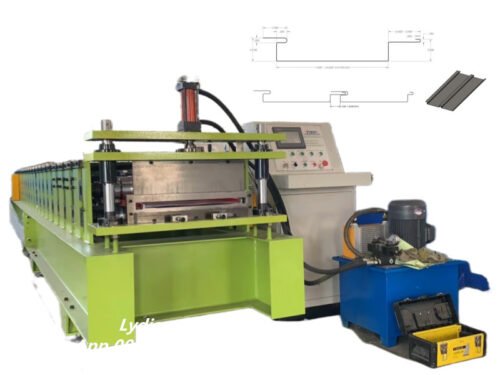

The Metal Wall Cladding Sheet Panel Forming Machine is specially engineered for the automated production of wall cladding panels in bulk. In today’s market, wall cladding sheets come in many different profiles, and the one introduced here is a box-profile style, capable of producing panels that resemble a closed-type exterior metal wall cladding system. Below are sample profile drawings and finished products for reference.

Compared with conventional cladding sheets, this design offers several unique benefits:

- Side punching holes for easier installation.

- Adjustable width for flexible production.

- End bending design, resembling a closed profile.

- Customizable length as required.

- Stronger 3D surface effect.

- Hidden fastening system for a cleaner appearance.

Working Principle & Flow

The machine operates through a series of fully automated steps: material loading by decoiler → leveling (with optional film laminating) → corner cutting & punching → roll forming (with adjustable width) → bending & shearing → finished panel collection on the output table.

- Decoiler: Available in both manual and hydraulic options.

- Corner Cutting: Adjustable width, suitable for multiple panel types.

Technical Features of Metal Wall Cladding Sheet Panel Forming Machine

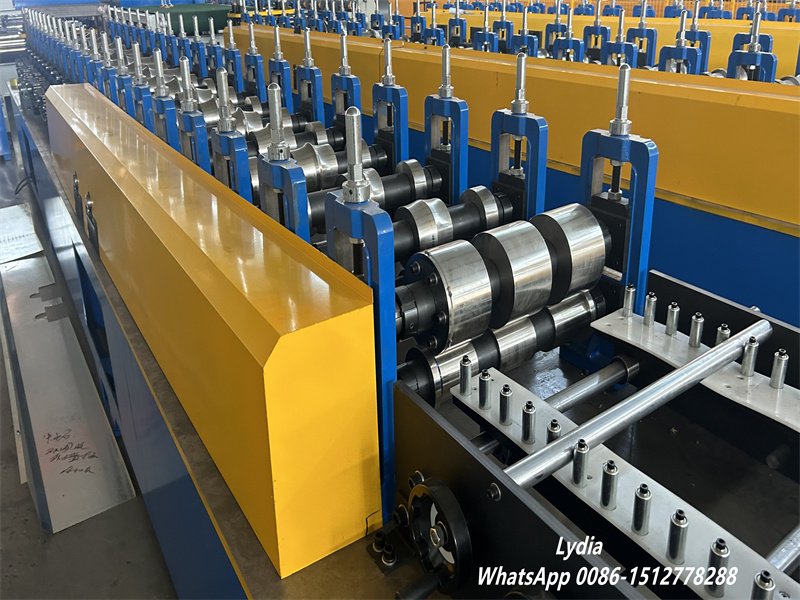

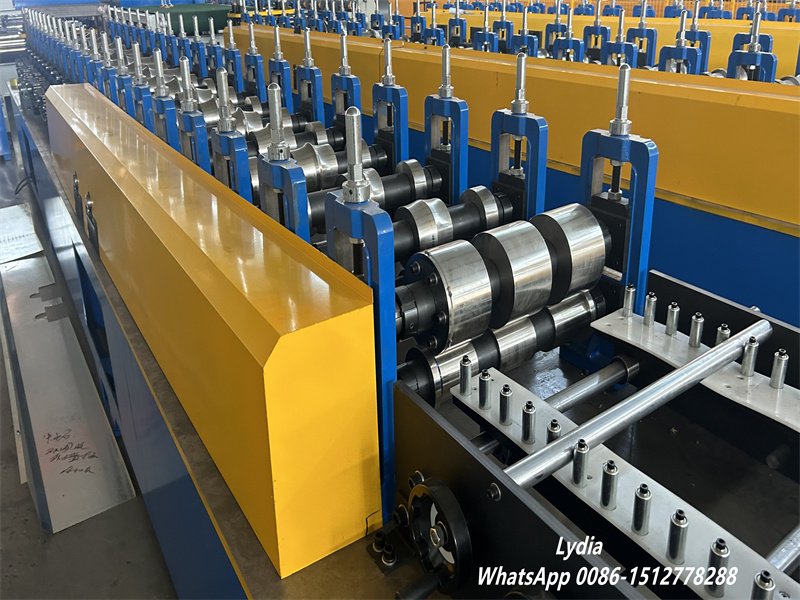

- Rolling Shaft: 65 mm diameter, 45# steel, quenched and precision machined.

- Rollers: GCr15 steel, fine machining, surface hardening HRC 58–62 with chrome coating.

- Frame: 35 mm arch-type structure, supported by 350H beam steel.

- Stations: 16 forming stations, ensuring stable shaping.

- Speed: 10–20 m/min, driven by 5.5 kW servo motor via chain transmission.

- Cutting & Bending: Blades made of Cr12Mov, hardened to HRC 58–62.

The machine is equipped with a Siemens PLC system, frequency inverter, and touch screen (multi-language interface). Key electrical components are from Schneider, while encoders and servo control ensure precision in cutting length, production quantity, and speed adjustment. Safety features include movable switches, leakage protectors, air breakers, radiators, and transformers, ensuring stable operation, long service life, and operator safety.

Reviews

There are no reviews yet.