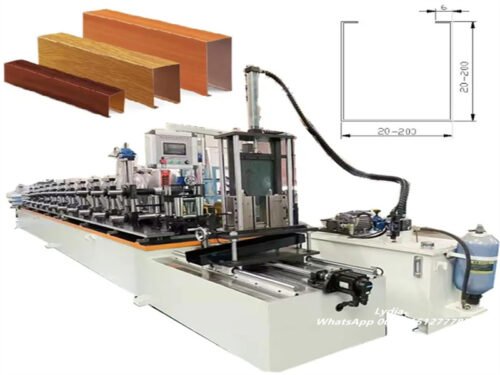

CNC Adjustable Metal Stud Roll Forming Line

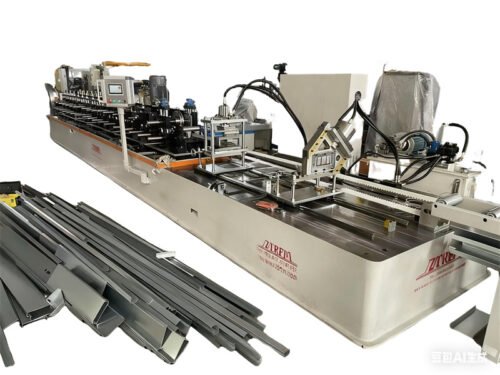

The Universal Vertical Stud Roll Forming Machine (High-Speed Model) is a state-of-the-art solution for producing various steel studs and tracks with high efficiency and accuracy. Designed for versatility, this roll forming line can process multiple stud sizes with CNC adjustment, making it an excellent choice for industrial and construction applications. Moreover, its advanced drive system ensures stable operation, while the cutting-edge hydraulic shear guarantees clean and precise cuts.

Product Features of High-Speed Drywall Stud & Track Production Equipment

To begin with, this machine is capable of forming galvanized steel studs with thicknesses ranging from 0.3 mm to 1.2 mm. Additionally, it supports CNC-adjustable stud specifications, which means that users can easily switch between different product sizes. With six sets of cutting molds included, it can produce up to six different product specifications, and if more are needed, additional molds can be purchased.

Another important point is the production speed. While punching, the line can achieve 25–55 m/min, and without punching, it can reach 25–70 m/min, ensuring excellent productivity.

Production Flow

The production process is designed for simplicity and efficiency:

Decoiling → Roll Forming → Punching → Cutting → Collecting

Furthermore, the forming machine adopts a gearbox-driven silent transmission system, which not only improves durability but also reduces operational noise.

Technical Specifications metal stud roll forming machine for the construction industry

Here are the detailed technical parameters of the Universal Stud Roll Forming Machine:

| Component | Description |

|---|---|

| Machine Name | Universal Vertical Stud Roll Forming Machine |

| Material | Galvanized Steel Strip |

| Material Thickness | 0.3–1.2 mm |

| Material Width | According to stud dimensions |

| Product Specifications | CNC adjustable; 6 sizes with 6 cutting molds |

| Production Speed | Punching: 25–55 m/min; Non-punching: 25–70 m/min |

| Decoiler | Manual expansion, φ460–520 mm × 400 mm, Max. coil OD 1400 mm, Max. load 3T |

| Rollers | 16 forming stations, Cr12MoV material, HRC 60–62, precision CNC machining |

| Roller Shaft | φ55 mm, 40Cr steel, quenched and tempered, precision ground |

| Machine Frame | Welded steel plate, annealed, CNC gantry milling processed |

| Support Stands | Q235A, 48 mm thickness, equipped with roller bearings and scale adjustment |

| Forming Motor | 15 kW, 380V/50Hz, domestic brand |

| Hydraulic Shear | 5.5 kW motor, 1 cutting mold |

| Runout Table | 3000 mm with 1 m wide platform |

| Control System | PLC (Inovance), HMI (Inovance), Encoder (Sick Germany), Inverter (Inovance), Servo Motor (Inovance), Electrical Components (Schneider) |

| Machine Dimensions | Main forming machine: 8000 × 1400 × 1200 mm |

| Total Footprint | 18 m |

| Machine Weight | Approx. 8–9T |

Key Advantages of drywall stud and track roll forming line

- High Versatility: CNC adjustment allows flexible production of different stud sizes.

- Durable Components: Rollers made of Cr12MoV ensure long life and precision.

- Stable Operation: Gearbox transmission provides smooth and silent performance.

- Advanced Control System: PLC with touch screen and servo motor for easy operation.

- High Efficiency: Speed up to 70 m/min, perfect for mass production.

- Reliable Cutting: Hydraulic shear delivers clean and accurate cuts.

Application

Thanks to its efficiency and precision, the Universal Stud Roll Forming Machine is widely used in the construction and building materials industries. It is particularly suitable for producing vertical studs and tracks for partition walls, ceilings, and other steel framing systems.

In summary, the Universal Vertical Stud Roll Forming Machine (High-Speed Model) is a cost-effective, reliable, and versatile solution for modern construction projects. With CNC-adjustable specifications, high-speed operation, and a robust design, it not only increases production efficiency but also ensures consistent product quality.

Whether you are a large construction material supplier or a steel processing manufacturer, this machine will greatly enhance your production capabilities.

Reviews

There are no reviews yet.