1. High-Speed Cassette Keel Roll Forming Machine

The Cassette Keel Roll Forming Machine (High-Speed Model) is designed for the efficient production of cassette keels from galvanized steel strips. It adopts an advanced gearbox silent transmission, ensuring stable operation, reduced noise, and long service life.

Product Specifications

- Material: Galvanized steel strip

- Thickness: 0.5 – 1.0 mm

- Width: Customized according to keel sample or confirmed drawings

- Length: Customized (based on drawings or customer requirements)

- Production speed: 20–35 m/min

- Transmission mode: Gearbox-driven silent type

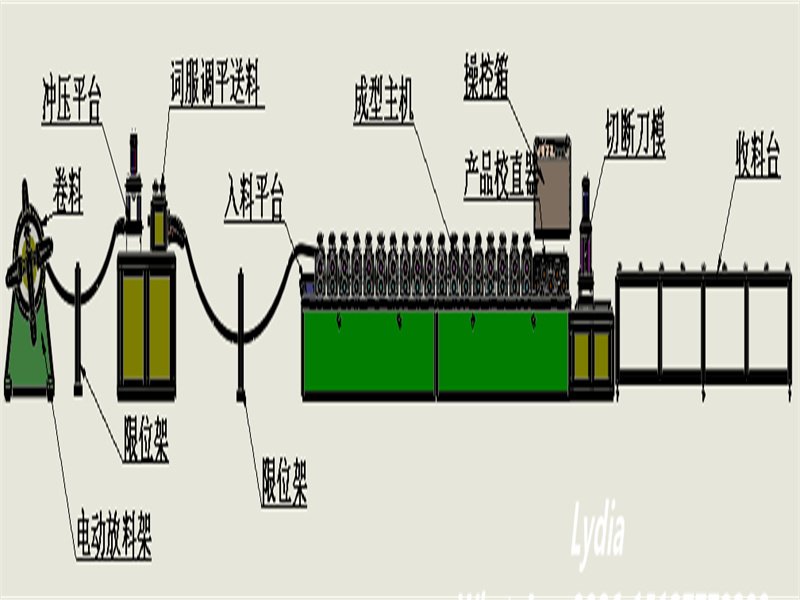

Production Process

Decoiling → Leveling & Feeding → Punching → Roll Forming → Hydraulic Cutting & Press Connection → Collecting

Main Components

- Decoiler (2-in-1): Manual expansion, motorized decoiling, φ460–520mm × 200mm, max coil OD 1400mm, max load 2T

- NC-200 Servo Feeder: Delta or equivalent servo system; thickness 0.3–2.2mm, max width 200mm

- Hydraulic Punching Unit: 63T hydraulic press with one punching mold (extra molds available upon request)

- Rollers: 10 forming stations; Cr12MoV material, quenched HRC60–62, precision CNC machining (rough turning → quenching → fine turning → grinding)

- Roller Shafts: 40Cr, shaft diameter φ48mm, quenched and tempered, precision machining in 4 steps

- Machine Frame: Welded steel plate structure, annealed, processed by CNC gantry milling

- Side Plates: 45# precision guide column, 54mm thickness, blackened surface, roller bearing installation with scale adjustment

- Main Motor: 5.5KW (3-phase, 380V, 50Hz)

- Hydraulic Shearing Unit: 5.5KW hydraulic motor, Huade hydraulic valves, Taiwan hydraulic pump, one set of cutting mold

- Run-Out Table: 3m with ruler + 1m simple platform

- Electric Control System: PLC (Inovance), touch screen (Inovance), encoder (Germany Sick), frequency inverter (Inovance), servo motor (Inovance), electrical components (Schneider or equivalent)

