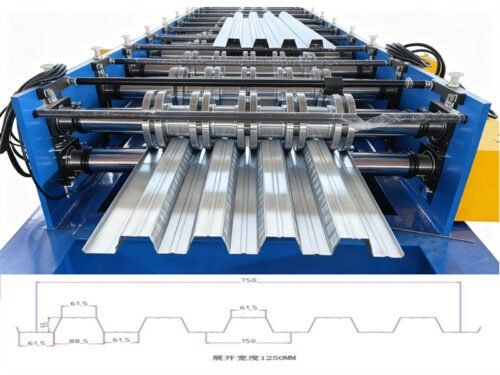

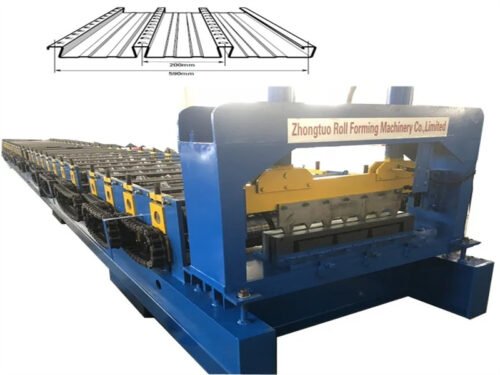

Product Description of Automatic Steel Floor Deck Roll Forming Machine

The floor deck forming machine is a specialized equipment designed for manufacturing floor decks. It continuously rolls and shapes galvanized steel sheets into precise floor deck profiles. These profiles play a vital role in construction as part of composite floor systems, providing strong structural support and enhancing overall floor stability.

Thanks to its efficient forming process, the machine ensures consistent quality, accuracy, and durability, making it an indispensable solution in modern building projects.

Specifications:

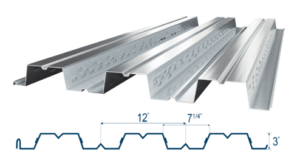

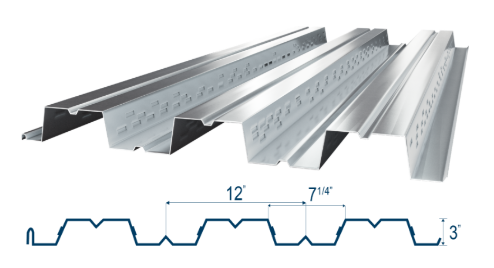

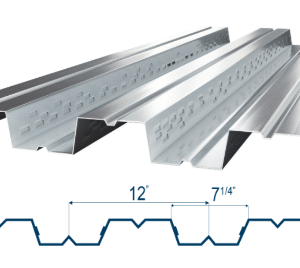

3″ Composite Floor Decking is Available in:

Gauges: 22, 20, 18, 16

Finishes: Galvanized G60, Galvanized G90

Cover Width: 36″

Side Lap Connections: Interlocking

Other Variations: Composite Cellular, Composite Cellular AcousticalThe machine in the below photo are the 3″ Composite Floor Deck machine we made before for our USA customer.

The 3″ composite floor deck is modern concrete slab construction. Engineered with precision embossments, it ensures a superior mechanical bond with concrete. When reinforced with rebar or wire mesh, the deck creates a high-strength composite structure that delivers outstanding durability and stability. Unlike traditional wood formwork, composite steel deck remains in place as a permanent form, saving valuable time and reducing construction costs while providing long-term reinforcement for your building projects.

Product Parameters of Floor Decking Machine

| Category | Details |

|---|---|

| Formed Material | GI (Galvanized Steel) Thickness: 0.7–1.2 mm Width: 1220 mm (customizable) |

| Decoiler | Hydraulic automatic decoiler Manual decoiler (free supply) |

| Main Body | Roller Stations: 33 rows (customizable) Shaft Diameter: 90 mm solid shaft Roller Material: 45# steel, hard chrome plated Machine Frame: 400 H steel Drive: Gearbox transmission Dimension (L×W×H): 15000 × 1800 × 1600 mm (customizable) Weight: 15T |

| Cutter | Automatic cutting Blade Material: Cr12MoV Features: No scratches, no deformation |

| Power | Main Motor: 11 kW × 2 sets (Siemens brand) Hydraulic System Power: 7.5 kW |

| Voltage | 380V, 50Hz, 3-Phase (customizable) |

| Control System | Electric Box: Customized (famous brand) Language: English (multi-language support) PLC: Automatic production with batch, length, and quantity settings |

| Forming Speed | 15–20 m/min (speed depends on profile shape and material thickness) |

Reviews

There are no reviews yet.