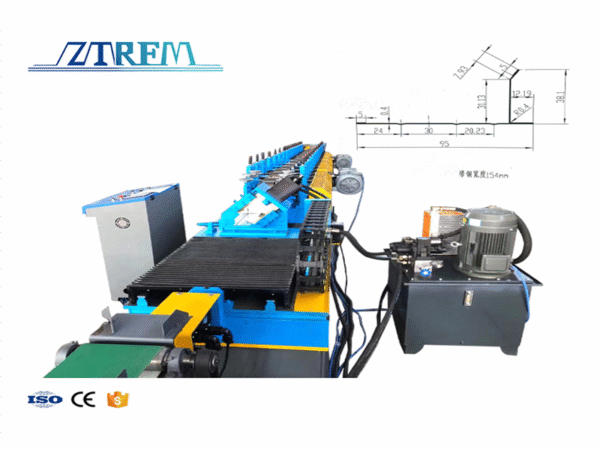

Product Overview of the Fascia Drip Edge Roll Forming Machine

The Fascia Drip Edge Roll Forming Machine is a high-efficiency industrial solution tailored for the needs of metal fabrication companies across the United States. Built for speed and precision, this equipment can manufacture fascia drip edge profiles at up to 50 meters per minute, making it ideal for large-scale production in the roofing and construction industries. Produced by ZTRFM, the machine emphasizes reliability, easy installation, and continuous performance.

This advanced roll former incorporates top-tier components such as PLC controllers, motors, gearboxes, bearings, and hydraulic systems to ensure consistent quality and minimal downtime. With its hydraulic track cutting system, the machine delivers smooth and accurate cuts, helping to reduce material waste and optimize productivity.

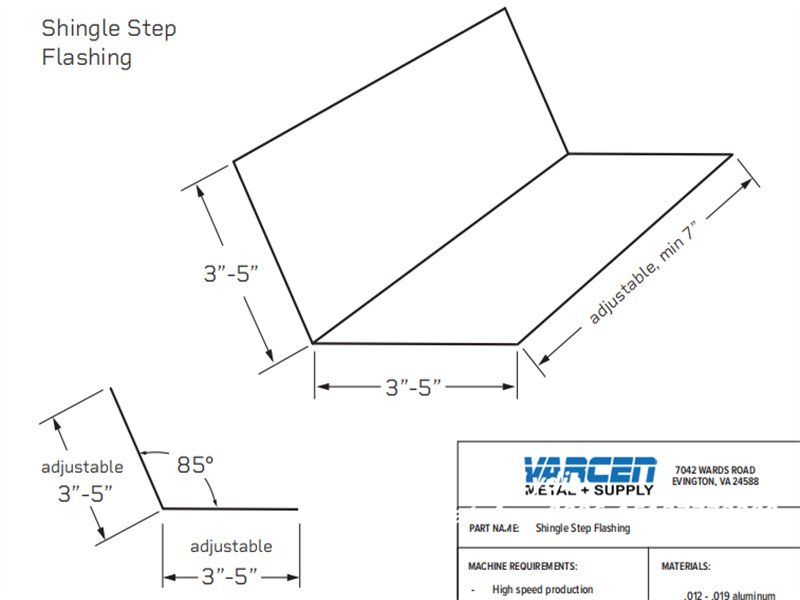

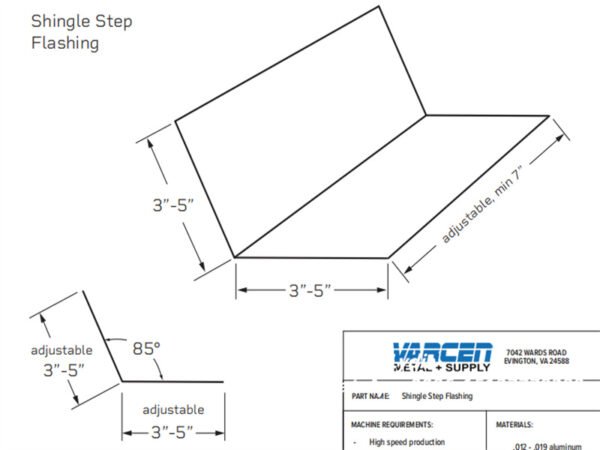

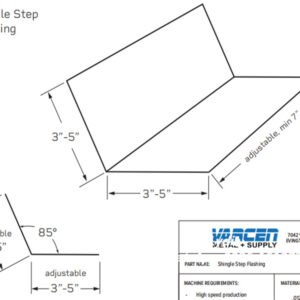

The draw profile:

