High-Speed Main & Auxiliary Keel Roll Forming Machines

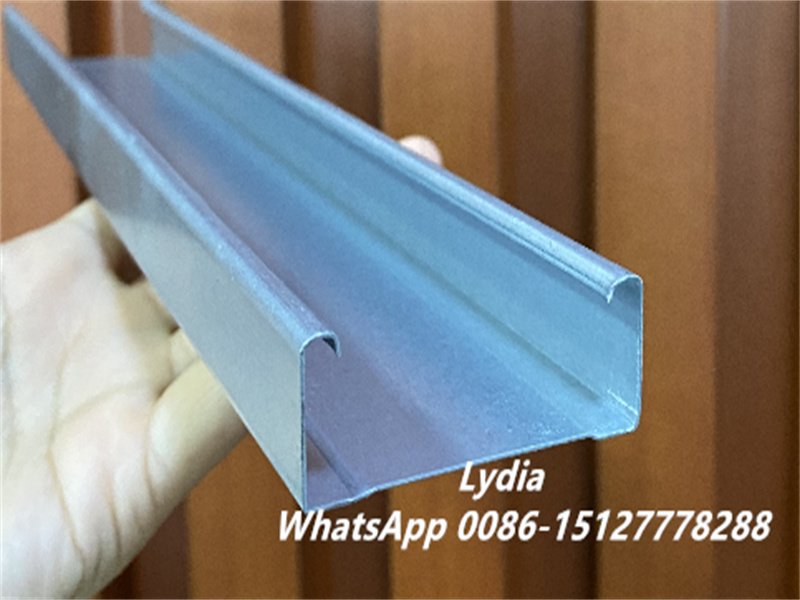

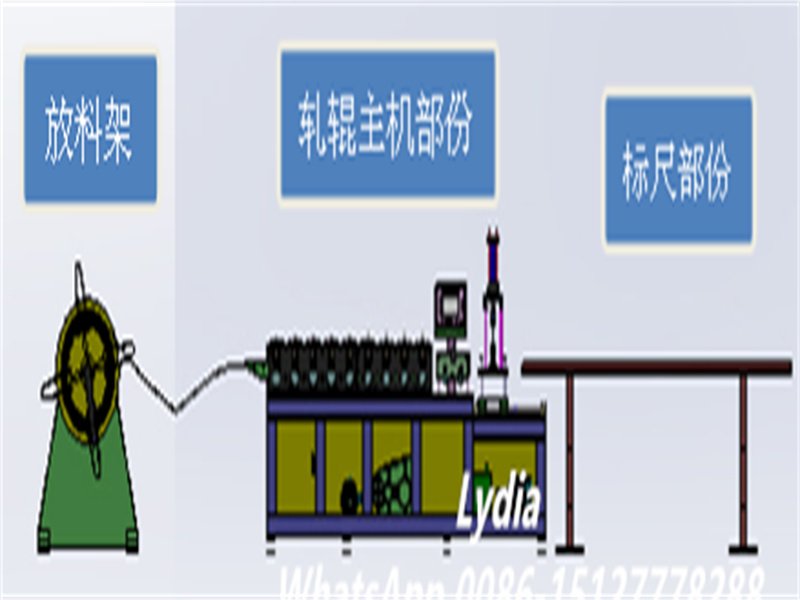

Our 38.50 Main Keel Roll Forming Machine and 50 Auxiliary Keel Roll Forming Machine are precision-engineered production lines designed for the high-speed manufacturing of galvanized steel keels used in light steel frame construction. With advanced gearbox-driven silent transmission, hardened CNC-machined rollers, and fully automated control, these machines deliver excellent performance, accuracy, and efficiency.

Key Advantages of Both Machines

-

High-Speed Production: Up to 80 m/min for maximum output

-

Precision Roll Forming: CNC-machined, hardened rollers ensure perfect profile accuracy

-

Silent & Stable Operation: Gearbox-driven transmission for smooth running

-

Durable Build: Heavy-duty welded frame, annealed for long service life

-

Automated Control: PLC/servo control for high precision and minimal manual intervention

-

Easy Maintenance: Modular design for quick part replacement and adjustments

| Item | 38.50 Main Keel Roll Forming Machine (High-Speed) | 50 Auxiliary Keel Roll Forming Machine (High-Speed) |

|---|---|---|

| Material | Galvanized steel strip | Galvanized steel strip |

| Material Thickness | 0.5–1.0 mm | 0.28–0.6 mm |

| Material Width | As per setup (final width confirmed during commissioning) | As per setup (final width confirmed during commissioning) |

| Finished Profile | Optional embossing available | 49 × 19 mm |

| Line Speed | 25–80 m/min | 25–80 m/min |

| Production Process | Decoiling → Roll Forming → Cutting → Collecting | Decoiling → Roll Forming → Cutting → Collecting |

| Transmission Type | Gearbox-driven silent type | Gearbox-driven silent type |

| Decoiler | Manual expansion core, no power, φ460–520 mm × 400 mm, max OD 1400 mm, max load 3T | Manual expansion core, no power, φ460–520 mm × 200 mm, max OD 1400 mm, max load 3T |

| Rollers | 12 forming stations; Cr12MoV steel; HRC60–62 hardness; CNC-machined (rough turning → quenching → finish turning → precision grinding) | 16 forming stations; Cr12MoV steel; HRC60–62 hardness; CNC-machined (rough turning → quenching → finish turning → precision grinding) |

| Roller Shafts | φ48 mm; 40Cr steel; tempered; four-step precision processing | φ48 mm; 40Cr steel; tempered; four-step precision processing |

| Machine Frame | Welded steel plate structure; annealed; CNC gantry milled | Welded steel plate structure; annealed; CNC gantry milled |

| Roller Supports | 45# precision guide pillars; 54 mm thick uprights; blackened surface; cylindrical roller bearings; dial gauge gap adjustment | 45# precision guide pillars; 54 mm thick uprights; blackened surface; cylindrical roller bearings; dial gauge gap adjustment |

| Forming Motor | 5.5 kW, 380V, 50Hz | 7.5 kW, 380V, 50Hz |

| Hydraulic Shearing | Hydraulic motor 2.2 kW; 1 set of cutting mold | Hydraulic motor 5.5 kW; 1 set of cutting mold |

| Run-out Table | – | 3000 mm with scale; simple platform 1 m wide |

| Electrical System | PIC (Inovance) controller, Inovance touch screen, SICK encoder (Germany), Inovance inverter, tracking servo motor, Schneider components (or equivalent) | PLC (Inovance), Inovance touch screen, SICK encoder (Germany), Inovance inverter, tracking servo motor, Schneider components (or equivalent) |

| Machine Dimensions | Main machine 6800 × 800 × 1200 mm; total length ~15 m; weight ~5–6T | Main machine 8000 × 800 × 1200 mm; total length ~18 m; weight ~5–6T |

Applications of High-Speed Main & Auxiliary Keel Roll Forming Machine

These roll forming machines are ideal for producing light steel frame components used in:

-

Interior partition walls

-

Ceiling grid systems

-

Prefabricated building structures

-

Industrial and commercial construction

Reviews

There are no reviews yet.