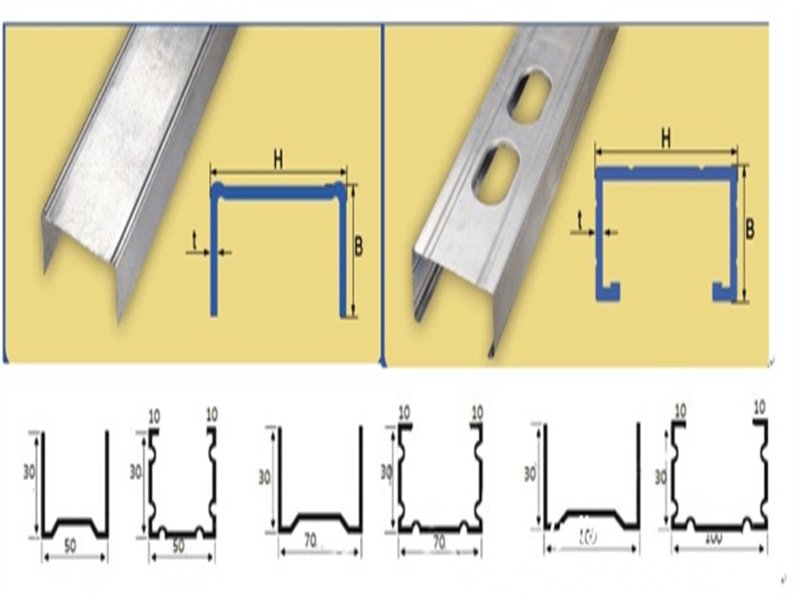

Galvanized Metal Stud and Track Wall Framing Profile Rolling Forming Machine

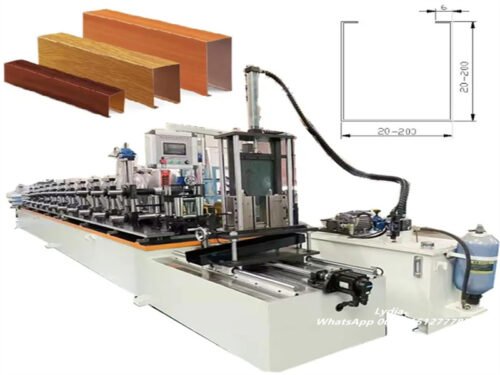

The Galvanized Metal Stud and Track Wall Framing Profile Rolling Forming Machine is a high-efficiency production system for manufacturing metal stud and track profiles used in drywall partitions and suspended ceiling frameworks. It supports continuous automated production with accurate profile dimensions, clean edges, and stable structure performance. This machine works with GI and PPGI steel coils and is suitable for construction contractors, building material factories, and interior system manufacturers.

Machine Advantages of drywall steel framing roll former

- Continuous High-Speed Production

Forming speed ranges from 25 to 80 m/min, ensuring fast output for large-scale projects.

- PLC Automatic Size Adjustment

Profile width and height can be changed directly on the PLC’s touchscreen, improving efficiency during model switching. - Optional Surface Embossing / Dotting

Enhances profile strength and improves anti-deformation performance.

- Servo Flying Shear Cutting System

Cutting and punching occur during motion, allowing smoother production and better length accuracy.

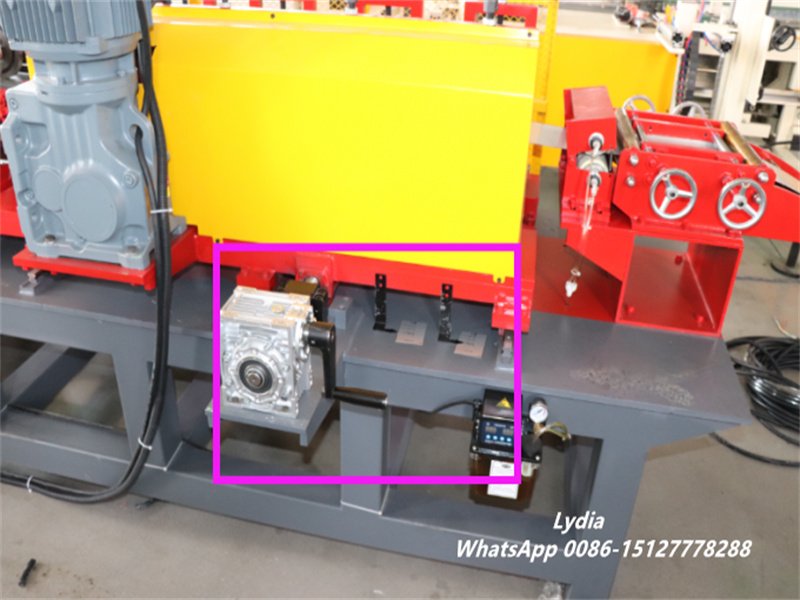

- Stable Power and Hydraulic System

A dual-motor hydraulic station includes a cooling system for reliable long-term operation.

Machine Structure & Specifications of the light steel Frame forming line

| Item | Specification |

|---|---|

| Raw Material | GI / PPGI Steel |

| Thickness Range | 0.5 – 1.3 mm |

| Decoiler | 3 Ton Manual or Automatic |

| Roller Stations | 12 Stations |

| Roller Material | 45# Steel, precision machined |

| Shaft Diameter | 40mm |

| Transmission | Gear-driven dual-motor system |

| Main Motor Power | 7.5 kW |

| Cutting Method | Hydraulic cutting, servo flying shear optional |

| Hydraulic Power | 5.5 kW |

| Cutting Blade | Cr12, heat-treated |

| Length Accuracy | ±1 mm |

| Control System | Siemens / Delta PLC + Touch Screen |

Smart Operation and Safety Design

- The equipment includes both automatic and manual adjustment modes for flexible operation.

- A full protection cover increases operator safety during high-speed forming.

- The finished profiles can be collected on a motorized output table, streamlining packaging and storage.

Applications of the Metal Stud and Track Forming Machine

The finished metal framing profiles are widely used in:

- Gypsum board partition walls

- Office and residential drywall framing

- Light steel keel ceiling systems

- Retail and commercial interior fit-out projects

They provide lightweight structure support with high rigidity and fast installation.

✔ Efficient production for high-volume orders

✔ Easy to switch profile sizes on the same machine

✔ Durable rollers and shafts ensure long service life

✔ Suitable for all major drywall and ceiling system standards

Reviews

There are no reviews yet.