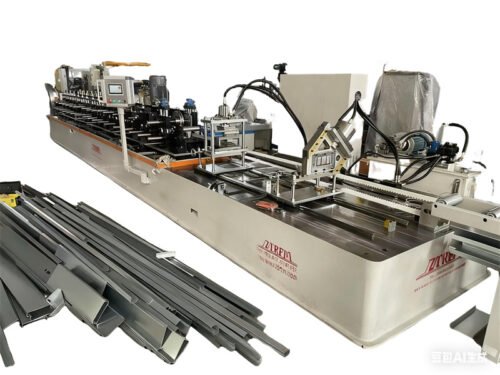

Ceiling T Bar Roll Forming Machine – Flat T & Black T Combined Production Line

Suspended ceiling systems appear in commercial buildings, offices, airports, schools, and public facilities. They create a clean and organized ceiling surface while hiding pipelines, wires, and lighting structures. In these systems, T-bars (T-grids) play the main structural role. The Main T and Cross T profiles work together to support ceiling tiles and form the entire framework.

Our Ceiling T Bar Making Machine produces both profile types efficiently and with stable precision.

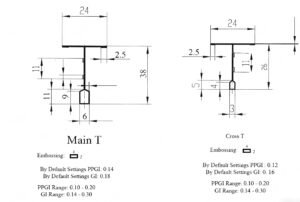

Main T & Cross T Profile Dimensions

Main T

- Top Width: 24mm

- Total Height: 38mm

- PPGI Thickness: 0.10–0.20mm

- GI Thickness: 0.14–0.30mm

Cross T

- Top Width: 24mm

- Total Height: 26mm

- PPGI Thickness: 0.10–0.20mm

- GI Thickness: 0.14–0.30mm

We can add surface embossing to increase stiffness and improve appearance.

Working Process

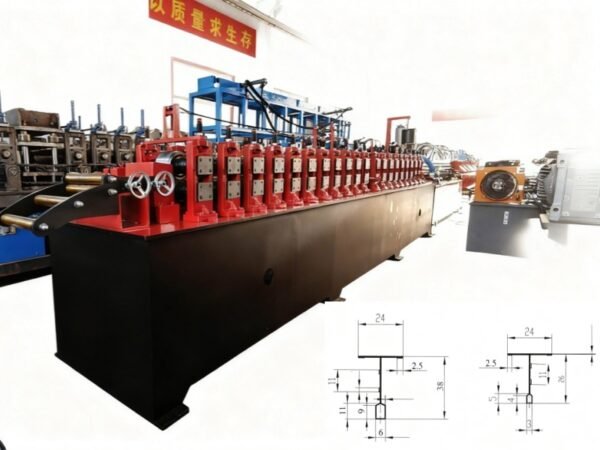

The T-bar roll forming machine includes:

- Decoiler

- Leveling and forming system

- Punching system

- Servo hydraulic cutting system

- Automatic output table

Process Flow:

- Load steel coil → start feeding.

- Roll forming molds shape the profile.

- Hydraulic punching forms hanger holes or logo marks.

- Servo cutting system trims the T bar to the required length.

- Finished products move to the output table for packing.

Why the Machine Can Produce Both Flat T Bar and Black Center T Bar

The machine contains 21 forming stands.

Stand No.18 and No.19 control whether the center decorative groove appears.

| Setting | Result |

|---|---|

| Close the roller gap | The rollers press a black center groove → Produces Black T Bar |

| Open the roller gap | The profile passes smoothly → Produces Flat T Bar |

➡ You do not need to change rollers

➡ Switching takes only 3–5 minutes

This flexibility helps one production line serve multiple market standards.

Production Capacity

| Profile Type | Cutting Length | Output Efficiency | Forming Speed |

|---|---|---|---|

| Main T | 3.6m | 1 piece per cycle | Up to 35m/min |

| Cross T | 0.6m ×2 pieces / cycle or 1.2m ×1 piece | High output efficiency | Up to 25m/min |

Advantages of Our Suspended Ceiling Machine

- Punching and cutting happen in one pass, ensuring high accuracy and clean edges.

- High forming speed suits mass production requirements.

- One machine covers two T bar styles — flat and black center — with fast adjustment.

- We use GCr12MoV/GCr15 hardened rollers and 40Cr heat-treated shafts for long service life.

- Optional logo stamping available for brand reinforcement.

Reviews

There are no reviews yet.