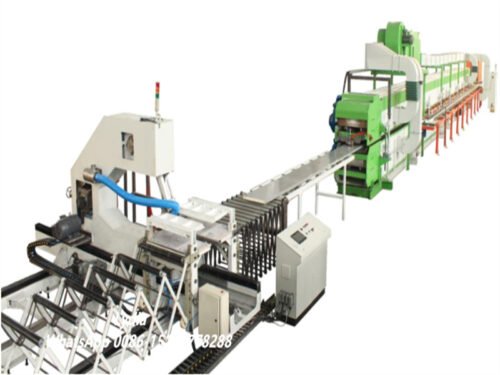

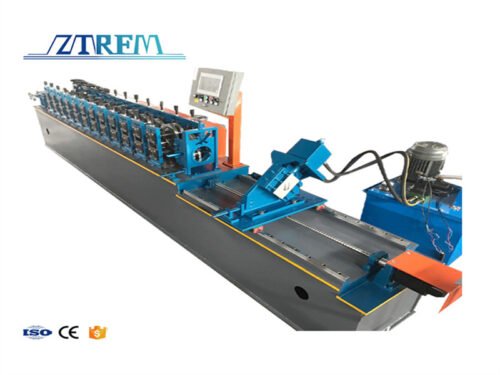

Drywall Door Frame Roll Forming Machine 70mm with Two Turret Heads

Our 70mm Drywall Door Frame Roll Forming Machine is designed for the automatic production of metal door frames with high accuracy and durability. With its two additional turret heads, the machine ensures that door frames are produced perfectly straight, making it a reliable solution for both commercial and institutional building projects.

This metal door frame making machine can be configured as semi-automatic (basic forming only) or fully automatic with online punching for hinge holes, lock holes, and 45° shearing.

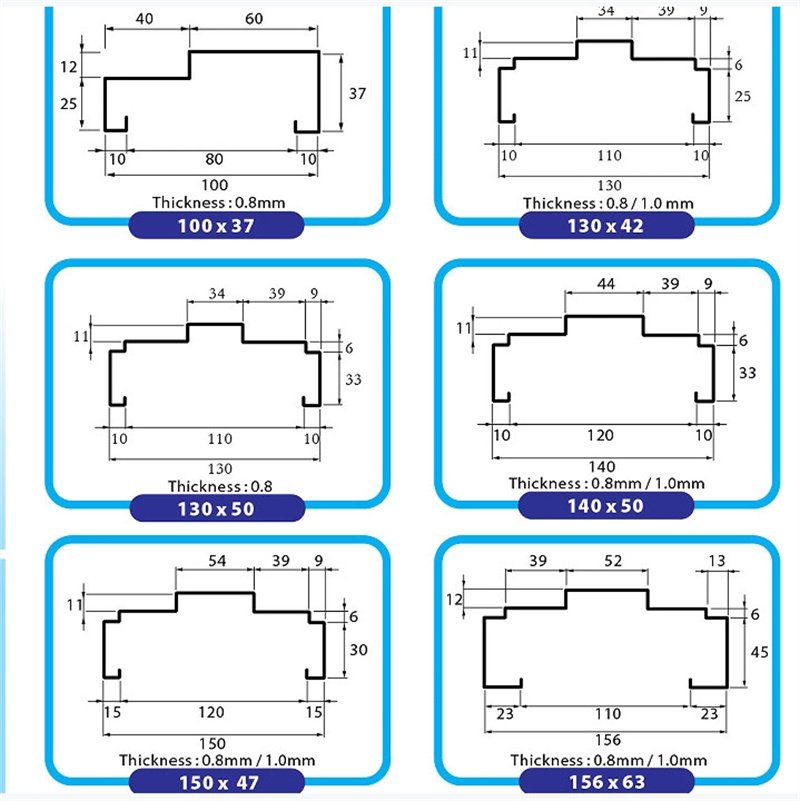

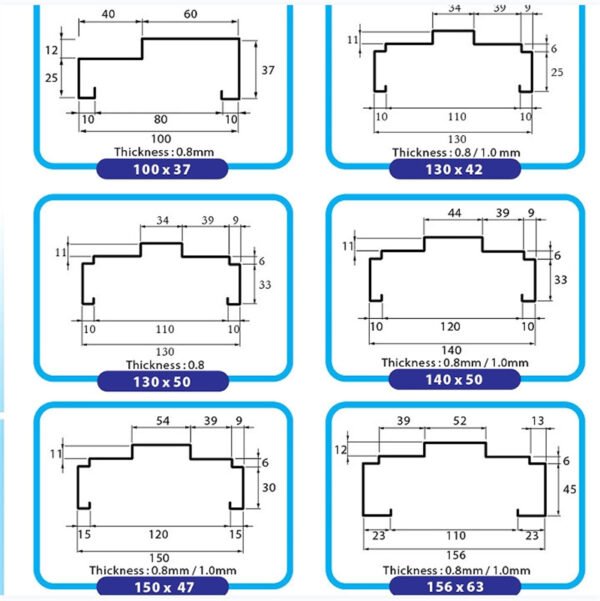

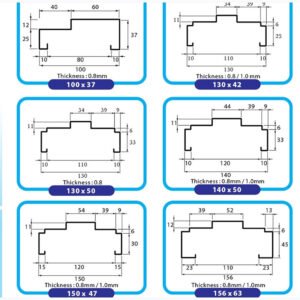

Technical Specifications of light gauge steel door frame roll forming equipment

| Item | Specification |

|---|---|

| Raw Material | GI (Galvanized Steel Coil) |

| Material Thickness | 1.0 – 1.5 mm |

| Rolling Shaft | Ø70 mm, 45# steel, tempered |

| Roller Material | GB-Cr12, quenched HRC 56–58 |

| Rolling Stations | 22 stations |

| Machine Frame | 500# H Steel welded, middle plate 20 mm |

| Work Speed | 0–25 m/min |

| Work Power | 2 × 7.5 kW |

| Bearing | Harbin (famous Chinese brand) |

| Transmission | Chain drive |

| Feeding Device | With three rollers |

Key Features & Advantages of door frame roll forming machine

-

Flexible Options – Choose semi-automatic (forming only) or fully automatic with punching for hinge/lock holes and 45° cutting.

-

Two Turret Heads – Keep the frame straight and dimensionally accurate.

-

Durable Rollers – GCr12MoV rollers ensure long service life and strength.

-

High Precision Forming – 22 stations provide slow, stable forming with 100% accuracy.

-

Flying Tracking & Shearing – Supports higher production speeds.

-

Box Frame Design – Improves safety and aesthetics, easier for operators to handle.

Automatic door frame production line

-

Interior drywall door frames for stud walls

-

Compatible with steel or wood doors

-

Suitable for commercial buildings, warehouses, schools, hospitals, offices

-

Knock-down (KD) drywall frames for quick installation

Reviews

There are no reviews yet.