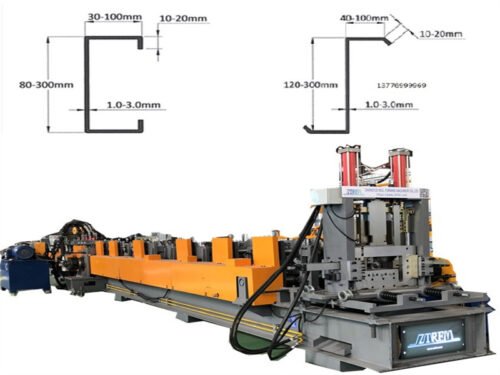

Description of L Purlin Roll Forming Machine

This high-quality L steel channel purlin making machine delivers exceptional flexibility and efficiency for metal angle iron production. Its standout feature is the quick size adjustment capability, allowing operators to produce various L purlin dimensions without replacing rollers, spacers, or cutters—significantly reducing downtime. The machine supports an infinite size range within its operational limits, minimizing material waste while maintaining precision.

Material & Capability of L Angle Iron Roll Forming Machine

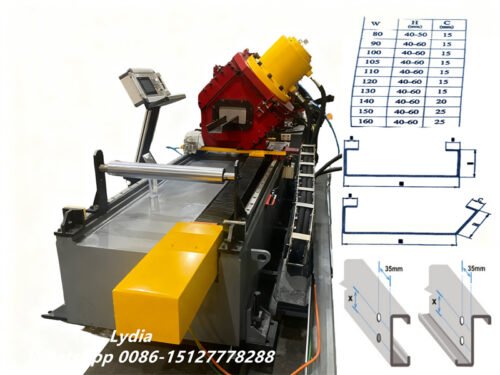

Material Thickness: 1–3 mm (PPGI, GI)

Applicable Width: 50–200 mm

Frame Structure: 16×290×580 mm panel with H350×10 mm base frame

Cutting & Punching: Cr12 hardened steel; optional punching die included

An optional punching system enhances functionality, enabling holes to be added at any position on the web or flange. Designed for user-friendly operation and low maintenance, this machine is ideal for workshops seeking adaptable, high-output purlin fabrication.

Machine Workflow:

Decoiler → Feeding Device → Roll Forming Unit → Hydraulic System → PLC Control → Cutting Unit → Output Table

| Component | Specifications |

| 1. Decoiler | Inner Ø: 450–550 mm, Outer Ø: Max 1500 mm, Max Load: 1500 kg, Manual or Hydraulic |

| 2. Feeding Device | Integrated precision feeding mechanism |

| 3. Roll Forming Machine | 8 Roller Stations, Shaft Ø: 70 mm (Solid, 45# Steel), Roller: GCr15 with Chrome Coating, Speed: ~15 m/min |

| Motor Power: 5.5 kW (Shanghai Motor), Drive: Chain & Sprocket (1″, 17T, 50 links) | |

| 4. Cutting Device | Blade Material: Cr12, Heat-treated to HRC58–62°, Hydraulic Motor: 4 kW, Pillar Cutting |

| 5. PLC Control System | Touchscreen with English/Chinese interface, PLC: Delta, Encoder: Omron, Accuracy: ±2 mm |

| 6. Hydraulic Pump Station | Motor: 4 kW, Oil Type: 46#, Cooling: Fan, Valves: Huade Brand |

| 7. Output Table | No-power type, Length: 2 m |

Reviews

There are no reviews yet.