Common Types of Roofing Roll Forming Machines

What is a Roll Forming Machine Process?

Roll forming is a manufacturing process where a continuous metal strip passes through a series of roller stations to form a desired profile or shape.

Suitable Materials for Roll Forming

-

Steel / Stainless Steel – high corrosion resistance due to chromium content

-

Galvannealed Steel – coated with a zinc-iron alloy

-

Aluminum – light, malleable, and corrosion-resistant

-

Brass – copper-zinc alloy with metallic luster and corrosion resistance

-

Copper – highly conductive and ductile

-

Composite Materials – engineered materials for specialized use

Types of Roofing Roll Forming Machines

-

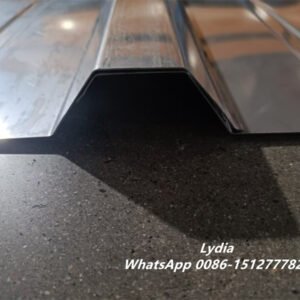

Standard Roof Roll Forming Machine

Also known as trapezoidal, rib-type, Spandek, IBR panel makers. Available in profiles with 4, 5, 6, 7, 9, 11, or 13 ribs, depending on needs. -

Corrugated Roll Forming Machine

Produces corrugated sheets widely used in roofing, wall cladding, fences, and screens in residential, industrial, and public buildings. -

Tile Roofing Roll Forming Machine

Creates various tile profiles (e.g., classic, master, Roman, wave) through step-by-step rolling and pressing, achieving aesthetic appeal suitable for villas or penthouses. -

Double Deck Roll Forming Machine

Capable of forming two different roof profiles simultaneously—such as trapezoidal + cladding, corrugated + tile—to save space and cost. -

Seamlock (Standing Seam) Roll Forming Machine

Produces seam-locking metal panels noted for longevity and ventilation benefits; commonly used for premium roofing solutions. -

Portable Roofing Roll Forming Machine

Compact and mobile design, allowing on-site production of metal panels without pre-fabrication. Features:-

Transportable and flexible for field use

-

On-site assembly and continuous rolling

-

Reduces logistical efforts and installation time

-

Additional Roll Forming Equipment Categories

-

Pressing Curve Forming Machines – standard, double, and pressing & cutting styles for curved profiles

-

Channel Roll Forming Machines – C, U, V, and Z shapes for structural profiles

-

Rack Roll Forming Machine – for pallet or rack components

-

Capping (Nok) Roll Forming Machines – tile capping, longspan, and manual types

-

Truss Roll Forming Machines – C-truss, batten, and combined structures

-

Slitter & Cutter Units – for slitting and length cutting metal coils

-

Decoiler / Uncoiler – optional coil feeders with or without coil cars

-

Ceiling & Drywall Roll Forming – ceiling, automatic C-stud & U-track forming

Reviews

There are no reviews yet.