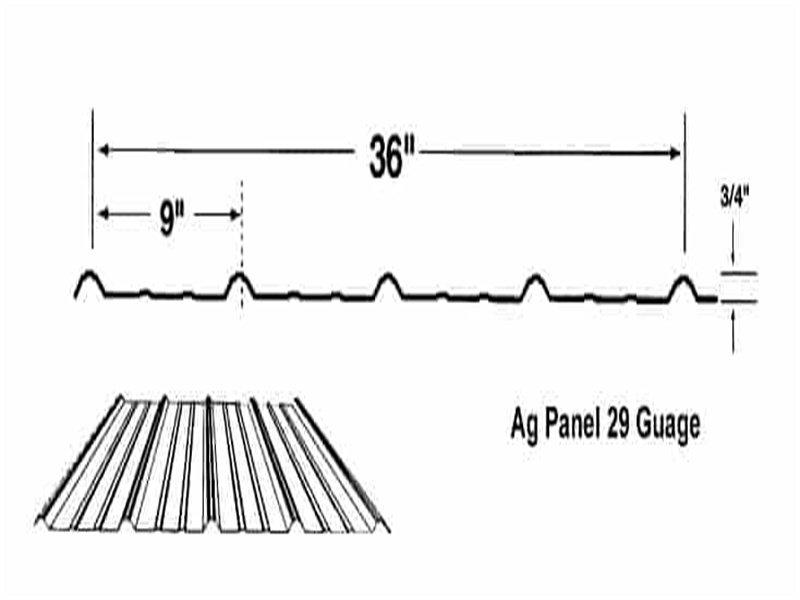

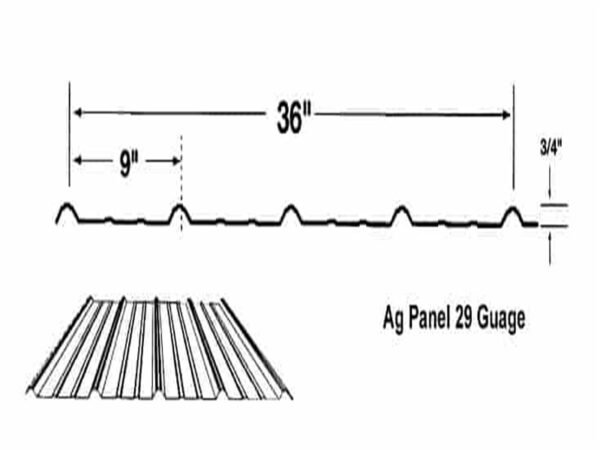

AG Panel, also known as Tuff-Rib Panel, is a low-profile, cost-effective metal roofing method designed for residential, commercial, and agricultural use. Manufactured from 0.3–0.8 mm-thick material, it offers excellent durability and versatility. With a fastener design for secure installation, available in both standard and custom trim options, this panel is ideal for roofing, siding, portable buildings, and post-frame structures, making it a reliable choice for a wide range of construction projects.

| Component | Description |

|---|---|

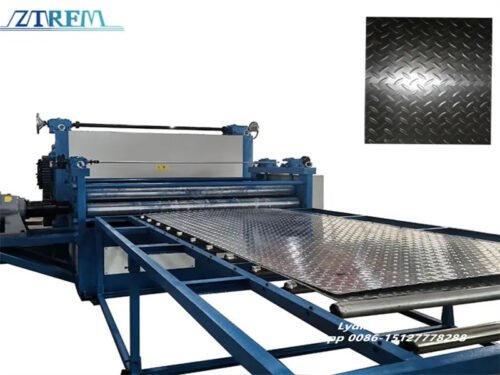

| Uncoiler | 5 Ton capacity; Manual or Automatic |

| Feeding & Guiding Device | Ensures material alignment before forming |

| Pre-shearing Device (Optional) | Manual, Electric, or Hydraulic |

| Roll Forming Machine | Multiple roll stand designs available |

| Cutting Device | Hydraulic or Electric |

| Control Panel | With remote controller |

| Hydraulic Station | Includes cooling fan to reduce oil temperature |

| Collection Table / Auto Stacker | Customizable length as required |

Technical Specifications

| Parameter | Specification |

|---|---|

| Production Process | Uncoiling → Feeding & Guiding → Roll Forming → Cutting → Collecting → Packaging |

| Uncoiler Capacity | 5 Ton |

| Coil Thickness | 0.3 – 0.8 mm |

| Applicable Materials | PPGI, GI, Aluzinc, Stainless Steel, Aluminum |

| Roller Material | 40Cr, Heat-treated and Chromed |

| Forming Stands | 18 |

| Shaft Material & Size | 42Cr, 80 mm diameter |

| Motor Power | 7.5 kW |

| Hydraulic Cutting Power | 5.5 kW |

| Transmission Type | Chain or Gearbox |

| PLC Brand | Siemens or Delta |

| Encoder Brand | Omron |

| Production Speed | 15–20 meters per minute |

Reviews

There are no reviews yet.