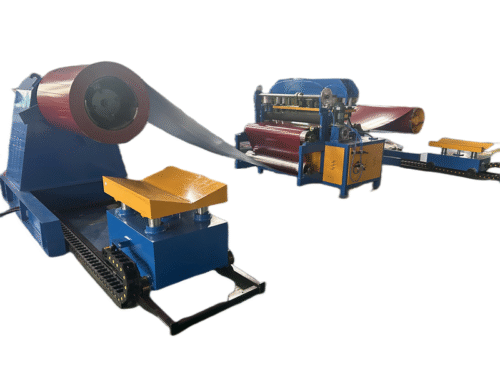

Heavy-Duty Double Head Hydraulic Decoiler for High-Speed Production

A double head decoiler machine is an essential piece of equipment in modern metalworking and stamping lines. It is designed to improve efficiency, reduce downtime, and ensure continuous material feeding. By using two mandrels, the machine allows one coil to work while the other is prepared in advance. This setup greatly shortens coil changeover time and keeps production running smoothly.

Key Features of the Heavy-Duty Double Head Hydraulic Decoiler

-

Fast and Easy Material Loading

The hydraulic decoiler adopts a rotary box structure and a precise brake device. This design ensures quick coil loading and stable unwinding. -

Double Head Hydraulic Decoiler Machine Hydraulic Expansion System

A mandrel inside the main shaft works with an external expansion mechanism. The hydraulic station drives the mandrel and expands the support tiles outward, providing strong and reliable expansion force. When not needed, the mandrel moves in the opposite direction to release the coil.Double Head Hydraulic Decoiler Machine

-

Stable Brake Device

The new brake system uses a moving ring, damping brake ring, and adjusting handwheel. By turning the handwheel, operators can adjust the friction and control the unwinding speed with accuracy. This guarantees smooth and consistent operation. -

Improved Structural Stability

Bearings are placed at both the upper and lower ends of the rotary box. This increases rotational stability and extends the service life of the decoiler.

Working Principle

The double head decoiler machine operates by driving one roll to unwind the metal strip while the other acts as a backup. Once the active roll is finished, the backup roll is quickly connected, minimizing downtime. As a result, workers have more time to load the next spare roll without affecting production speed.

Technical Parameters Double Head Hydraulic Decoiler

-

Applicable Coil Width: 20mm – 300mm

-

Coil Thickness: 0.3mm – 3.5mm

-

Coil Inner Diameter: 450mm – 530mm

-

Coil Outer Diameter: 1200mm

-

Speed: up to 60m/min

-

Mandrel Expansion: Manual or Hydraulic

-

Application: Coil uncoiling for stamping and forming line

Benefits for Manufacturing

-

Reduced Downtime: Quick coil changeover ensures continuous production.

-

Higher Efficiency: Line speed can reach up to 60 meters per minute.

-

Better Reliability: Hydraulic expansion and advanced brake system guarantee stable unwinding.

-

Cost Savings: Less downtime and fewer interruptions lower overall production costs.

Conclusion

The heavy-duty double head hydraulic decoiler is a reliable and efficient solution for modern stamping and forming lines. With advanced hydraulic expansion, precise braking, and dual mandrel operation, it ensures smooth coil handling and continuous high-speed production. For manufacturers aiming to maximize throughput and reduce downtime, the double head decoiler machine is an ideal choice.

Reviews

There are no reviews yet.