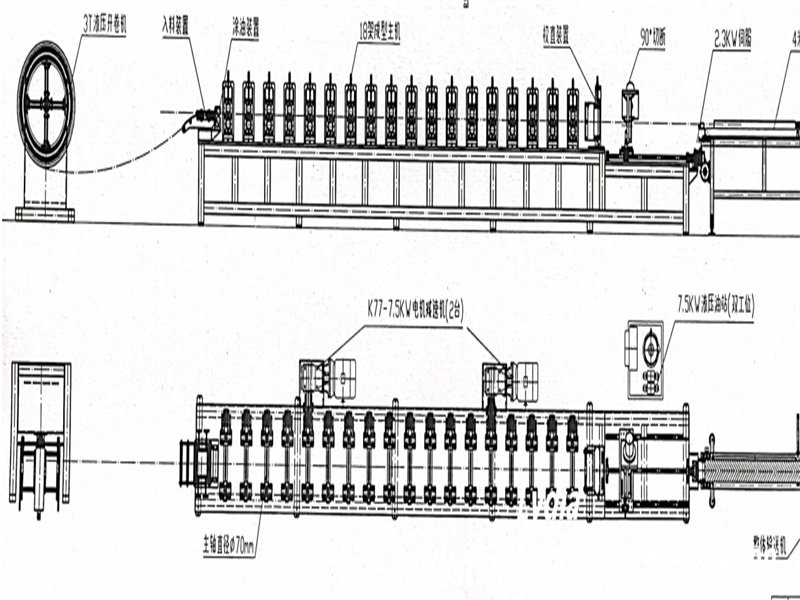

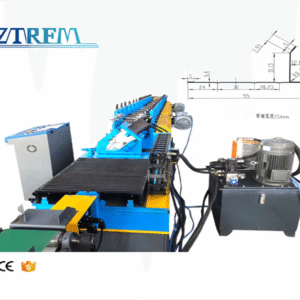

The flow work:

Zhongtuo offers lifetime technical support, ensuring every customer receives ongoing assistance and operational stability. Each unit is manufactured to meet exact client specifications and is shipped directly from our production facility to locations throughout the USA.

Applications of The Fascia Drip Edge Roll Forming Machine

Widely used in American roofing and construction markets, the Fascia Drip Edge Roll Forming Machine produces essential metal flashing and trim elements. These profiles play a vital role in protecting buildings by channeling rainwater away from structural surfaces, helping to prevent moisture infiltration and extend the lifespan of roofing systems.

Technical Specifications of The Fascia Drip Edge Roll Forming Machine

| Parameter | Details |

|---|---|

| Condition | Brand new |

| Stock Number | 47846 |

| Material | Cr12 hardened steel |

| Surface Coating | Chrome-plated for corrosion resistance and durability |

| Servo Motor Brand | Siemens or equivalent – ensures high-speed accuracy |

| Control System Brand | Mitsubishi, Delta, or Siemens |

| Cutting Type | Post-cutting method for exact profile lengths |

| Machine Length | Ranges from 6 to 10 meters (customizable) |

| Main Motor Power | 7.5 kW (adjustable based on needs) |

| Voltage Options | 220V / 380V / 440V – compliant with U.S. state-level power standards |

| User Interface | Customizable and easy to operate |

| Production Speed | Adjustable: typically 20 to 30 meters per minute |

| Supported Materials | Galvanized steel, aluminum, stainless steel |

| Material Thickness Range | 0.4 mm to 0.8 mm |

| Standard Profile Width | From 20 mm to 50 mm |

| Custom Length Options | Tailored to customer requirements |

| Material Gauge | 22–26 gauge |

| Automatic Stacker | Streamlines the collection of formed profiles |

| Remote PLC System | Enables off-site control and monitoring |

| Coil Handling Equipment | Includes coil car, tipper, uncoiler, and recoiler for efficient material flow |

| Daily Maintenance | Check roller and blade conditions |

| Weekly Service | Lubricate parts and remove debris |

| Monthly Checks | Align rollers, calibrate sensors |

| Annual Overhaul | Replace worn components, update PLC firmware |

Reviews

There are no reviews yet.