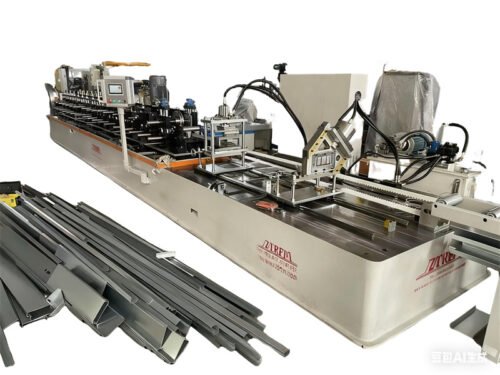

Hat-Shaped Ceiling Stud & Omega Profile Roll Forming Machine

High-Precision Metal Furring Channel Production Line by ZTRFM Machine

In modern construction and interior systems, the demand for lightweight, durable, and precisely formed ceiling and partition profiles is rapidly growing. As a result, many manufacturers are moving away from traditional manual processing and turning toward automated solutions. Therefore, the Hat Shaped Ceiling Stud Omega Profile Making Machine, developed by ZTRFM, offers a reliable and efficient way to upgrade production capacity while ensuring consistent quality.

Moreover, with Zhongtuo’s advanced engineering experience and global service capability, this ZTRFM machine delivers faster setup, smarter operation, and higher output—helping factories stay competitive in a changing market.

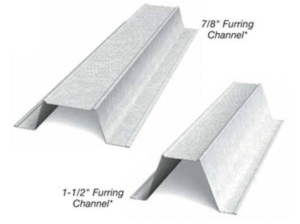

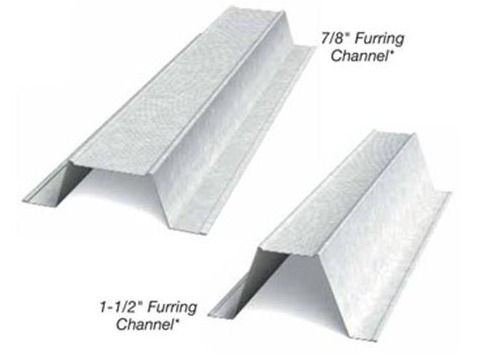

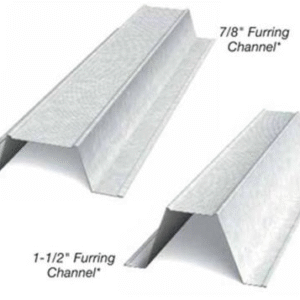

The furring channel is a hat-style, corrosion-resistant framing profile designed for leveling and supporting wall and ceiling finishes. When applied to concrete walls, the channel is positioned vertically and secured with concrete nails or power-driven fasteners before gypsum boards are fixed directly onto the framing with screws.

For suspended or dropped ceilings, the furring channel can be mounted beneath the structural slab using tie wire, clips, screws, or nail-type fasteners, creating a stable attachment surface. Using thicker gauges allows for longer spans and increased load-bearing performance, making it suitable for more demanding installation requirements.

This profile provides a non-combustible substrate for both interior and exterior wall systems and effectively helps correct uneven surfaces. Standard depth options include 7/8 inch and 1-1/2 inch, available in 25, 20, 18, and 16-gauge steel. Typical lengths are 10 ft and 12 ft, with customized sizes offered upon request. The hemmed-leg furring channel configuration is manufactured exclusively in 25-gauge material.

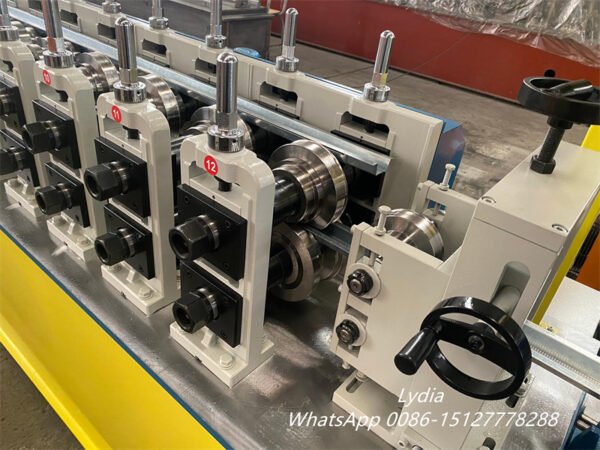

Technical Specifications of Hat-Shaped Ceiling Stud & Omega Profile Roll Forming Machine

| Category | Specification |

|---|---|

| Forming Material | PPGI / GI / Aluminum (0.5–1.2mm) |

| Decoiler | Hydraulic automatic / Manual (free) |

| Roller Stations | 12 rows (customizable) |

| Shaft Diameter | 50mm solid shaft |

| Roller Material | 45# steel with hard-chrome coating |

| Drive System | Gearbox transmission |

| Machine Size | 5500 × 800 × 1200mm (adjustable) |

| Cutting System | Automatic cutting, CR12MoV |

| Motor Power | 7.5kW + 5.5kW hydraulic system |

| Voltage | 380V 50Hz 3-Phase (optional customization) |

| Forming Speed | 60–70m/min (depends on profile & thickness) |

| Control System | PLC automatic control, multi-language support |

This structured configuration ensures stable forming performance while maintaining long-term reliability—one of the core strengths of Zhongtuo Equipment.

Main Application Fields

The Metal Furring Channel Roll Forming Machine from Zhongtuo Machine is widely used across multiple building systems, including:

- Ceiling Suspension Systems

It produces T-shaped and hat-type keels that connect with L-shaped fittings, ensuring secure ceiling installation. - Interior Partition Walls

It supports non-load-bearing wall structures by supplying compatible C- and U-type profiles. - Roofing Support Frames

Some ZTRFM models form reinforced U-shaped sections suitable for lightweight roofing. - Light Steel Modular Construction

It works seamlessly with other Zhongtuo light steel lines to produce prefabricated house components and decorative ceilings.

Three Core Advantages of the ZTRFM Machine

1. Automated Production Reduces Labor Costs

The ZTRFM machine adopts a smart touch-screen control system. As a result, operators can set length, batch quantity, and profile type within seconds. Even new workers can learn basic operation in one hour, and one person can manage 3–4 machines at the same time. Additionally, automatic feeding and waste handling decrease material loss and significantly lower overall production expenses.

2. Flexible Output for Fast-Changing Orders

Since the market increasingly demands small-batch and multi-specification production, Zhongtuo Machine supports rapid mold change in under five minutes. Furthermore, customized profile tooling can be delivered within seven days. Whether producing narrow hat channels, Omega-type studs, or lightweight ceiling furring, the ZTRFM line ensures fast response and shorter delivery cycles.

3. Durable Structure Ensures Continuous Operation

The machine frame is welded from high-strength cold-rolled steel to prevent deformation during long-term use. Meanwhile, cutting blades and transmission gears are made from reinforced alloy materials, extending wear resistance up to five times. In addition, an intelligent fault-detection system monitors voltage and temperature, issuing alerts instantly to reduce downtime and protect core components.

Why Choose Zhongtuo & ZTRFM Machine?

- 18+ years of roll forming expertise

- Exported to more than 90 countries

- ISO, CE, and CAS certified

- Fast installation & long-term technical support

- Customized profile design and turnkey solutions

With Zhongtuo, manufacturers gain not only a machine, but a reliable production partner.

Reviews

There are no reviews yet.