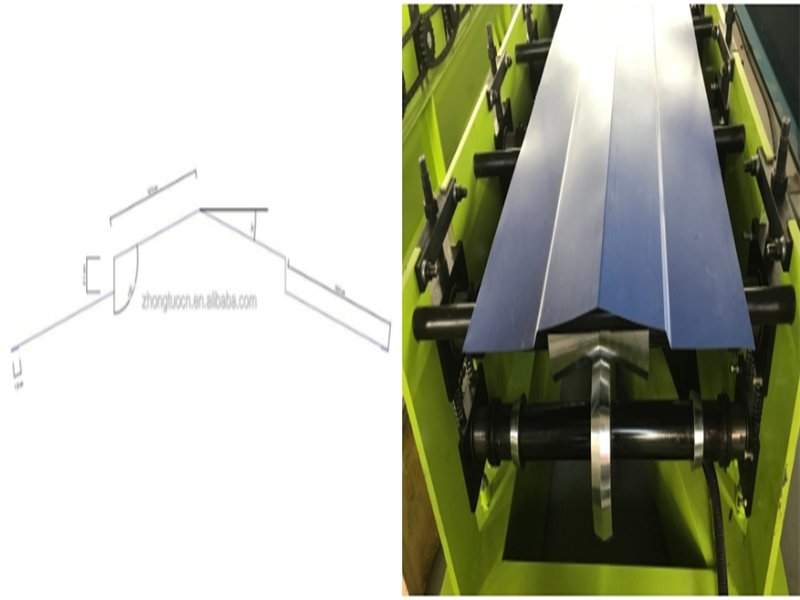

Full Automatic Metal Ridge Cap Hems Roll Former Roof Ridge Cap Roll Forming Machine

The Full Automatic Metal Ridge Cap w/Open Hems Roll Former is a high-performance metal roof ridge cap roll forming machine designed to produce durable, perfectly shaped ridge caps for roofing systems. This advanced ridge cap forming machine delivers precision, speed, and reliability — ideal for professional roofing sheet manufacturers and construction suppliers.

Engineered with an intelligent PLC control system and hydraulic shearing technology, this roof ridge cap forming machine ensures stable operation and consistent quality across batches. The equipment’s open-hem design and computer batch control make it one of the most efficient and cost-effective solutions in the market.

Working Flow

Uncoiler → Feeder → Forming Station → Hydraulic Cutting → Run-out Table

The ridge cap roofing machine operates smoothly with automatic feeding and cutting systems. Its design ensures minimal material waste and low maintenance requirements — operators only need to lubricate the cutting frame periodically.

ZTRFM Resilient Channel Machine

- Formed Material: PPGI, GI (03–0.8 mm)

- 12 roller stations, 7.5 KW × 2 main motors

- Max forming speed: 70 m/min (with punching)

- Hydraulic system: 7.5 KW

- Supports multilingual PLC systems

Key Features of Ridge Cap Roll Forming Machine

- Universal Ridge Cap Production: Suitable for producing various metal roof cap designs.

- Dual Hemming System: Automatically hems both sides of the ridge cap.

- PLC Smart Control: Computerized batch control for precise cutting and length measurement.

- Hydraulic Shear: Ensures clean and accurate cuts without deformation.

- Durable Frame: 350 H steel structure for long-term stability.

- Power System: 220V, 3-phase power supply, with 5,000 lb manual uncoiler included.

- Compact Design: Machine size 21′ x 4′ x 3′, weight 8,000 lbs — perfect for factory or onsite production.

Technical Specifications

| No | Item | Specification |

|---|---|---|

| 1 | Formed Material | PPGI, GI, Aluminum |

| 2 | Material Thickness | 0.3 – 0.8 mm |

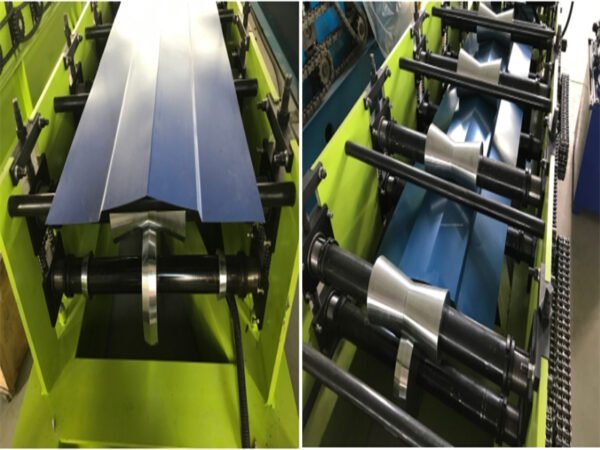

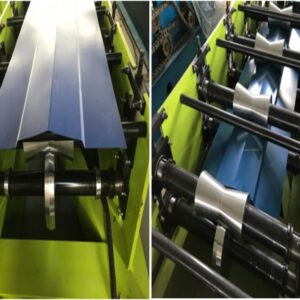

| 3 | Roller Station | 14–22 rows (customizable) |

| 4 | Roller Material | 45# Steel, hard chrome plated |

| 5 | Shaft Diameter | 70 mm solid shaft |

| 6 | Frame Structure | 350# H steel welded frame |

| 7 | Drive Mode | Chain/gearbox transmission |

| 8 | Cutter | Cr12mov material, quenched |

| 9 | Motor Power | 4 KW main motor |

| 10 | Hydraulic Power | 5.5 KW |

| 11 | Control System | PLC (Delta / Siemens / Mitsubishi) |

| 12 | Forming Speed | 12–15 m/min (up to 20 m/min with fly-cutting) |

| 13 | Decoiler | 5-ton manual decoiler |

| 14 | Voltage | 380V 50Hz 3Phase |

| 15 | Transmission | Double chains |

| 16 | Cutting Type | Hydraulic fly cutting |

| 17 | Encoder | Omron |

| 18 | Total Weight | 8 Tons (approx.) |

Application of Ridge Cap Roll Forming Machine

The finished ridge cap profiles produced by this ridge capping roll forming machine metal roof are used for sealing the roof apex, where two slopes meet. This prevents water leakage and provides a seamless, aesthetic, and weatherproof finish.

Roof ridge flashing is essential for protecting against rainwater infiltration that may damage chimneys, ceilings, and inner walls. A properly made roof ridge cap enhances both durability and beauty of roofing systems, making it indispensable in modern architecture and industrial buildings.

⚡ Why Choose ZTRFM Ridge Cap Roll Forming Machines

- Fully Automated Operation: Set length, quantity, and batch in one click.

- Global Compatibility: Used in construction markets across Europe, Asia, and the Middle East.

- Customizable Designs: Supports flat-leg, trapezoidal, or curved ridge profiles.

- Premium Components: PLC from Mitsubishi/Siemens, encoders from Omron.

- Low Maintenance: Built for long-term industrial use with minimal downtime

Ridge Cap Roll Forming Machine

Ridge Cap Roll Forming Machine

More Pictures

Reviews

There are no reviews yet.