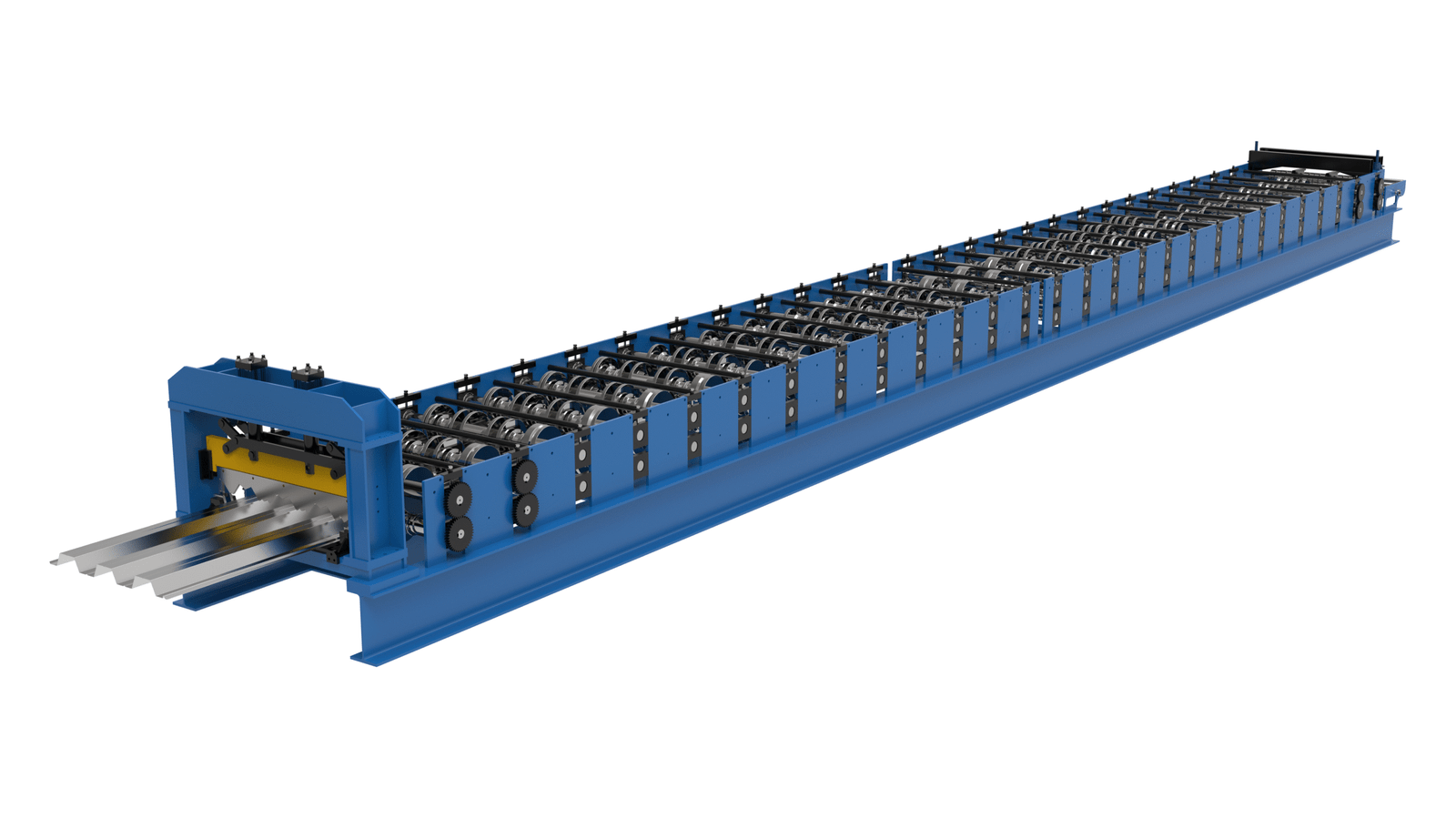

Overview of B-Deck Roll Forming Machine

A B-Deck roll forming machine is a precision-engineered system specifically designed to produce B-Deck metal deck panels. These panels are extensively utilized in the construction industry owing to their optimal balance of strength, lightweight properties, and cost efficiency. Renowned for their robustness, quick installation, and high load-bearing capacity, B-Deck panels serve as a versatile solution for diverse building projects.

B Deck is a structurally efficient, lightweight, and budget-friendly roofing material, favored for its ease of installation. The Verco HSB-36 model (High Shear B Decking) features a 36-inch width and is frequently employed in roofing systems, awnings, canopies, and enclosure gates. Suitable for short to intermediate spans (3–10 feet), the B Deck profile has a 1.5-inch rib height and is offered in galvanized or painted finishes.

