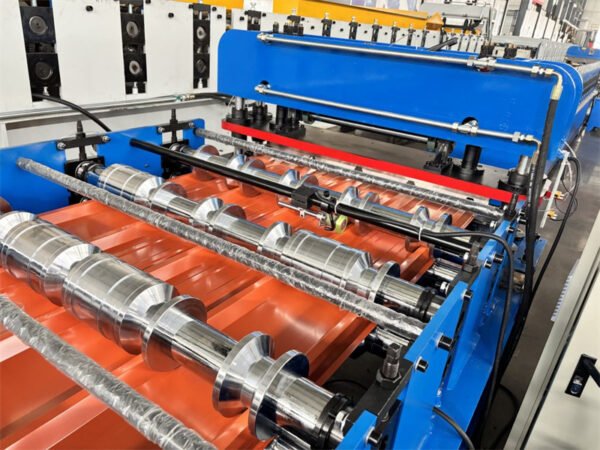

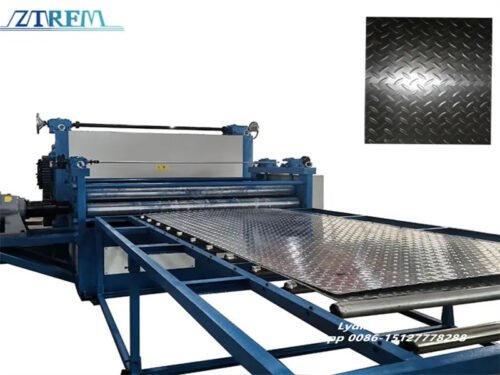

Trapezoidal & IBR Roofing Sheet Roll Forming Machine

The Trapezoidal Roof Roll Forming Machine is designed for producing high-quality metal roofing sheets including trapezoidal and IBR panels. It is widely applied in industrial buildings, warehouses, commercial roofing, and residential housing projects.

Using PPGI, GI, GL, and aluminum materials with thickness ranging from 0.3–0.8mm, this roofing sheet roll forming machine ensures smooth surface panels, precise dimensions, and excellent durability. Equipped with PLC control system, hydraulic cutting, and up to 26 forming roller stations, the machine offers stable performance and a production speed of 15–20m/min.

With a robust 350H steel frame and CNC-machined chrome-plated rollers, it guarantees long service life, minimal maintenance, and consistent product quality. The automatic roof panel making machine can be customized to meet different profile requirements, making it a flexible and cost-effective solution for roofing contractors and sheet suppliers.

We supply IBR sheet roll forming machines for South Africa, trapezoidal roof panel machines for Africa, and metal roofing sheet roll forming equipment for global markets including Asia, South America, and the Middle East.

Main Features and Specifications of Trapezoidal Roof Panel Roll Forming Line

Applicable Materials

-

PPGI, GI, Aluminum, GL

-

Thickness: 0.3–0.8 mm

-

Coil width: 1000/1250 mm (customized per profile)

Decoiler

-

Hydraulic automatic decoiler (manual type provided as free option)

Forming Unit

-

Roller stations: 26 rows (adjustable per requirement)

-

Shaft: solid 80 mm, 45# steel, heat-treated

-

Rollers: 45# steel, CNC processed, hard chrome-plated (HRC 55–60)

-

Frame: 350# H-beam steel

-

Transmission: Chain drive

-

Dimension: 10500 × 1600 × 1600 mm (customized)

-

Weight: Approx. 11.5T

Cutting System

-

Hydraulic cutting, post-cut type

-

Blade material: Cr12Mov, anti-scratch, anti-deformation

Power & Control

-

Motor power: 5.5 kW

-

Hydraulic system: 5.5 kW

-

Voltage: 380V, 50Hz, 3 Phase (optional customization)

-

PLC & control cabinet: Famous brand, multilingual interface

-

Touch screen: User-friendly, supports batch setting, length, and quantity control

Production Speed

-

15–20 m/min (depending on sheet thickness and profile)

If you are looking for a reliable steel roofing sheet forming machine with high efficiency, durability, and low operation cost, our trapezoidal roof panel roll forming line will be your best choice.

Contact us today for detailed specifications, pricing, and technical support.

Reviews

There are no reviews yet.