Core Pipe Production Capabilities

Our high-frequency welding technology integrates global innovations from American, Japanese and Taiwanese engineering to deliver:

-

HF welded pipe mills with exceptional stability

-

Precision straight-seam pipe systems

-

BG-series stainless steel tube lines

-

Specialized tubing solutions (appliance, refrigeration, HVAC)

-

Advanced cutting systems (cold-cut flying saws)

-

Custom tooling and mold solutions

-

Complete production line engineering

These automated systems achieve outstanding production efficiency while maintaining consistent quality standards.

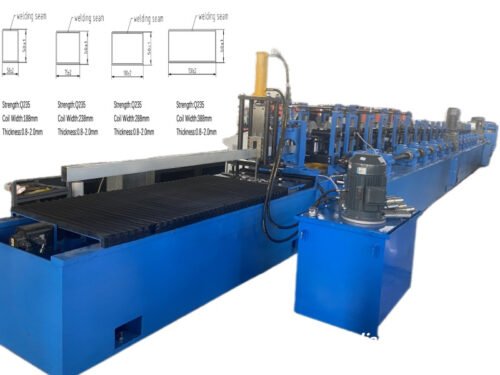

Lock Seam Pipe Forming Technology

Our lock forming equipment produces specialized seamed pipes for:

-

HVAC ductwork systems

-

Automotive exhaust components

-

Custom pipe joining applications

The machines accommodate various lock seam configurations to meet specific application requirements.

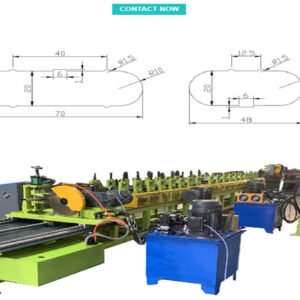

Oval Pipe Production Line Specifications

Technical Parameters:

-

Forming stations: 20

-

Drive system: Chain transmission

-

Production speed: 0-25 m/min

-

Power requirement: 7.5 kW main motor

-

Machine dimensions: 8.5m × 0.8m × 1.45m

-

Structural frame: 350 H-beam with 20mm plate

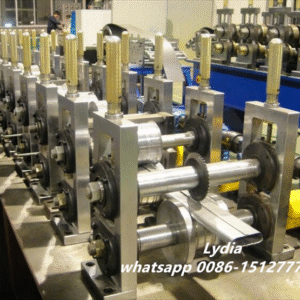

Key Components:

-

Precision rollers (GCr15, HRC 58-60)

-

45# steel shafts (Ø70mm)

-

380V/50Hz power system (configurable)

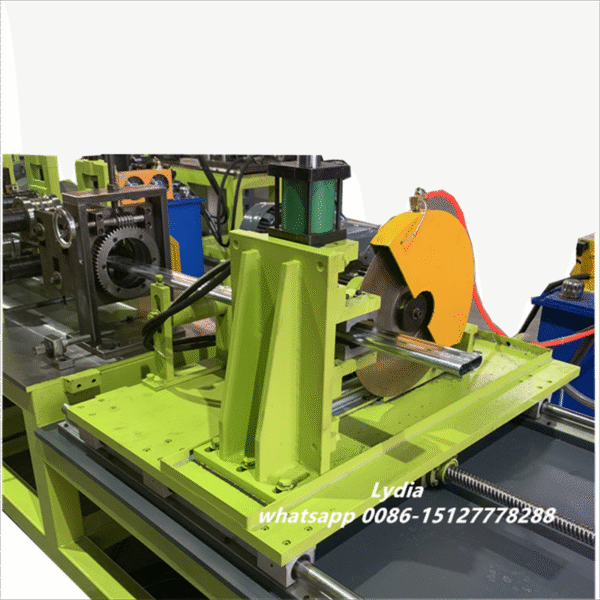

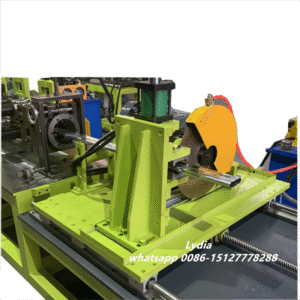

Advanced Cutting System Features

-

Servo-controlled flying cut – Synchronized with line speed for precise cuts

-

Premium blade material – Cr12Mov hardened to HRC 58-62

-

Tight tolerances – ±1.5mm over 3m length

-

Multi-size capability – Handles three pipe dimensions

-

Clean finishes – Maintains pipe integrity post-cutting

Complete Oval Pipeline Configuration

This automated system produces galvanized oval conduits for electrical applications, featuring:

-

Material handling: 3-ton manual decoiler

-

Forming section: 20-stage electro-chrome coated stands

-

Precision cutting: Tracking fly-saw unit

-

Control system: PLC automation

-

Material compatibility: 0.3-0.6mm galvanized/pre-painted steel

The line combines automated operation with manual adjustment capabilities for different material thicknesses.

Technical FAQs

Q: Can a single machine produce multiple oval sizes?

A: While each size requires specific tooling, our modular design allows quick changeovers by swapping roller frames while reusing core components.

Q: How does interlocking differ from welding?

A: Interlocking mechanically folds seams for materials ≤1.2mm, while welding (TIG/laser/HF) is used for thicker materials requiring fusion joining.

Q: What are tube connection methods?

A: Our systems can create necked ends with ribbing for secure push-fit connections between pipes.

Precision Pipe Manufacturing Solutions About Our Company

Cangzhou Zhongtuo Roll Forming Machinery Co., Ltd. is a leading Chinese manufacturer specializing in advanced cold roll forming systems. Established in 2006 and headquartered in Hebei province, we have developed extensive expertise in metal forming technology over nearly two decades.

Our comprehensive product range encompasses:

-

Roof panel forming systems

-

Structural framing equipment (CZ purlins, light steel keels)

-

Decorative metal processing machines (embossing, ceiling/door frame)

-

Specialized pipe production lines

-

Material processing systems (slitting, cut-to-length)

-

Storage solution manufacturing equipment

-

Building material production lines

Reviews

There are no reviews yet.