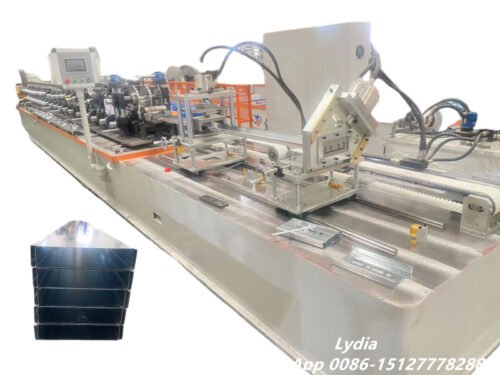

The Double Line Drywall Machine is a high-efficiency, dual-purpose production system used for fabricating drywall stud and track profiles, especially those applied in ceiling and partition installations. This two-in-one system is engineered for precision, speed, and stability, making it ideal for large-scale plasterboard framing production.

Technical Specifications for U-Track Production:

1. Raw Material: Galvanized steel (yield strength: 50 ksi)

2. Available Widths: 43mm, 53mm, 65.5mm, 94mm, 154.5mm (Equivalent to 1-5/8″, 2.0″, 2.5″, 3.625″, 6.0″)

3. Flange Dimensions: 12.7mm to 38mm (0.5″ to 1.5″)

4. Material Thickness: Ranges between 0.45mm and 1.0mm (20–25 gauge steel)

5. Maximum Yield Strength: Up to 80 ksi (550 MPa)

Additional Features:

Integrated 15° bend for structural reinforcement.

Optional pre-punched holes for electrical or plumbing applications.

Ideal for partition frames, suspended ceilings, and light steel framework systems.

Machine Layout & Components:

1. Double-Head Manual Decoiler:

Coil handling: Passive style

Structure: Welded with steel channel base

Capacity: 1.5 tons

Inner coil diameter: Adjustable (450–550mm)

Equipped with a manual braking mechanism

2. Main Roll Forming Unit:

Operating speed: Up to 40 meters per minute

Roller stations: 11 sets on each line (dual line system)

Framework: Reinforced arch-type structure for improved alignment

Base frame: Fully welded steel plates

Motor power: 5.5kW per forming line (total 11kW)

Drive mechanism: Chain-driven

Integrated punching units: One per line for logo/slot punching

Reviews

There are no reviews yet.