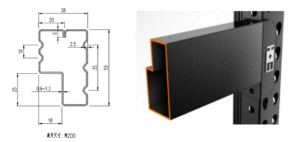

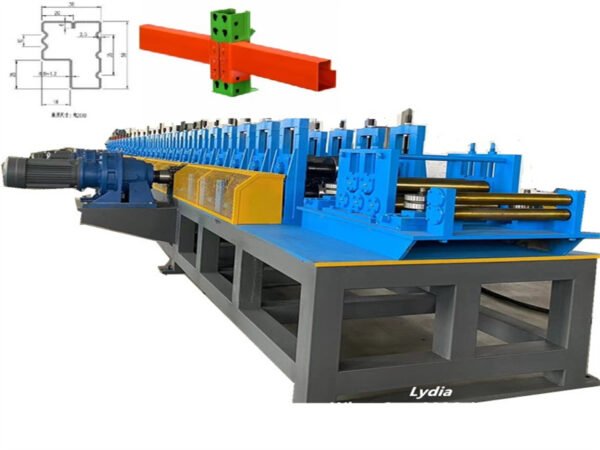

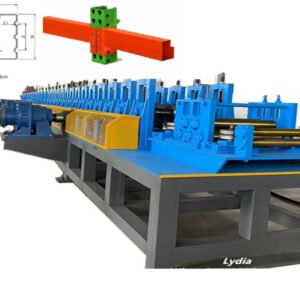

P-Beam Roll Forming Machine

This advanced P-Beam Roll Forming System specializes in manufacturing high-strength shelf support beams for warehouse storage systems. The equipment efficiently processes 0.6-1.2mm thick galvanized steel at speeds of 10-15 meters per minute, making it ideal for producing durable beams used in logistics centers, retail displays, and industrial shelving.

Key Features & Benefits

-

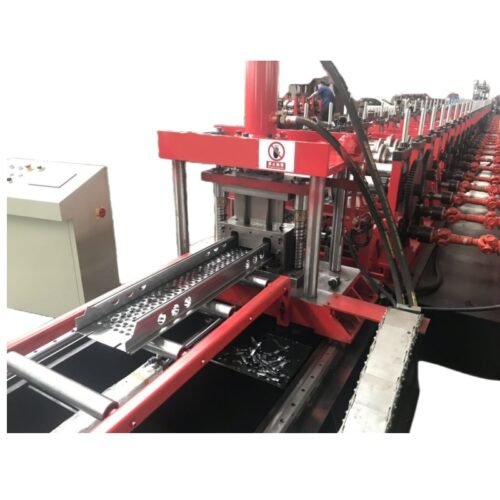

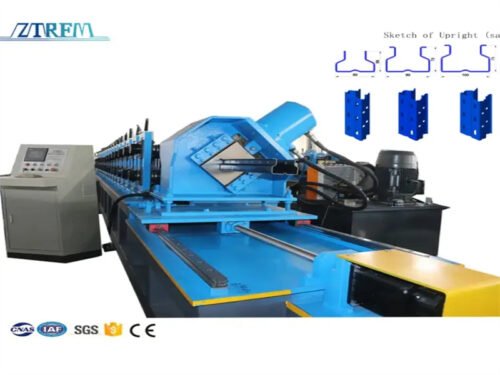

Multi-Specification Production – With 26 forming rollers, only 6 sets require replacement for profile adjustments, enabling quick changeovers between different beam designs.

