Understanding Tray and Trunking Cable Tray Roll Forming Machine

High Speed · High Precision · Customizable

Overview

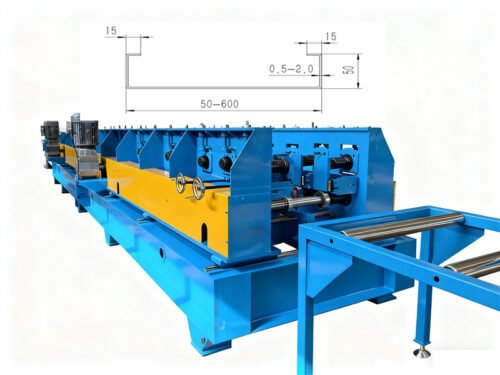

Our cable tray roll forming machine combines Italian design with German manufacturing quality, delivering fast, precise, and stable production of cable trays for commercial and industrial applications. It supports multiple sizes and quick changeover, with both pre-cut and post-cut options.

Key Advantages of Roll Forming Machine

-

High Productivity: 15 m/min working speed

-

Precision Forming: 8 forming stations, Cr12MoV rollers

-

Flexible Operation: Telescopic shaft for rapid size change without tooling

-

Smart Control: Mitsubishi PLC + KINCO touch screen, easy programming

-

Durable Build: Siemens motors, Schneider electrics, SKD11 cutting blades

-

Custom Solutions: Tailored designs to meet your specific requirements

-

Global Service: Technical guidance, installation, and maintenance support

Typical Applications

-

Ladder-type cable trays

-

Trough-type cable trays

-

Perforated trays for electrical wiring support

Main Technical Parameters

| Item | Specification |

|---|---|

| Material Thickness | 0.8–2.5 mm |

| Material Type | Galvanized or black steel |

| Working Speed | 15 m/min |

| Forming Stations | 8 |

| Shaft Diameter | 90 mm (thermal refined 45# steel) |

| Drive System | Gearbox drive, 70 mm shafts |

| Main Motor | 22 kW SIEMENS |

| Cutting | Hydraulic, SKD11 blades |

| Hydraulic Power | 11 kW SIEMENS |

| PLC Control | Mitsubishi |

| Touch Screen | KINCO |

| Electrical Components | Schneider |

1. Cable Support Systems Explained

A cable tray functions as an open framework designed to route and protect electrical wiring systems securely. These structural supports are particularly suited for large-diameter cabling installations, contrasting with smaller wires that typically run through enclosed trunking channels. These systems are especially prevalent in industrial and commercial settings where robust cable protection is paramount.

While sharing visual similarities with galvanized wire channels, cable trays are distinguished by their larger dimensions. Industry standards classify support systems exceeding 200mm in width as cable trays, while narrower variants (below 200mm) are designated as galvanized wire channels.

2. Metal Wire Channel Systems

Metal wire channels feature a trough-like design comparable to cable trays but with reduced dimensions and distinct material characteristics. These components, alternatively called wire ducts, raceways, or conduits depending on regional terminology, serve to neatly organize and protect electrical and data cables along building surfaces.

Available configurations include:

-

Insulated and open-channel variants

-

Compact and divided channel systems

-

Integrated wiring solutions

-

Specialized telecommunications pathways

-

Circular and floor-mounted designs

-

Flexible and covered channel options

3. Comparative Analysis: Cable Trays vs. Metal Channels

Key differentiators between these cable management solutions include:

-

Dimensional Standards:

-

Tray systems: Minimum 200mm width

-

Wire channels: Below 200mm width

-

-

Functional Applications:

-

Trays: Optimized for heavy cable routing

-

Channels: Designed for smaller wire containment

-

-

Design Variations:

-

Trays: Available in multiple configurations (ladder, basket, solid-bottom)

-

Channels: Typically single-profile hot-rolled steel

-

-

Installation Considerations:

-

Tray systems require structural load analysis

-

Channels facilitate final connections to distribution equipment

-

-

Construction Features:

-

Trays: Open-frame design (predominantly cold-rolled steel)

-

Channels: Enclosed structure (galvanized sheet metal)

-

-

Industry Applications:

-

Trays: Preferred in construction projects

-

Channels: Common in interior electrical installations

-

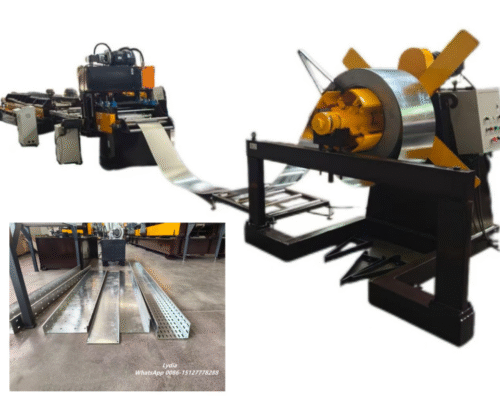

Advanced Cable Tray Manufacturing Technology System Overview

The automated perforated cable tray production line represents a dual-function system engineered for manufacturing slotted C-section profiles for electrical infrastructure applications. This advanced equipment processes medium-gauge steel (0.8-2.0mm thickness) into finished cable support systems.

Key features include:

-

Integrated punching systems for ventilation patterns

-

Tool-less width adjustment mechanisms

-

Flexible cutting options (pre/post forming)

Complete production lines comprise:

-

Material unwinding and straightening systems

-

Precision forming stations

-

Computerized control units

-

Automated stacking and output systems

Reviews

There are no reviews yet.