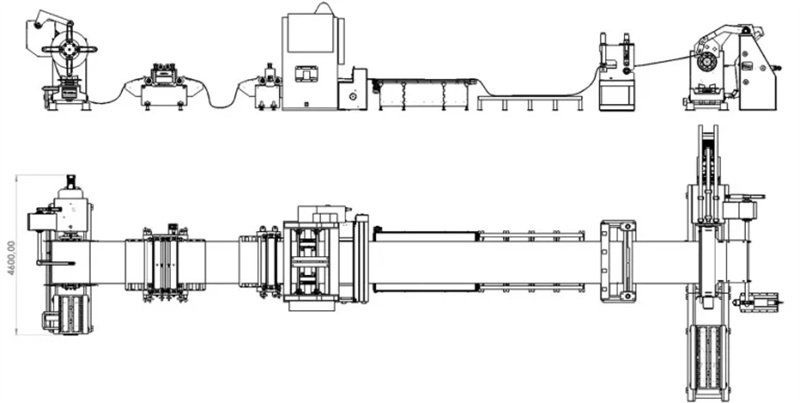

Automatic Metal Perforating Machine Punching Line

Our metal perforating machine is designed for producing perforated metal sheets in a fast, stable, and fully automated way. The equipment supports various raw materials such as aluminum, galvanized steel, stainless steel, cold-rolled steel, and more. Widely used in construction, ventilation systems, filtration, automotive parts, furniture manufacturing, lighting, storage racks, and industrial platforms, this perforated sheet machine punching line delivers high production efficiency and excellent perforation quality.

Main Components of the Perforated Sheet Machine Punching Line

1. Coil Feeding System

The line includes a decoiler, loading trolley, straightener, and servo feeder.

With servo control technology, the feeding accuracy is ensured for consistent perforation patterns and stable production performance.

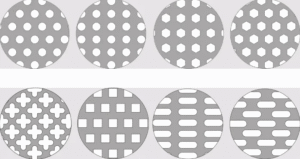

2. Punching / Perforation Press UnitWe customize perforation molds based on the customer’s perforation pattern requirements.

The punching unit adopts an eccentric or hydraulic press (optional), allowing clean hole patterns and long mold life.

3. Cutting or Recoiling System

Depending on the production workflow:

- Coil-to-sheet → Sheets are cut to length and stacked

- Coil-to-coil → Perforated coils are rewound for continuous downstream processing

Both systems are available to match factory workflow needs.

4. Stacking and Receiving System

For sheet output, an automatic stacking table neatly organizes finished sheets for easy packaging and storage.

5. Optional Add-On Units

- Leveling unit

- Corner shearing & bending module

- Slitting module

- Soundproof press room (for low-noise environment)

We tailor the line according to the customer’s expected productivity and material specifications.

Technical Advantages of Metal Sheet Coil Steel Punching

| Advantage | Description |

|---|---|

| Flexible System Configuration | Supports different material thicknesses, sheet widths, punching speeds, and mold designs. |

| Energy Saving Design | Optimized mechanical structure reduces operation energy consumption. |

| User-Friendly Interface | Intuitive control system helps operators start production quickly. |

| High Precision Output | Stable feeding system ensures uniform and precise perforation patterns. |

| Adjustable Production Speed | Options available for high-speed mass production or precision specialty production. |

Applications of Perforated Metal Sheets

- Construction façade panels and ceilings

- HVAC ventilation grilles

- Filtration screens

- Machinery and equipment protection covers

- Furniture panels and lighting components

- Walkways and industrial platforms

- Storage racking systems

Why Choose Our Perforated Sheet Machine Punching Line?

We have years of experience serving factories in the Middle East and Southeast Asia markets.

We understand local production needs, workshop layouts, voltage standards, and operation habits — enabling us to provide the most suitable machine configuration.

Reviews

There are no reviews yet.