-

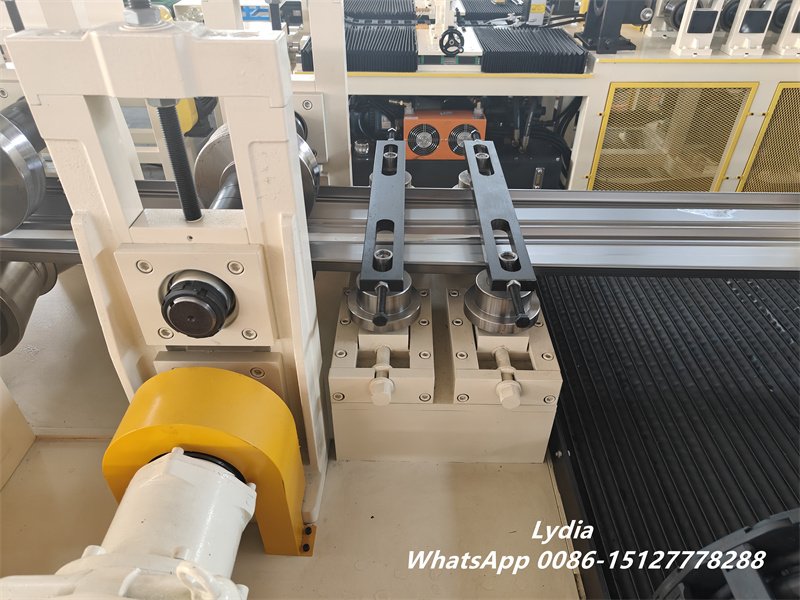

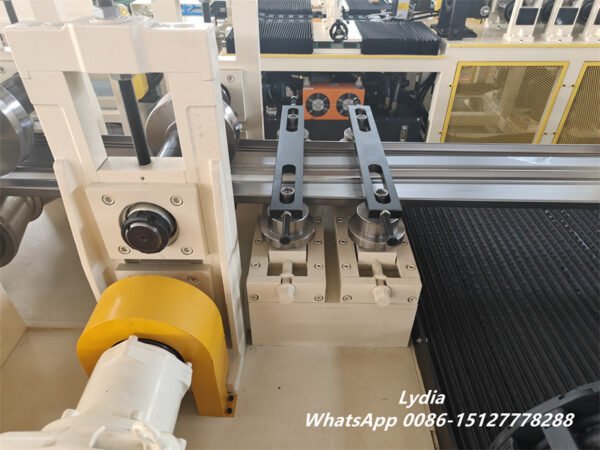

Precision Welding & Cutting – Equipped with dual argon arc welding stations and a high-speed burr-free cutting saw for seamless beam fabrication.

-

Automated Servo Tracking – Ensures synchronized operation between welding, cutting, and material handling for consistent output.

-

High Structural Integrity – Produces P-shaped beams with superior load-bearing capacity, essential for heavy storage applications.

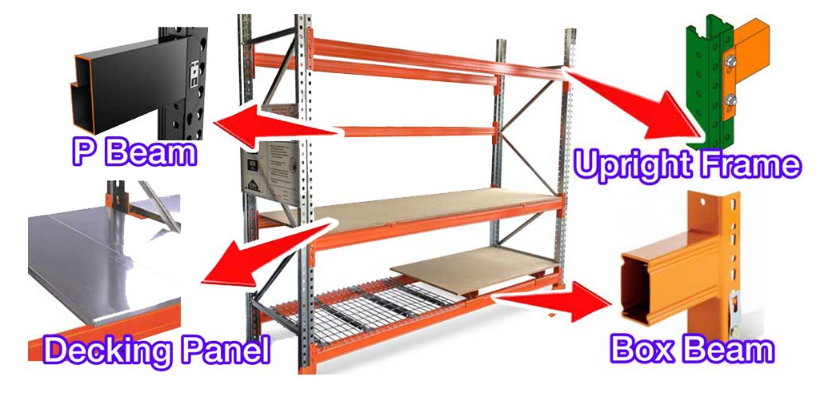

P-Beam Applications

Pallet Rack Systems – Core structural component for adjustable warehouse storage. Industrial Shelving Units – Supports heavy loads in manufacturing and distribution facilities.

Commercial Displays – Used in supermarkets and retail spaces to organize products.

Technical Specifications

| Category | Specification | Details | Remarks |

|---|---|---|---|

| Material | Base Metal | Galvanized Steel | Client Approved |

| Thickness Range | 0.6-1.2 mm | ||

| Uncoiler | Roller Configuration | 7-Roller System (3 Top + 4 Bottom) | Standard material flattening |

| Maximum Capacity | 3 Tons | ||

| Coil Core Diameter | 450-550 mm | ||

| Forming Unit | Guide System | Integrated Design | Supplier Installed |

| Shaft Material | Tempered 45# Steel | ||

| Shaft Diameter | Ø60 mm | ||

| Roller Hardness | Cr12 Alloy (HRC 56-58) | ||

| Forming Stations | 18 Stages | ||

| Operational Speed | 10-15 m/min | Adjustable | |

| Machine Frame | Vertical Arch Structure | Welded Steel Construction | |

| Drive Mechanism | Dual 7.5 kW Motors | Chain-Driven | |

| Safety Features | Full Protective Covers | ||

| Finish & Quality | Surface Finish | Smooth Paint Coating, No Defects | 100% New Equipment Guarantee |

| Optional Upgrades | Hydraulic Decoiler | Available Upon Request |

Production Process

-

Material Uncoiling → 2. Leveling → 3. Roll Forming → 4. Servo-Controlled Welding → 5. Precision Cutting → 6. Finished Product Output

Reviews

There are no reviews yet.