Galvanized Steel Coil Slitting and Recoiling Machine | Zhongtuo ZT5 Recoiler

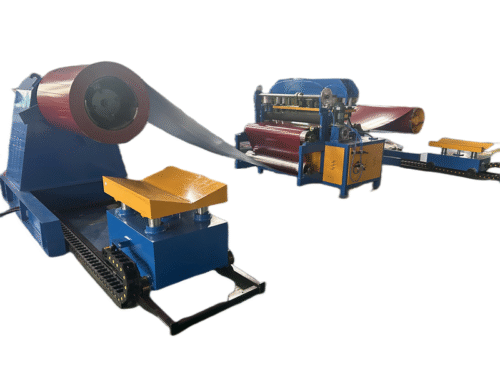

Are you looking for a slitting and recoiling solution that is reliable, durable, and cost-effective? The Zhongtuo ZT5 Recoiler is designed to meet the needs of coil processing lines across multiple industries. From roofing sheet production to door and window frame manufacturing, this machine ensures consistent quality and efficiency. Moreover, its compact structure makes it suitable for both light-gauge trim shop operations and heavy-gauge, high-speed coil processing lines.

Working Process

Uncoiling → Feeding with guide → Embossing (optional) → Roll forming → Recoiling → Finished coil collection

Why Choose Zhongtuo Recoiler?

First of all, the ZT5 model can easily adapt to different sheet sizes from coil to coil. Additionally, it handles soft steel up to 1.5 mm thickness, which provides greater flexibility for manufacturers. Furthermore, the compact design not only saves floor space but also reduces waste, increases productivity, and lowers inventory requirements. As a result, it is a smart choice for companies aiming to optimize coil handling processes.

Technical Parameters Slitting Recoiler

To make specifications clearer, here is the technical table of the complete recoiling system:

| Section | Parameter | Specification |

|---|---|---|

| Uncoiler | Frame | Steel plate structure |

| Uncoiling type | Cantilever pneumatic brake uncoiling | |

| Brake type | Pneumatic brake | |

| Loading capacity | ≤5T, inner coil diameter φ490–520mm (paper tube core) | |

| Coil diameter | ≤1000×1300mm (raw coil) | |

| Loading | Hydraulic trolley | |

| Quantity | 1 set | |

| Embossing Machine | Type | Vertical two-roll double-sided embossing |

| Thickness range | 0.26–0.6mm aluminum coil | |

| Pattern | Orange peel texture | |

| Embossing depth | 0.1–0.3mm adjustable | |

| Line speed | 5–40m/min (adjustable) | |

| Roller specification | ø410×1300mm, finished width ≤1250mm | |

| Roller material | Forged steel | |

| Roller heat treatment | Overall quenching, medium-frequency quenching | |

| Roller hardness | ≤HRC52 | |

| Engraving | CNC engraved | |

| Transmission | Frequency speed control | |

| Pressure regulation | Reducer with electric adjustment | |

| Center height | 850mm | |

| Electrical control | Independent cabinet | |

| Pattern roller | Replaceable | |

| Inverter brand | Shenzhen Ouke | |

| Quantity | 1 set | |

| Recoiler | Frame | Steel plate structure |

| Recoiling type | Cantilever pneumatic brake recoiling | |

| Brake type | Pneumatic brake | |

| Loading capacity | ≤5T, inner coil diameter φ490–520mm (paper tube core) | |

| Coil diameter | ≤1000×1300mm (finished coil) | |

| Power | 22KW | |

| Loading | Hydraulic trolley | |

| Quantity | 1 set | |

| Overall | Line dimension | 7000×3800×1700mm (subject to actual machine) |

| Weight | 10,000Kg (subject to actual machine) |

Advantages of Zhongtuo ZT5 Recoiler

- Reasonable Price – affordable without compromising quality.

- High Quality – robust steel structure with strict heat treatment.

- 12-Month Warranty – full service support available.

- More Than 10 Years of Experience – trusted by global partners.

- Durability – forged rollers ensure long service life.

- Reliability – stable performance in continuous production.

Reviews

There are no reviews yet.