- Machine Size: Total length about 20m

- Machine weight: approx. 4–5T

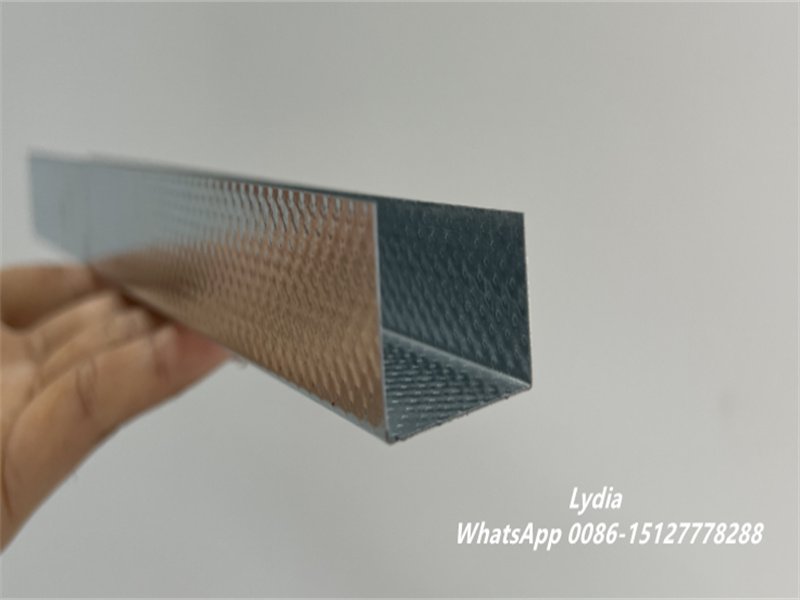

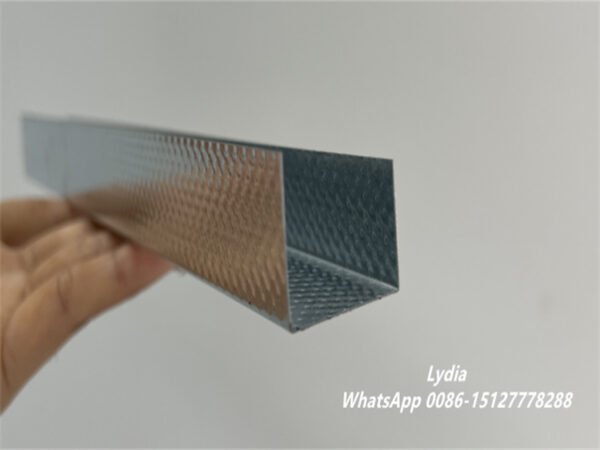

2. High-Speed U-Shape Corner Roll Forming Machine

The U-Shape Corner Roll Forming Machine (High-Speed Model) is specially designed for producing U-shape corner profiles with high efficiency. With a line speed of 60–80 m/min, it ensures mass production capacity while maintaining precise forming quality.

Product Specifications

- Material: Galvanized steel strip

- Thickness: 0.28 – 0.6 mm

- Width: Customized (based on sample or confirmed drawings)

- Length: Customized according to requirements

- Production speed: 60–80 m/min

- Transmission mode: Gearbox-driven silent type

Production Process

Decoiling → Roll Forming → Hydraulic Cutting → Collecting

Main Components

- Decoiler: Manual expansion, non-powered, φ460–520mm × 400mm, max coil OD 1400mm, max load 3T

- Rollers: 12 forming stations; Cr12MoV, quenched HRC60–62, precision CNC machining

- Roller Shafts: 40Cr, φ48mm, quenched and tempered, precision machining in 4 steps

- Machine Frame: Welded steel plate structure, annealed, CNC gantry milling precision finishing

- Roller Support Frame: 45# precision guide column, 54mm thickness, blackened surface, roller bearing with scale adjustment

- Main Motor: 5.5KW (3-phase, 380V, 50Hz)

- Hydraulic Shearing Unit: 4KW hydraulic motor, one set of cutting mold

- Run-Out Table: 3m with ruler

- Electric Control System: PLC (Inovance), touch screen (Inovance), encoder (Germany Sick), frequency inverter (Inovance), servo motor (Inovance), electrical components (Schneider or equivalent)

- Machine Size: Forming unit approx. 5000 × 900 × 1500mm; total line length about 12m

- Machine weight: approx. 4T

3. Both machines are high-speed, precision-engineered roll forming solutions designed for the construction materials industry.

- The Cassette Keel Roll Forming Machine is ideal for producing cassette keel profiles with punching and joining features, suitable for structural and decorative applications.

- The U-Shape Corner Roll Forming Machine offers fast and stable production of U-shaped corners, widely used in light steel framing and drywall systems.

With advanced transmission systems, CNC-machined rollers, servo feeding, and PLC control, these machines ensure high productivity, consistent quality, and reduced material waste, making them a reliable choice for industrial-scale production.

Reviews

There are no reviews yet.