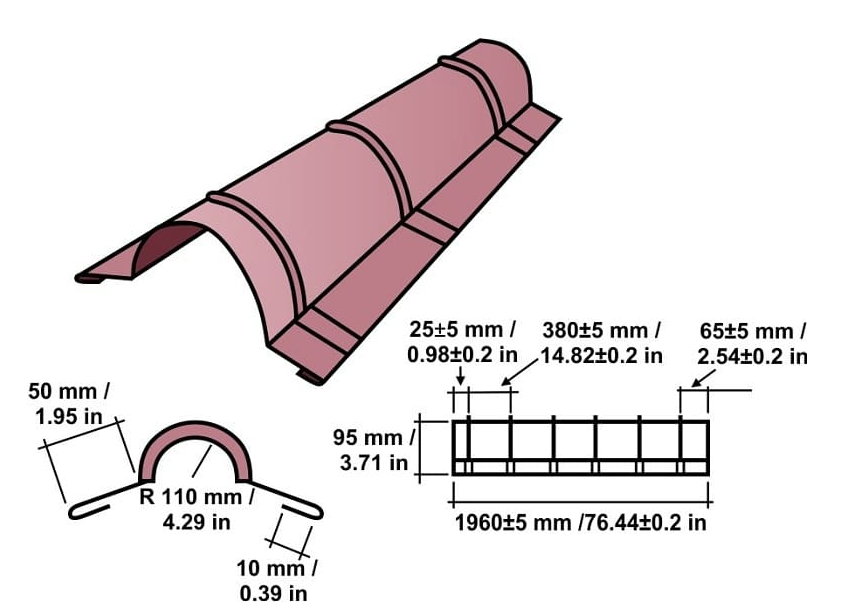

Introduction to Ridge Capping in Roofing Systems

In modern construction, ridge capping tile plays a crucial role in ensuring the durability and watertight performance of roofing systems. It is placed at the apex where two roof slopes meet, creating a clean, weatherproof, and maintenance-free finish. Without ridge capping, however, rainwater can easily seep into the building structure, especially around chimneys or roof joints, which may cause significant interior damage.

Therefore, ridge capping is not only functional for waterproofing but also important for aesthetics. It improves the overall appearance of the roof while reducing long-term maintenance.

Working Process

The ridge capping roll forming production line follows this sequence:

Uncoiling → Feeding with Guide → Roll Forming → Cutting → Products Collecting

As a result, the process is streamlined, efficient, and consistent in quality.

Why Choose Metal Roofing with Ridge Capping?

Metal roofing, on the other hand, has become a popular alternative to traditional composite materials. This is because it is:

- Long-lasting – It can withstand decades of use.

- Weather-resistant – It provides reliable protection against rain, snow, and extreme heat.

- Low-maintenance – Ridge capping prevents leaks and consequently reduces repair costs.

- Visually appealing – It offers sharp, bold lines that enhance modern building designs.

Moreover, with the use of Colorbond high tensile steel (G550MPa), the ridge cap ensures strength and stability. As a result, it becomes ideal for industrial, commercial, and residential projects.

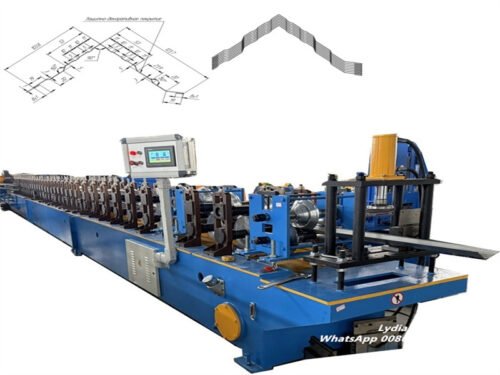

Machine Description and Specifications

In addition, the machine itself is designed with precision. Its specifications are as follows:

| Item No. | Description | Specification |

|---|---|---|

| 1.0 | Roll forming machine | – |

| 1.1 | Rolling speed | 5–10m/min (excluding cutting time) |

| 1.2 | Rolling thickness | 0.42mm |

| 1.3 | Raw material | 400mm width, G550MPa Hi Tensile Colorbond Steel |

| 1.6 | Dimension | 1500 × 1700 × 1500mm (approx.) |

| 1.7 | Effective width | 60mm |

| 1.8 | Roller stations | 16 stations |

| 1.9 | Roller material | 45# forged steel, chrome coated |

| 1.10 | Shaft diameter | Φ70mm, 45# forged steel |

| 1.11 | Transmission | By chain, 1 inch |

| 1.12 | Chain material | 45# forged steel, frequency quenched, 12A |

| 1.14 | Cutting blade material | Cr12Mov, quenched HRC 58–62° |

| 1.15 | Cutting tolerance | ±1.5mm per 6m |

| 1.16 | Frame | H-type steel |

In conclusion, the Galvalume PPGI Ridge Capping Roll Forming Machine is the ideal solution for manufacturers seeking durable, cost-effective, and precision-made roofing ridge caps. Moreover, with advanced roll forming technology, hydraulic cutting, and PLC control, this machine guarantees efficient production and superior quality output.

Therefore, whether you are working on industrial warehouses, commercial buildings, or residential housing, this machine will deliver long-lasting ridge capping tiles that enhance both protection and appearance.

When compared with other machines, this equipment offers:

- Reasonable Price – Competitive cost without sacrificing quality.

- High Quality – Built with precision engineering and strong materials.

- 12-Month Warranty – Guaranteed after-sales support.

- Durable Design – Long service life with minimal maintenance.

- Reliable Performance – Stable operation and accurate cutting.

In fact, these advantages make it one of the most reliable investments for roofing production.

Reviews

There are no reviews yet.