Key Specifications of A B-Deck Roll Forming Machine:

-

Deck Type: Roof Deck

-

Panel Type: B Deck (HSB-36)

-

Material Thickness: 22, 20, 18, 16 gauge

-

Rib Height: 1.5 inches

-

Rib Spacing: 6-inch pitch

-

Panel Length: Customizable from 2 to 40 feet

-

Standard Width: 36 inches

Core Components of the B Deck Roll Forming Machine:

-

10-ton hydraulic decoiler with coil trolley

-

Main forming unit (includes feeder, guide system, rollers, and cutter)

-

Control panel

-

Hydraulic power pack

-

Output stacking table

Material Compatibility:

-

Types: PPGI, GI, PPGL, GL

-

Thickness Range: 0.8–1.5 mm (for B Floor Deck)

-

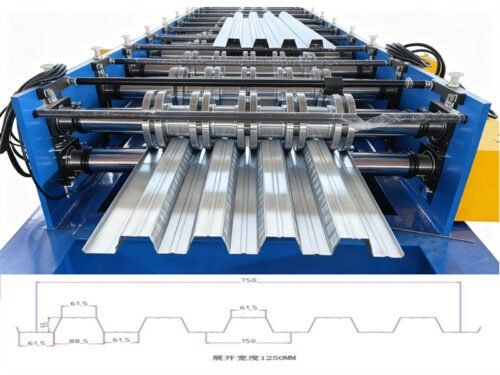

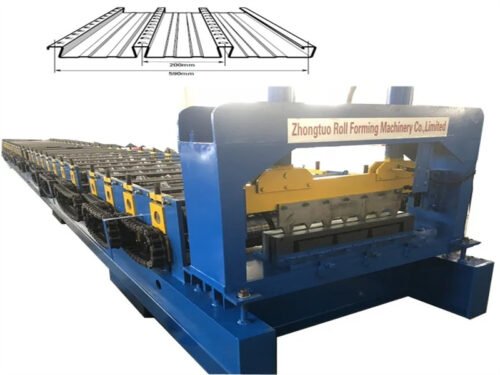

Forming Stages: 24–28 passes

-

Shaft Specifications: 40 CR alloy, 90 mm diameter

-

Roller Treatment: Heat-treated and precision-chromed for longevity

Types of B-Deck Panels

B-Deck metal panels are categorized into two primary variants, each serving distinct purposes:

-

B Roof Deck: A non-composite structural panel with a smooth surface, ideal for supporting built-up roofing systems. Its lightweight yet sturdy design makes it perfect for commercial and industrial roofing applications.

-

B Floor Deck: A composite panel engineered to reinforce poured concrete, commonly used in flooring systems. It ensures structural stability and durability for multi-level constructions.

Applications of B-Deck Roll Forming Machines

These machines manufacture B-Deck panels, which are widely adopted in construction for roofing, flooring, and cladding due to their:

-

Lightweight Design: Facilitates quick installation while maintaining structural integrity.

-

High Load Capacity: Capable of bearing substantial weights, making them suitable for varied architectural needs.

-

Cost-Effectiveness: Reduces overall project expenses by minimizing material and labor requirements.

ZTRFM’s successful deployment of B-Deck roll forming machines underscores its commitment to delivering high-performance solutions for global construction markets. We take pride in advancing projects that demand reliable and economical decking systems.

Technical Specifications of the B-Deck Roll Forming Machine:

-

Material Specifications:

-

Thickness Range: 0.8–1.5 mm

-

-

Decoiler System:

-

Operation Mode: Fully automated

-

Maximum Load Capacity: 10 metric tons

-

-

Main Machine Structure:

-

Number of Roller Stations: 28

-

Shaft Diameter: 90 mm (45# steel)

-

Roller Material: GCR 15, hardened and chrome-plated

-

Frame Thickness: 20 mm

-

Drive Chain: 2-inch pitch

-

-

Cutting Mechanism:

-

Operation: Automatic

-

Blade Material: CR12MOV alloy steel

-

-

Power Requirements:

-

Voltage: Customizable

-

Total Power Consumption: 22 kW

-

-

Control System:

-

Interface: Delta or customized PLC

-

Language Options: English, Chinese, or as required

-

-

Production Speed:

-

Forming Rate: 15–20 meters per minute

-

-

B-Deck Roll Forming Machine

Reviews

There are no reviews yet.