Machine Video Demo

Watch the demo video to see:

- The actual running speed of the production line.

- How profile sizes are automatically adjusted by the PLC, from minimum to maximum dimensions

Fully Automatic U Channel Roll Forming Machine for Drywall Framing

The fully automatic U-channel roll forming machine is engineered for high-speed production of drywall U stabilizer channels commonly used in American steel framing systems.

With a top running speed of 70–120 meters per minute, this advanced line provides fully automated operation—from coil loading to finished channel packaging—ensuring stable performance, precision, and reduced labor cost.

This U-channel roll forming line includes:

- 1.5T Double-Head Hydraulic Automatic Decoiler

- Coil Feeding & Leveling Unit

- Precision Roll Forming System (Gearbox Transmission)

- Servo Flying Cutting System

- PLC Control Station with touch screen operation

- Hydraulic Station (YUKEN Standard)

- Fully Automatic Packaging Section

- Tools and Spare Parts Kit

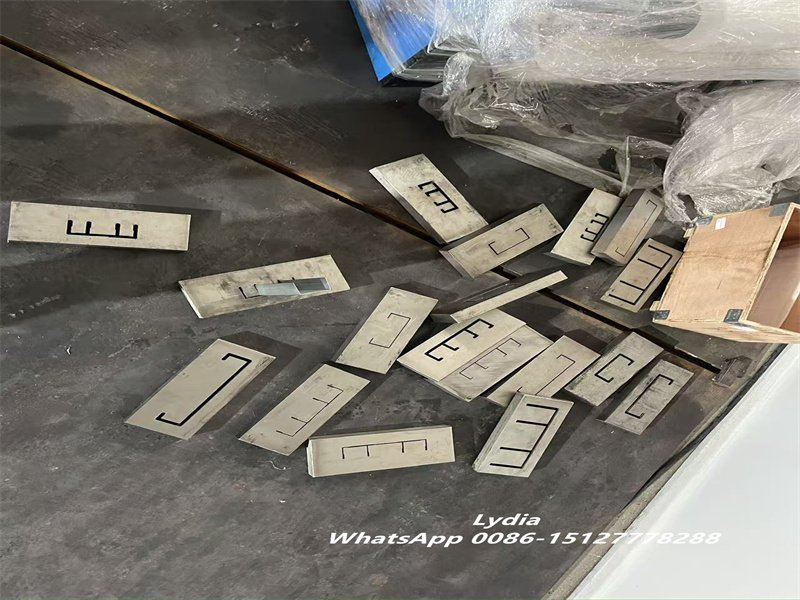

Below is a sample galvanized U-channel drawing profile for your reference.

Efficient Production Line for U Stabilizer Channels

If you need to produce multiple sizes of U channels, we recommend using a Hydraulic decoiler.

Because the line runs at very high speed, it allows you to switch coils quickly without stopping production.

The main forming section is driven by gearbox transmission, ensuring smooth and steady running even at 70 m/min or higher.

The servo-tracking flying shear maintains cutting accuracy while keeping up with production speed between 70–80 m/min.

Packaging is fully automatic, so only one operator is required to load coils and oversee the line, significantly reducing labor requirements and boosting efficiency.

Width Adjustable Metal U Channel Steel Lining Roll Forming Machine

The adjustable-width U-channel roll forming machine is ideal for producing steel lining profiles for PVC door and window reinforcement. It’s designed to meet both small and large production demands across the U.S. construction and building materials industries.

Technical Features

- Adjustable width: 10–40 mm

- Adjustable height: 5–40 mm (depending on coil width)

- PLC control system for automatic size change

- Servo flying shear for precision cutting

- Material thickness: 0.8–1.2 mm galvanized steel or cold-rolled steel

Machine Structure

- Roller Material: GCr15, CNC-machined after overall heat treatment (HRC56–62)

- Main Frame: 8 mm welded steel structure with cast-iron archways

- Roller Shaft Diameter: Ø70 mm, made from 45# steel

- Drive Motor: 15 kW high-efficiency motor

- Transmission Type: Chain drive

- Forming Stations: 9 stations for gradual shaping of the profile

Working Principle

The cold roll forming process gradually bends the flat steel strip into the desired U channel shape through multiple roller stations.

Each forming stage contributes to precise shaping, excellent surface finish, and stable dimensions—ideal for drywall framing systems, steel stud tracks, and window reinforcement profiles.

For detailed specifications, pricing, and machine configuration, contact us directly.

Our team will provide full technical support, installation guidance, and after-sales service across the United States and North America.

Reviews

There are no reviews yet.