length & quantity measurement Encoder: Omron (Japan) |

| 6 | Post-Cutting System | Hydraulic stop-cut Power: 11 kW Blade: Cr12MoV Accuracy: ±1.0 mm / 3000 mm |

| 7 | Hydraulic Station | Oil: 46# hydraulic Components: Tank, pumps, pipes, solenoid valves Cooling: Air cooling system |

Reviews

There are no reviews yet.