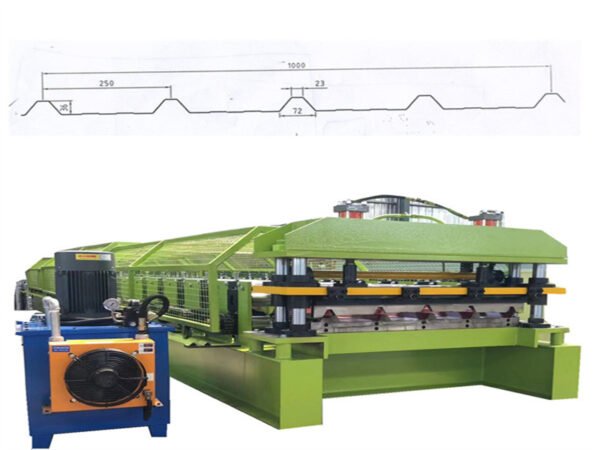

IBR Metal Roofing Sheet Rolling Machine

The IBR metal roofing sheet machine is engineered to manufacture roofing sheets fully automatically.

Roofing projects in Egypt provide durable sheets that can be used as a standalone roofing material or as cladding for buildings.

Our machines deliver high precision, efficiency, and long service life, ensuring your roofing business benefits from excellent performance.

Applications of IBR Roofing Sheets

IBR roofing sheets are widely used in industrial, commercial, and residential buildings.

They are valued for their strength, weather resistance, and excellent drainage.

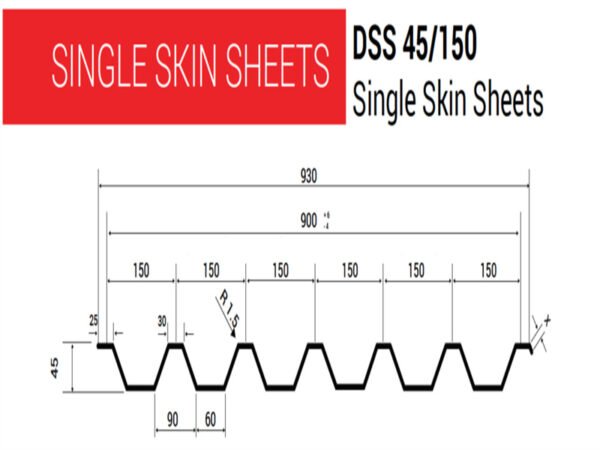

Our IBR sheet rolling machines can produce the most popular IBR designs such as 686 and 890 profiles, which are commonly applied in African markets.

Technical Design of IBR Metal Roofing Sheet Machine

Feeding Unit

- Guiding rollers for accurate sheet feeding.

- Welded steel platform for stability.

- Feeding width adjustable by handwheels.

Roller & Shaft System

- Shafts: 45# steel, diameter 75 mm, tempered for hardness.

- Rollers: 45# steel with chrome plating, anti-wear and anti-rust.

- 20 forming stations, working speed approx. 20 m/min.

Machine Frame & Transmission

- Welded frame with 350# H-beam base.

- Main power: 5.5 kW motor.

- Chain drive with cover; lubrication required.

- Rust-proof spacers and pull rods.

Cutting Device

- Hydraulic cutting system connected with punching unit.

- Blade material: Cr12 with heat treatment (58–62 HRC).

- Length controlled by encoder, tolerance ±1.5 mm.

- Hydraulic power: 5.5 kW, working pressure 12–16 Mpa.

Control System

- PLC: Siemens or Panasonic.

- Frequency converter: Yaskawa; encoder: Omron.

- Main electric components: Schneider.

- Touch screen (MCGS) with English/Chinese interface.

- Voltage: 415V, 50Hz, 3 phase.

- Automatic stop after completion of cutting program.

Optional Equipment

To meet different production needs, the following devices can be supplied:

- Hydraulic decoiler (5T, 7T, or customized). Manual decoiler available free of charge.

- Stacker: 6 m or 12 m. Manual stacker available on request.

Advantages of IBR Roofing Sheet Machine

- Dual-purpose design: one machine produces two roof models, saving cost and space.

- High efficiency: production speed 20–45 m/min, up to 18,900 meters per 8-hour shift.

- Durable structure: machine weight 13–15 tons, solid 75 mm shafts, heat-treated cutting frame.

- Precision forming: CNC-processed rollers, gantry-milled base for smooth forming.

- Easy operation: Mitsubishi or Siemens system, safe and user-friendly.

- Excellent service: engineers available for installation and worker training.

Production Line Layout

Uncoiling → Feeding & Guiding → Roll Forming → Cutting → Collecting

Customer Cases

Our IBR sheet machines have been successfully installed in Egypt, Malawi, and other countries.

Many customers also purchased complementary equipment such as curving machines, corrugated sheet machines, and ridge cap forming machines, expanding their roofing product lines.

Reviews

There are no reviews yet.