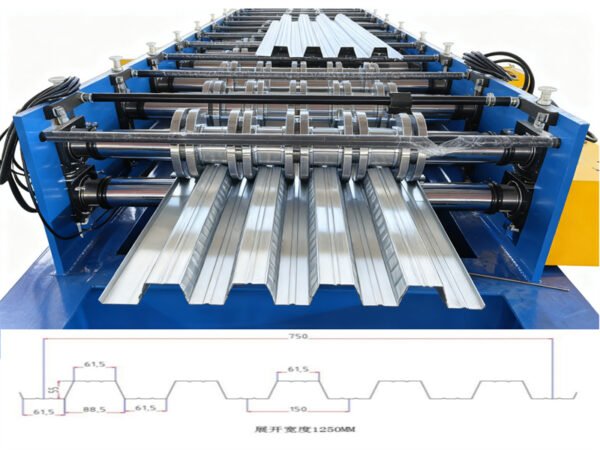

Floor Deck Roll Forming Machine for Steel Construction Projects

The floor deck roll forming machine is designed for producing high-strength metal decking sheets widely used in high-rise buildings, industrial plants, and commercial complexes. It ensures fast production, precise forming, and long service life. Moreover, the machine reduces manual labor and improves efficiency in large construction projects.

Key Features of the Steel Decking Sheet Production Line Machine

- Automatic control system with Siemens PLC and touch screen for easy operation.

- Hydraulic cutting with SKD11 blades ensures clean edges and longer blade lifespan.

- Hardened Cr12MoV rollers provide high wear resistance and stable performance.

- Compact design allows quick installation and low maintenance costs.

- Exported to more than 90 countries, trusted by international contractors.

Technical Parameters of the Metal Deck Sheet Machine

| Parameter | Specification |

|---|---|

| Coil Material | Galvanized steel, Galvalume, or Aluminum |

| Thickness | 0.8 – 1.5 mm |

| Coil Width | 1000 – 1250 mm |

| Forming Stations | 22 – 28 |

| Production Speed | 12 – 15 m/min |

| Motor Power | 11 – 22 kW (Siemens / ABB optional) |

| Cutting System | Hydraulic cutting, SKD11/D2 blades (re-grindable) |

| Control System | Siemens PLC + Touch Screen |

| Voltage | 380V / 50Hz / 3Phase (customizable) |

| Machine Size | 10,000 × 1,800 × 1,500 mm (approx.) |

Advantages of a high-strength floor decking machine.

In addition to its technical strengths, the steel deck roll forming machine offers several advantages:

- It delivers high precision forming with minimum tolerance.

- It allows fast changeovers for different deck profiles.

- It significantly lowers operating costs while maintaining reliability.

- It supports large-scale industrial and commercial construction projects.

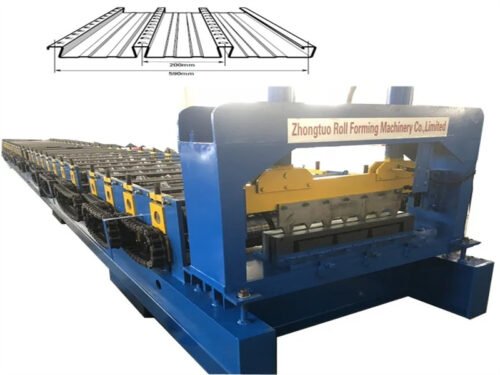

Machine Components

| Component | Description |

|---|---|

| Decoiler | Manual or automatic, up to 5 tons capacity |

| Feeding & Leveling Unit | Straightens coil before roll forming |

| Roll Forming Stations | Hardened rollers with high precision shafts |

| Hydraulic Cutting Device | Accurate cutting to length with no material waste |

| PLC Control Cabinet | Siemens/Delta/Omron brands, touch screen, user-friendly interface |

| Run-out Table | 3–6 m, manual or automatic stacker optional |